A mechanical strength testing device

A technology of mechanical strength and testing device, applied in the direction of measuring device, strength characteristics, testing material hardness, etc., can solve the problems of wasting testing manpower and testing time, inaccurate testing process, and reducing work efficiency, saving labor and testing Time, the test process is safe and reliable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

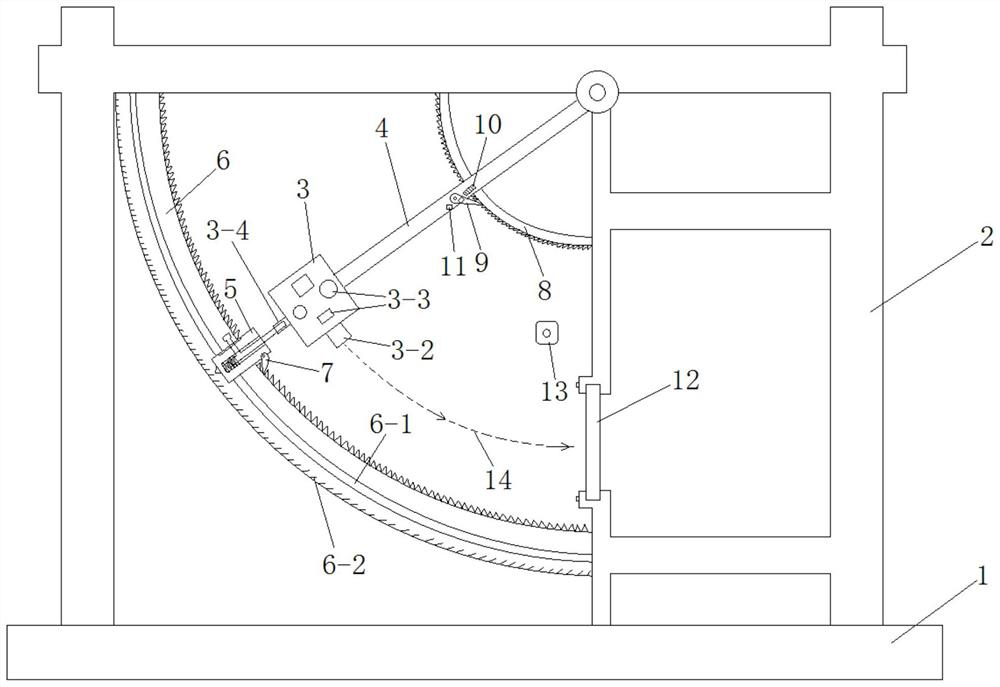

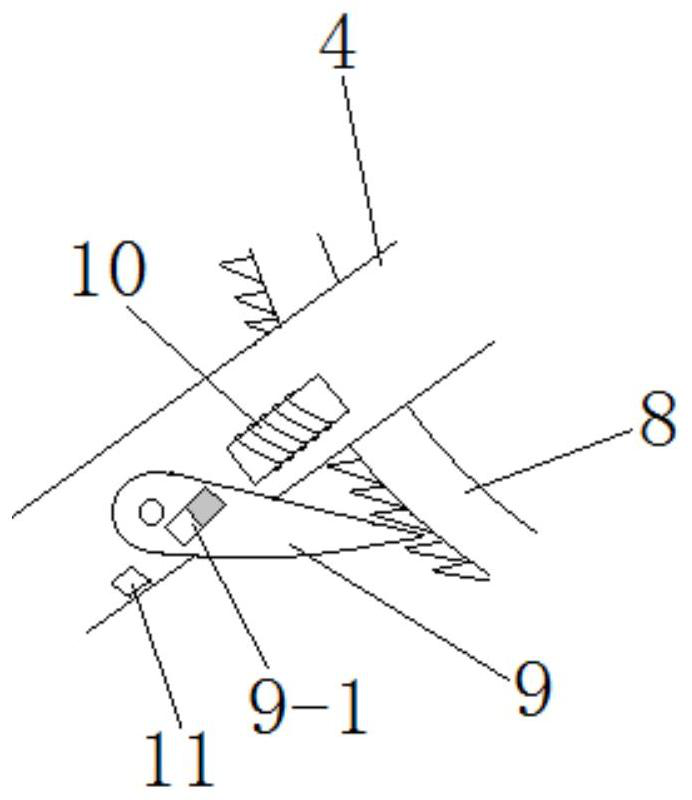

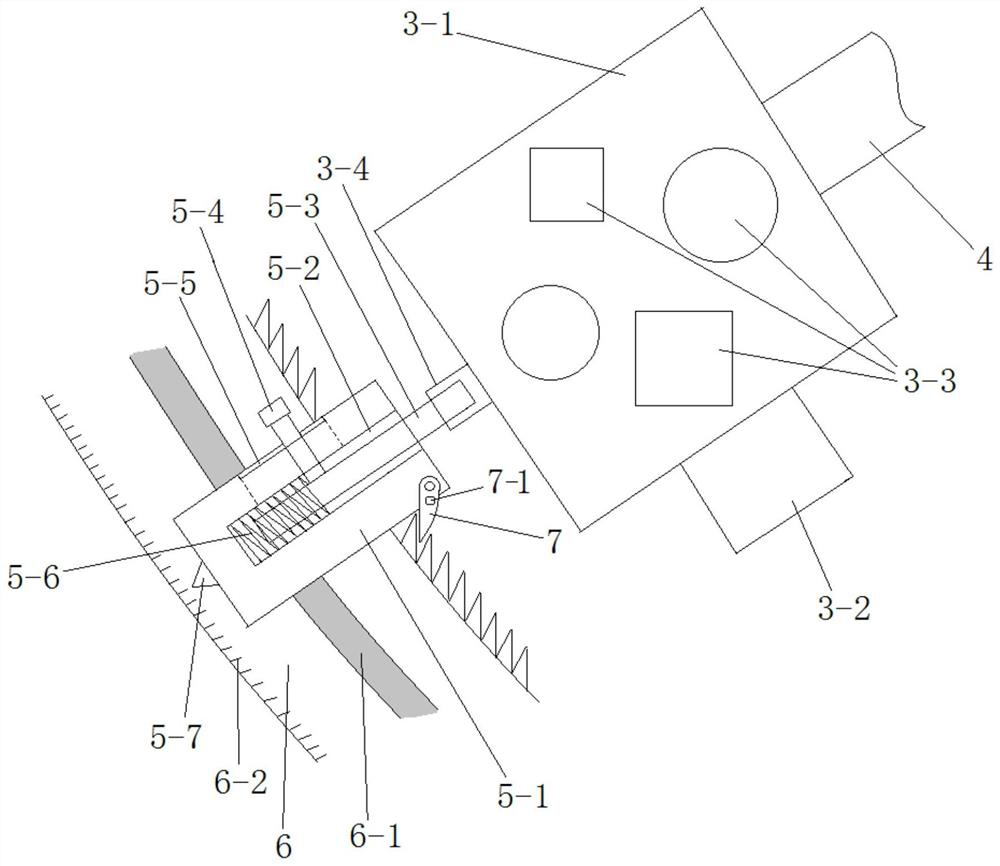

[0017] See eg figure 1 , the embodiment of the present invention provides a mechanical strength testing device, comprising a base 1, a frame body 2 is provided on the base 1, the frame body 2 is hinged with the upper end of the swing rod 4, and the lower end of the swing rod 4 is fixed with The impact hammer 3 is provided with an arc-shaped first ratchet 6 located on the same plane as the arc-shaped swing track 14 on the outside of the arc-shaped swing track 14 of the impact hammer 3 and at the same position as the center of the circle. The first ratchet 6 is fixed on the frame body 2, and the first ratchet 6 is slidably connected with a positioning device 5 for fixing the initial swing position of the impact hammer 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com