Uncoiling machine for waterproof coiled material

A waterproof coiled material, unwinding machine technology, applied in the direction of winding strips, casters, wheels, etc., can solve problems such as inconvenient adjustment work, coiled material falling on the ground, inconvenient adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

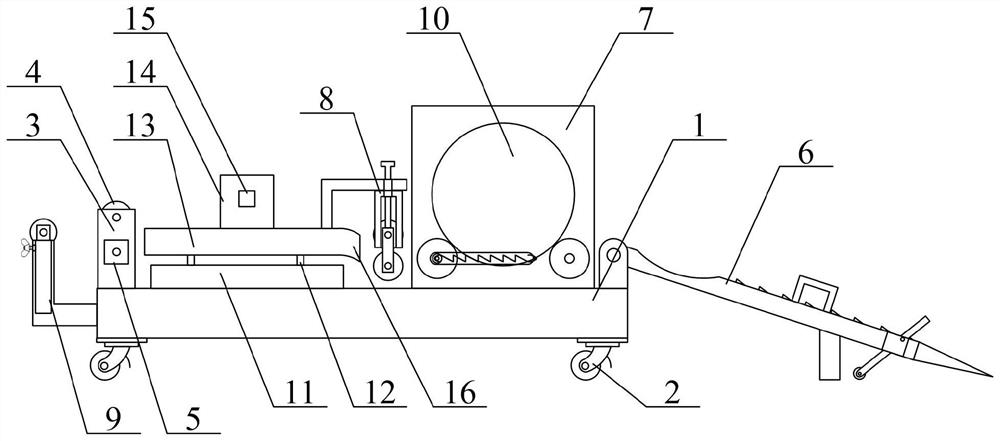

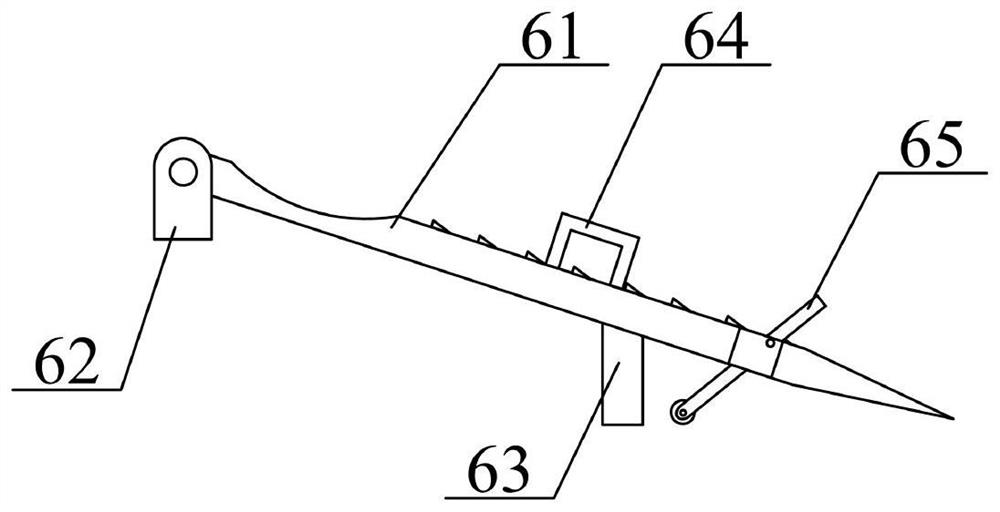

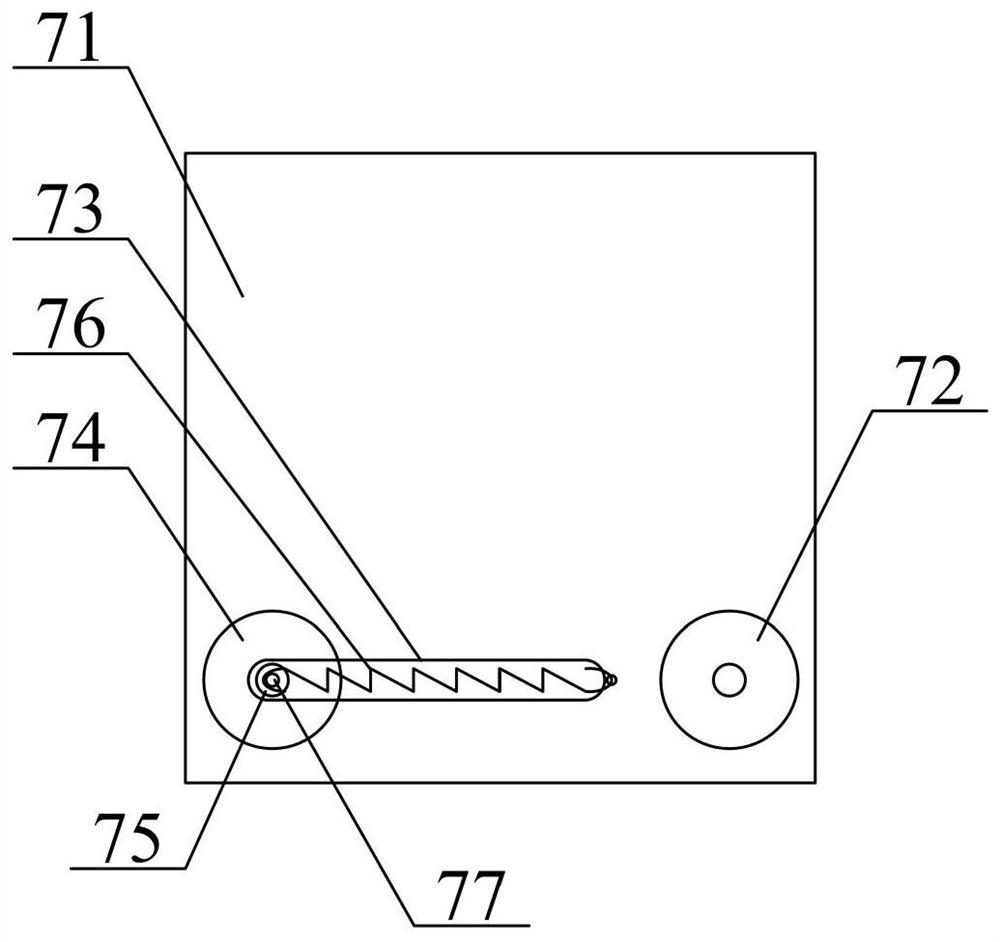

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an unwinding machine for waterproof coils includes a moving seat 1, a moving brake wheel 2, a first fixed frame 3, a conveying roller 4, a conveying motor 5, and a rotatable supporting feeding frame structure 6, which can clamp Hold reset support frame structure 7, adjustable guide frame structure 8, adjustable support roller structure 9, coil roll 10, connecting seat 11, first support rod 12, protective plate 13, control box 14, power switch 15 and arc Shaped plate 16, the moving brake wheels 2 are respectively bolted to the four corners of the lower end of the moving seat 1; the first fixed frame 3 is bolted to the left side of the upper end of the moving seat 1; Connected to the upper inner middle position and the lower inner middle position of the first fixed frame 3; the conveying motor 5 bolts are connected to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com