Convenient-to-maintain pesticide emulsifiable concentrate production shearing and emulsifying equipment

An emulsification equipment and emulsifiable concentrate technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of inconvenient adjustment, inconvenience, and easy precipitation of the emulsion to increase the mixing and stirring effect and prevent precipitation. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

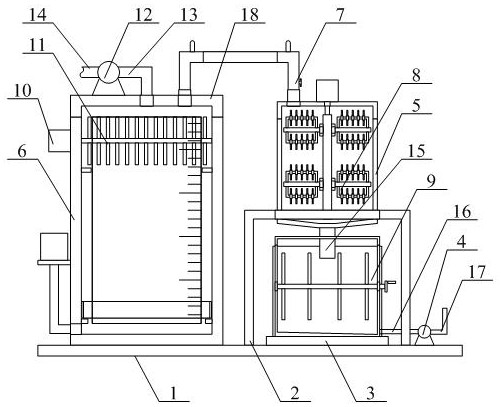

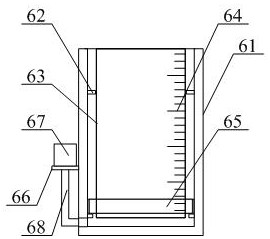

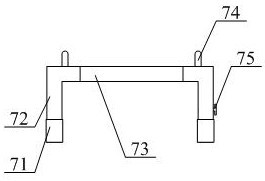

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a shear emulsification equipment for the production of pesticide emulsifiable concentrate that is easy to maintain includes a base 1, a fixed bracket 2, a support plate 3, a discharge pump 4, a mixing barrel 5, and a structure 6 that can observe and measure the pushing tank, and can observe and adjust the conveying Pipe structure 7, rotatable and fixed stirring rod structure 8, storable heat preservation stirring barrel structure 9, stirring motor 10, stirring rod 11, filling pump 12, feeding pipe 13, feeding connecting pipe 14, inserting pipe 15, suction Pipe 16, output pipe 17 and fixed cover 18, the fixed bracket 2 is bolted to the middle position on the upper right side of the base 1; the support plate 3 is bolted to the upper right side of the base 1 and arranged on the fixed bracket 2 The middle position of the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com