Corn miss-seeding reseeding device and control system

A technology of missed seeding and corn, applied in electrical program control, program control in sequence/logic controller, planter parts, etc., can solve problems such as missed seeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

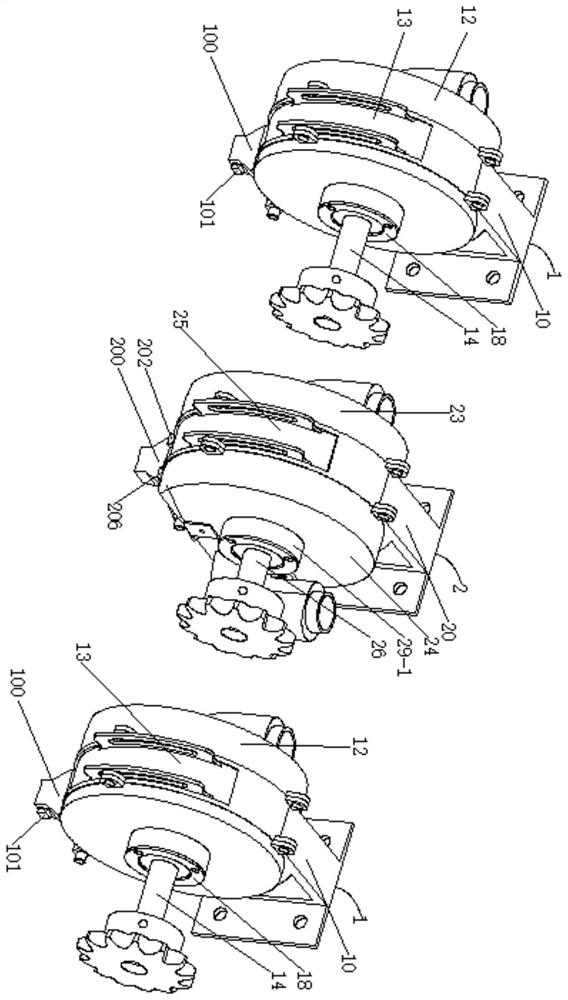

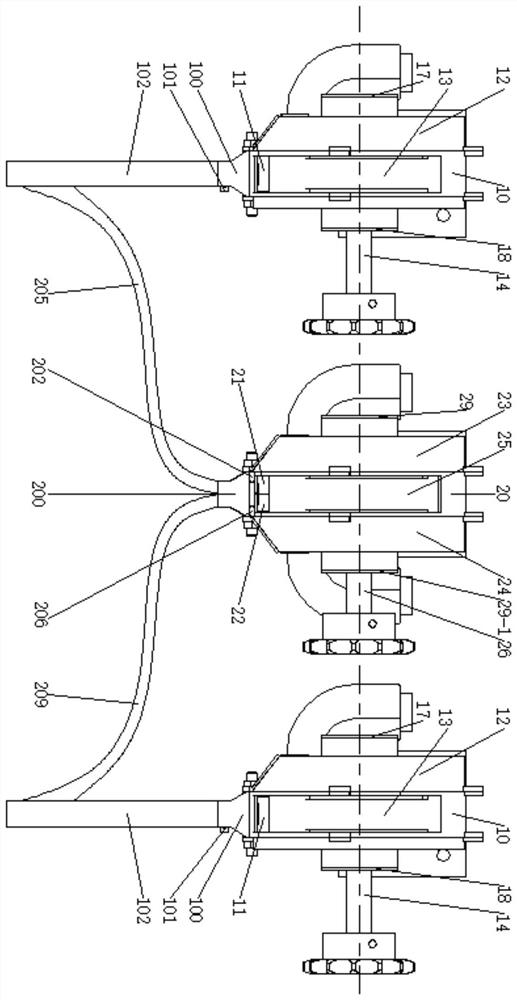

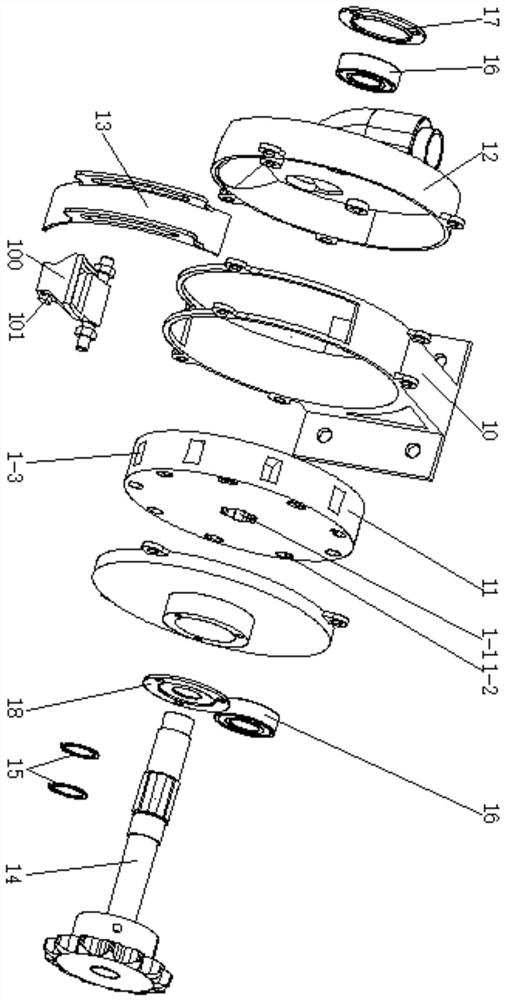

[0080] In the corn missed seed replenishing device, the lower end of the housing 10 of the seed metering device 1 is provided with a seed storage hopper 100, and the side of the seed storage hopper 100 is provided with an optical fiber sensor 101, so as to realize the seeding of the seed meter 1 Real-time monitoring provides real-time signals for missed seeding for the single-chip microcomputer; the lower end of the seed storage hopper 100 is connected with a blanking pipe 102 to ensure that the seeds fall accurately in the trench opened by the trencher and prevent the seeds from falling on the base soil on both sides , Causing seeding failure.

[0081] The second seed hopper 200 is provided at the lower end of the second seat shell 20, and the second seed hopper 200 is provided with a partition 201 in the middle. The second seed hopper 200 is divided into a left chamber 201-1 and a right chamber 201-2. A left rotating cylinder 202 is provided on the outer wall of the left chambe...

Embodiment 2

[0084] The control system of the corn missed seed replenishing device includes a single-chip microcomputer, a solenoid valve 1 and a solenoid valve 2, an optical fiber sensor 101 at the lower end of the seed metering device 1 on the left and an optical fiber sensor at the lower end of the seed metering device 1 on the right 101 are respectively connected to the input end of the single-chip microcomputer. The first solenoid valve and the second solenoid valve are connected to the output end of the single-chip computer. 206 is connected by the trachea.

[0085] First put the corn seeds into the first seed filling chamber cover 12 on both sides and the left seed filling chamber cover 23 and right seed filling chamber cover 24 in the middle, and then the seed metering devices 1 on both sides work, and the spindle 14 passes outside The spline and spline hole 1-1 drive the seed metering disk 11 to rotate, and the seeds in the first seed filling chamber cover 12 enter the U-shaped curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com