Bottom-fixed ADCP probe sink-float system, mounting method thereof and maintenance debugging method

A bottom-mounted and bottom-mounted technology, which is used in measurement devices, instruments, surveying and navigation, etc., can solve the problem that the installation, debugging and maintenance of bottom-mounted ADCP probes cannot be carried out, which affects the accuracy and precision of flow measurement data. Inconvenient installation, commissioning and maintenance, etc., to achieve the effect of convenient installation process, reliable control effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

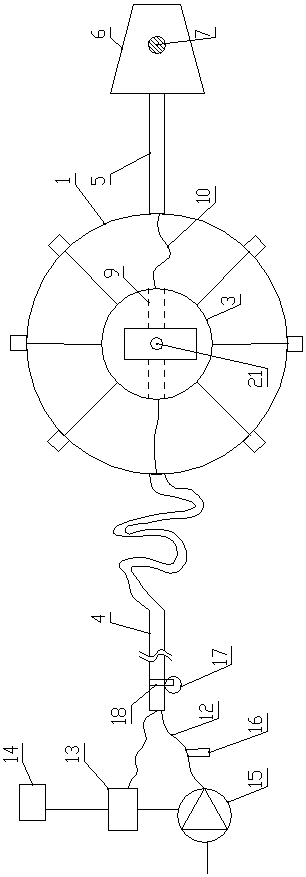

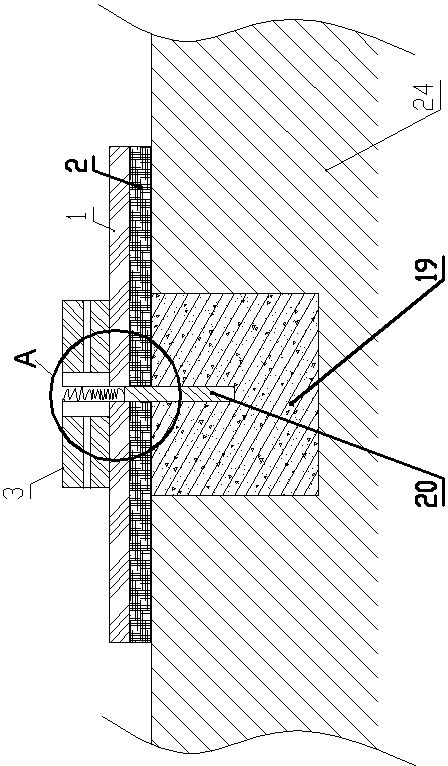

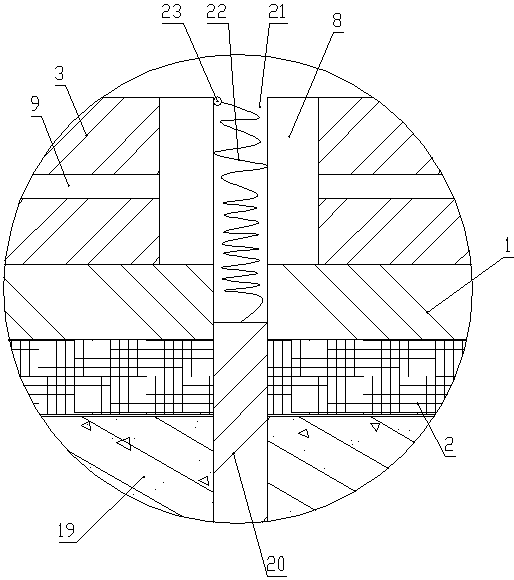

[0045] Such as Figure 1 to Figure 4 As shown, the sinking and floating system of the bottom-attached ADCP probe of the present invention includes a floating and sinking mechanism, a trapezoidal plate 6 and a control mechanism;

[0046]The floating and sinking mechanism includes a circular support plate 1 (the support plate 1 also plays the role of counterweight), the airbag 2 for controlling the floating and sinking is connected under the support plate 1, and the circular line summarizing plate 3 is fixedly connected upwards in the middle of the support plate 1 ; The outer edge of the support plate 1 is symmetrically provided with two connection points, and the connection point located on the right left is connected to the cable main pipe 4 connected with the control mechanism; the end of the cable main pipe 4 extends to the river bank, and the cable main pipe 4 All have elasticity, and the cable main pipe 4 adjacent to the support plate 1 has a redundant length; the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com