Facing stone cage net bag bump-free dump filling construction method

A construction method and technology of gabion nets, applied in infrastructure engineering, construction, etc., can solve the problem of lack of anti-corrosion coating protection function, difficulty in arranging double-hook lifting equipment, and inability to ensure that the gabion net bag structure is close to the steel cylinder revetment One side of the structure and other problems can be achieved to reduce the underwater unhooking operation, reduce the number of use, and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] As shown in the accompanying drawings, the face protection gabion net bag of the present invention has no bumping and throwing filling construction method, comprising the following steps:

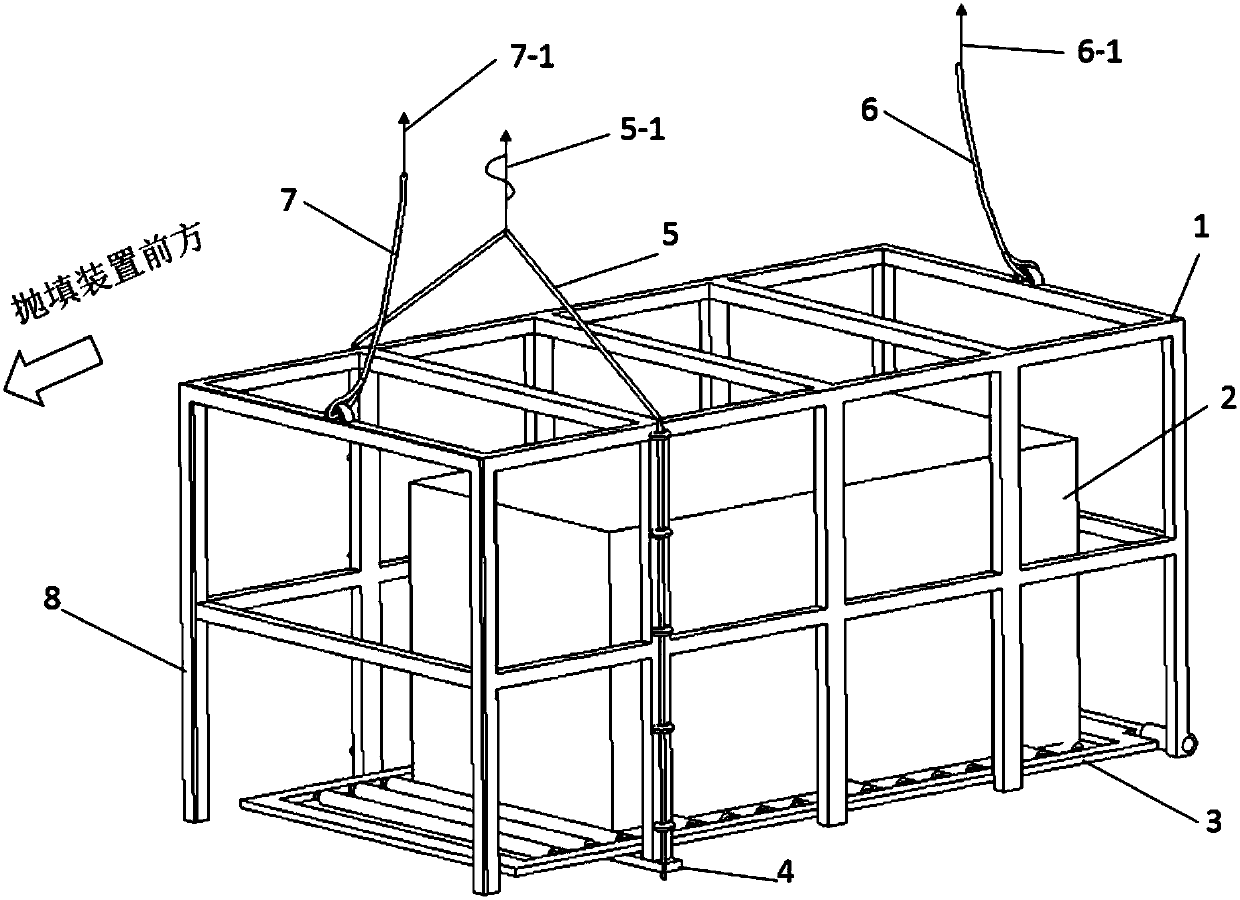

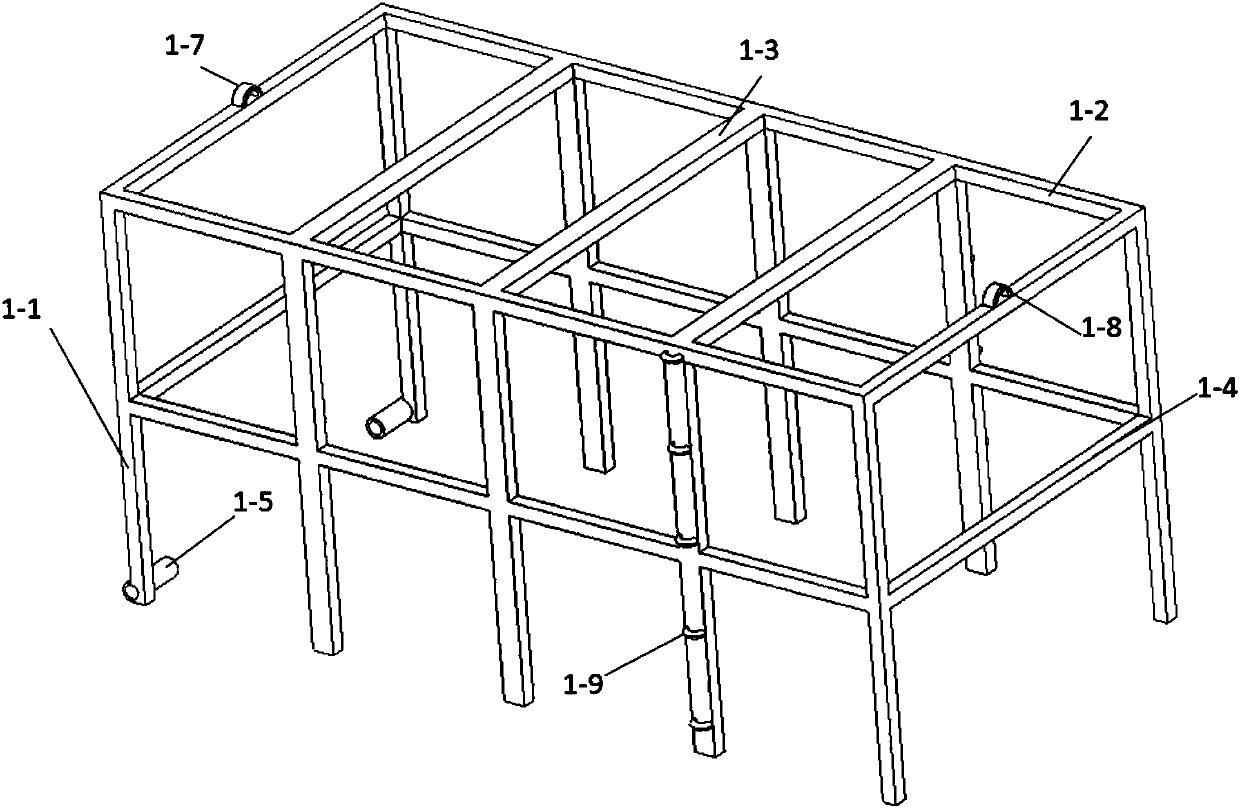

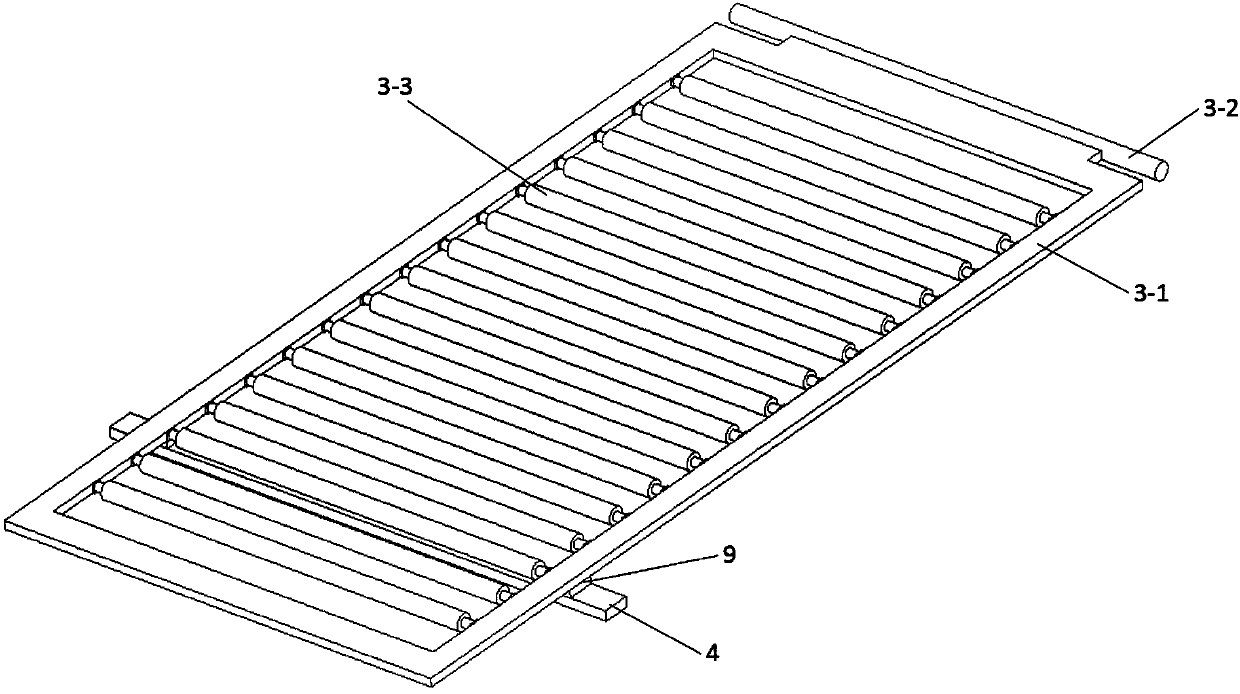

[0034] (1) Prepare gabion net throwing and filling device, described gabion net throwing and filling device comprises the upper part frame body 1 that the bottom is open and the cross section is rectangular, and described upper part frame body comprises two row racks arranged in parallel and spaced left and right The vertical support column of the frame body, each vertical support column of the frame body includes a plurality of vertical support columns 1-1 of the frame body arranged in parallel and at intervals, and the top and middle between the vertical support columns of the adjacent two frame bodies The top connecting beam 1-2 and the middle co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com