Fire fighting robot fire monitor control method based on fire source positioning and recognition

A fire-fighting robot, positioning and identification technology, applied in fire rescue and other directions, can solve problems such as low efficiency, insufficient environmental information, and long adjustment time for unmanned fire-fighting robot fire monitor control, so as to improve efficiency, suppress fire, and make up for work efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

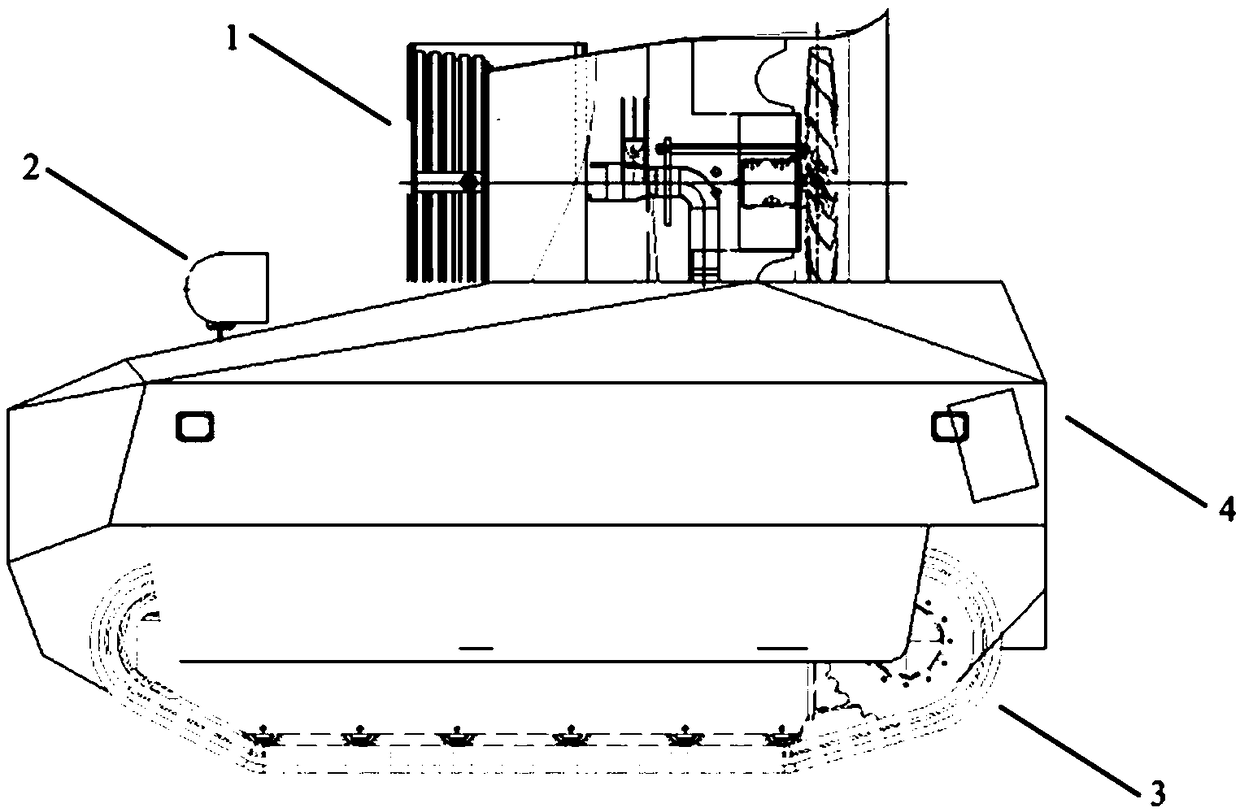

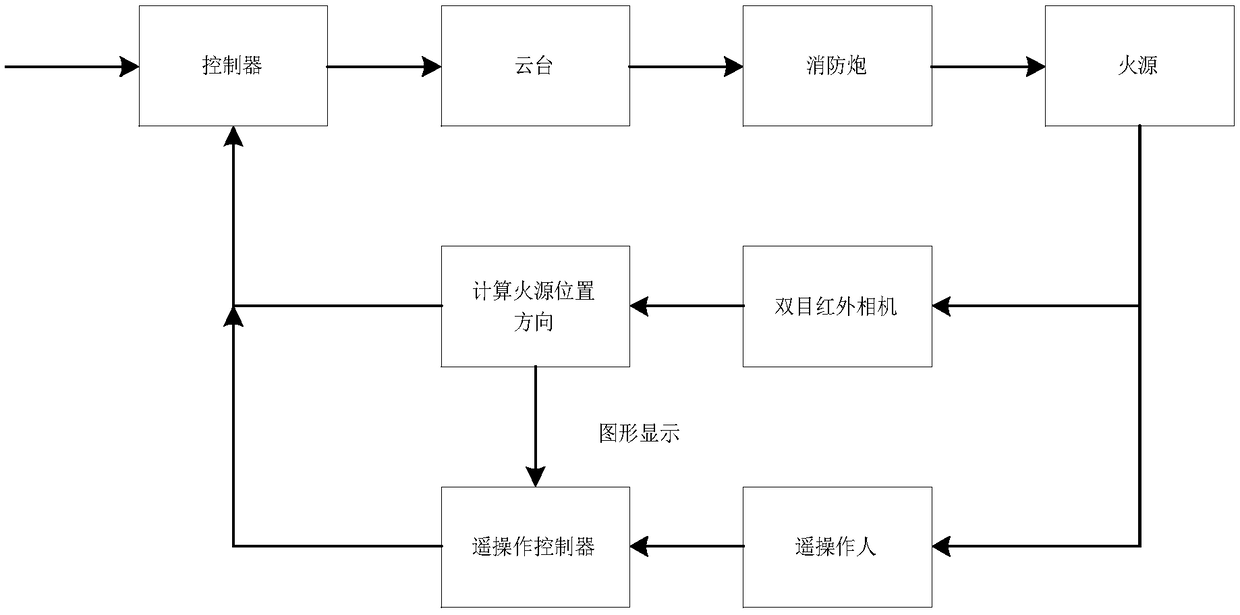

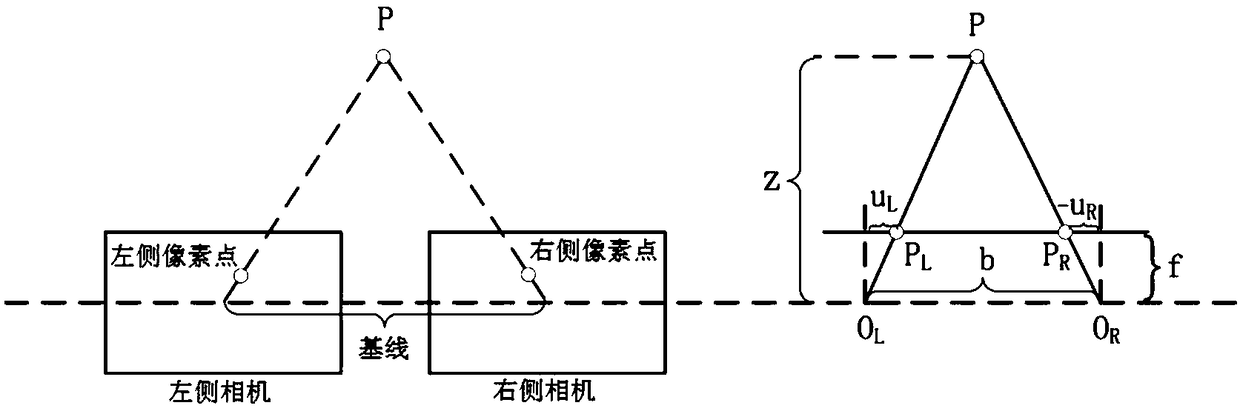

[0032] The present invention has designed a kind of fire-fighting robot fire cannon control method based on fire source location identification, and the structure of fire-fighting robot in the present embodiment is as follows figure 1 As shown, the fire-fighting robot includes a fire-fighting robot body 4, a fire cannon 1 with a two-axis pan-tilt, a binocular infrared camera 2, and a fire-fighting robot crawler 3. In order to realize the farthest range of fire source positioning, the binocular infrared camera 2 can Including two left and right infrared cameras symmetrically arranged, respectively placed on both sides of the fire robot body; the two-axis pan-tilt is set on the fire robot body, and connected to the fire monitor, which has great uncertainty for the operator to adjust the fire monitor Due to defects such as flexibility and long adjustment time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com