A low-temperature S-type aerosol fire extinguishing agent

An aerosol and fire extinguishing agent technology, applied in the direction of fire prevention equipment, etc., can solve problems such as corrosion of equipment and documents, impact of fire extinguishing efficiency, high combustion temperature, etc., achieve the effect of reducing corrosion performance, protecting precision equipment and documents, and reducing secondary combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

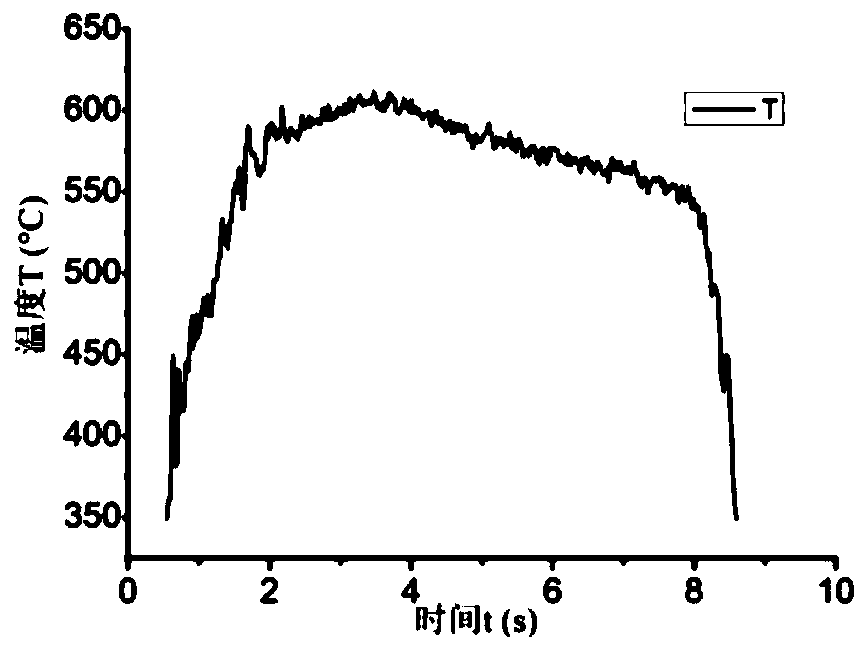

Image

Examples

Embodiment 1

[0018] Each component is weighed according to the following parts by mass:

[0019] Strontium nitrate 45

[0020] Potassium nitrate 20

[0021] Dicyandiamide 23

[0022] Phenolic resin 3

[0024] Hexamethylenetetramine 4

[0026] Weigh 5g formula at 0.15m 3 Fire extinguishing experiment was carried out, the fire extinguishing time was 39s, and the fire extinguishing efficiency was 33.33g / m 3 . The corrosion test was carried out on the combustion products, the weight loss rate of the copper sheet was 0.354%, the weight loss rate of the aluminum sheet was 0.859%, and the insulation test result was 120MΩ.

Embodiment 2

[0028] Each component is weighed according to the following parts by mass:

[0029] Strontium nitrate 43

[0030] Potassium nitrate 22

[0031] Dicyandiamide 26

[0032] Phenolic resin 5

[0033] Potassium oxalate 4

[0034] Hexamethylenetetramine 2

[0036] Weigh 5g formula at 0.15m 3 Fire extinguishing experiment was carried out, the fire extinguishing time was 41s, and the fire extinguishing efficiency was 33.33g / m 3 . The corrosion test was carried out on the combustion products, the weight loss rate of the copper sheet was 0.209%, the weight loss rate of the aluminum sheet was 0.41%, and the insulation test result was 120MΩ.

Embodiment 3

[0038] Each component is weighed according to the following parts by mass:

[0039] Strontium nitrate 55

[0040] Potassium nitrate 30

[0041] Dicyandiamide 20

[0042] Phenolic resin 7

[0043] Potassium oxalate 5

[0044] Hexamethylenetetramine 3

[0045] Magnesium powder 1

[0046] Weigh 5g formula at 0.15m 3 The fire extinguishing experiment was carried out, the fire extinguishing time was 34s, and the fire extinguishing efficiency was 33.33g / m 3 . The corrosion test was carried out on the combustion products, the weight loss rate of the copper sheet was 0.241%, the weight loss rate of the aluminum sheet was 0.422%, and the insulation test result was 122MΩ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com