Smart factory firefighting inspection system

An inspection system and factory technology, applied in fire rescue and other directions, can solve problems such as increased loss, foreign object collision, and prolong fire extinguishing time, and achieve the effect of facilitating later maintenance, improving response ability, and reducing fire extinguishing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

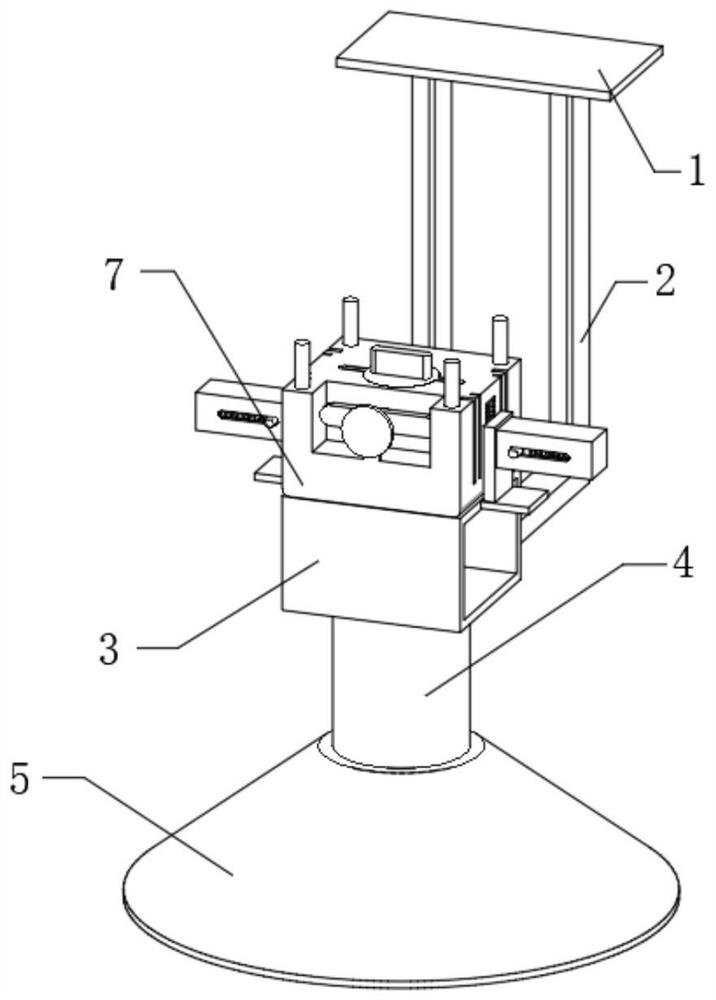

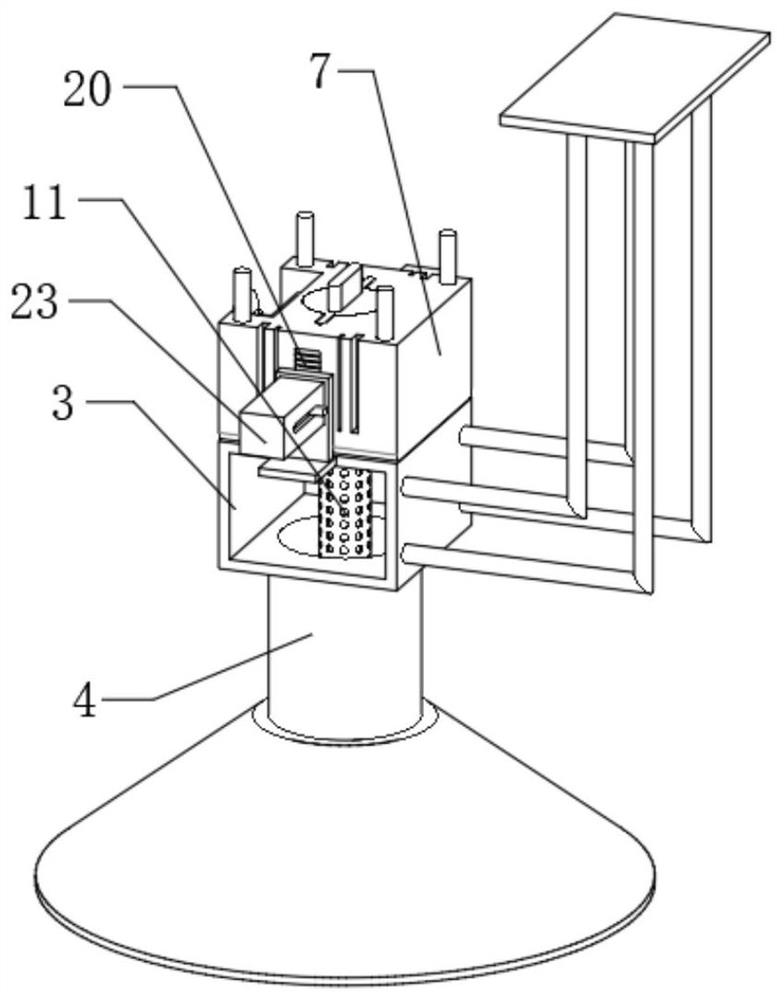

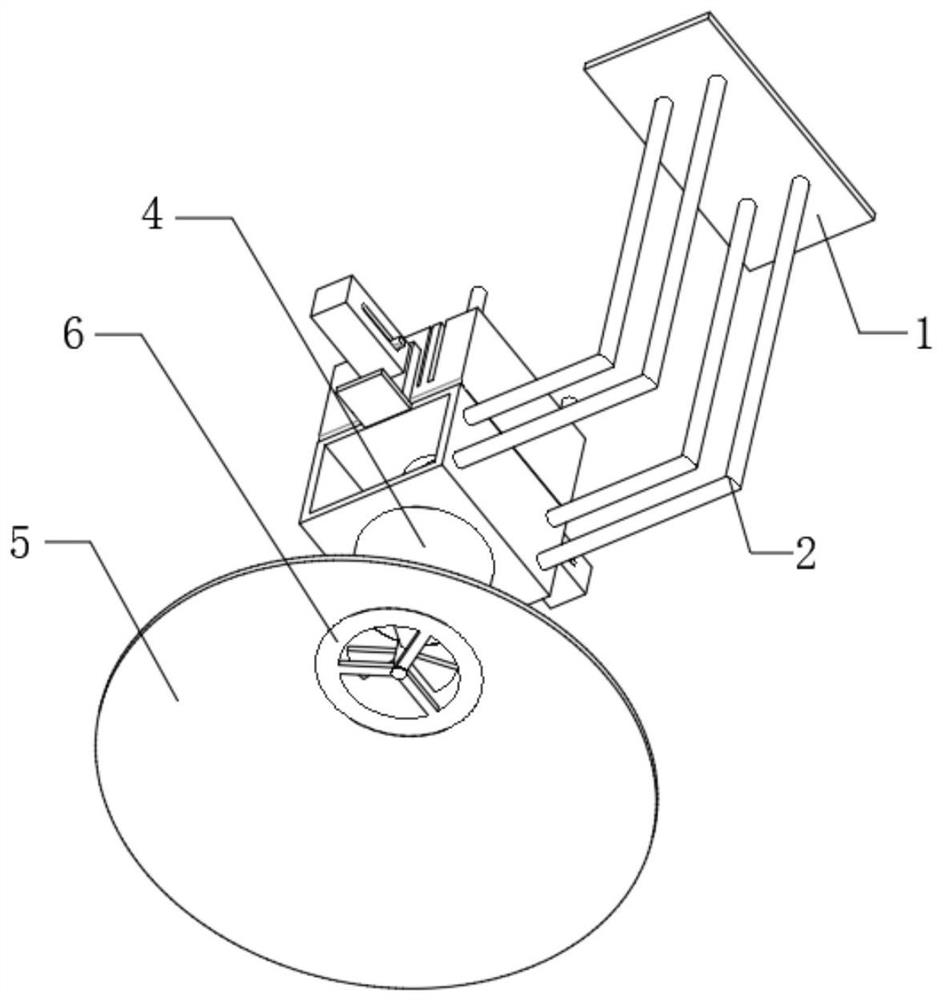

[0036] The embodiment of the present invention discloses a smart factory fire inspection system, such as Figure 1-10 shown, including:

[0037] The overall support plate 1 of the device, the overall support plate 1 of the device is fixedly connected to the ceiling by bolts, the bottom of the overall support plate 1 of the device is fixedly connected with a support fixed rod 2, and the end of the support fixed rod 2 away from the overall support plate 1 of the device is fixedly connected with a ventilation The top of the square pipe 3 and the ventilating square pipe 3 are fixedly installed with the inspection system sensor mounting seat 7, and the top of the inspection system sensor mounting seat 7 is provided with a circular clamping groove 10;

[0038] Vertical round pipe 4, vertical round pipe 4 is fixedly connected to the bottom of ventilating square pipe 3, and the bottom of vertical round pipe 4 is fixedly connected with horn collecting cover 5;

[0039] The air flow fa...

Embodiment 2

[0052] The embodiment of the present invention discloses a smart factory fire inspection system, such as Figure 1-10 shown, including:

[0053] The overall support plate 1 of the device, the overall support plate 1 of the device is fixedly connected to the ceiling by bolts, the bottom of the overall support plate 1 of the device is fixedly connected with a support fixed rod 2, and the end of the support fixed rod 2 away from the overall support plate 1 of the device is fixedly connected with a ventilation The top of the square pipe 3 and the ventilating square pipe 3 are fixedly installed with the inspection system sensor mounting seat 7, and the top of the inspection system sensor mounting seat 7 is provided with a circular clamping groove 10;

[0054] Vertical round pipe 4, vertical round pipe 4 is fixedly connected to the bottom of ventilating square pipe 3, and the bottom of vertical round pipe 4 is fixedly connected with horn collecting cover 5;

[0055] The air flow fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com