Electrical component test frame and operation process thereof

A technology of electrical components and test racks, which is applied to the parts of electrical measuring instruments, instruments, and measuring electronics. It can solve problems such as damage, bumping of electrical components, and inability of electrical components to fall accurately on the test box, so as to reduce the possibility of Sex, reduce the effect of left and right shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-6 The application is described in further detail.

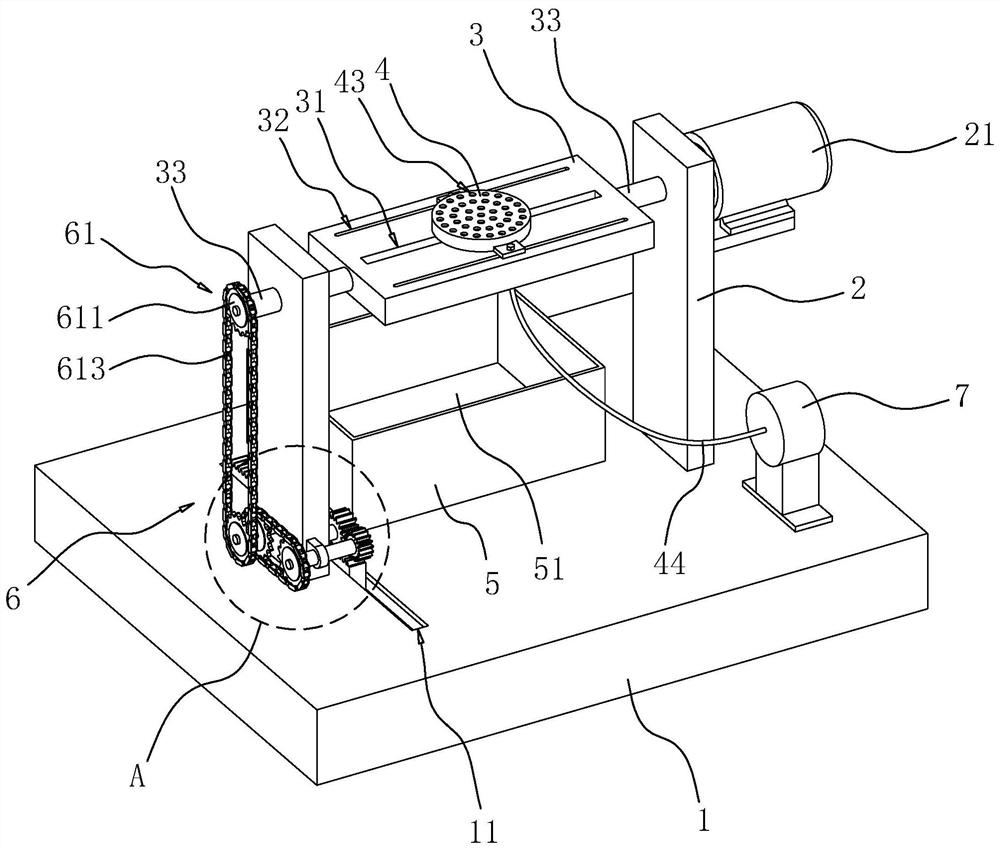

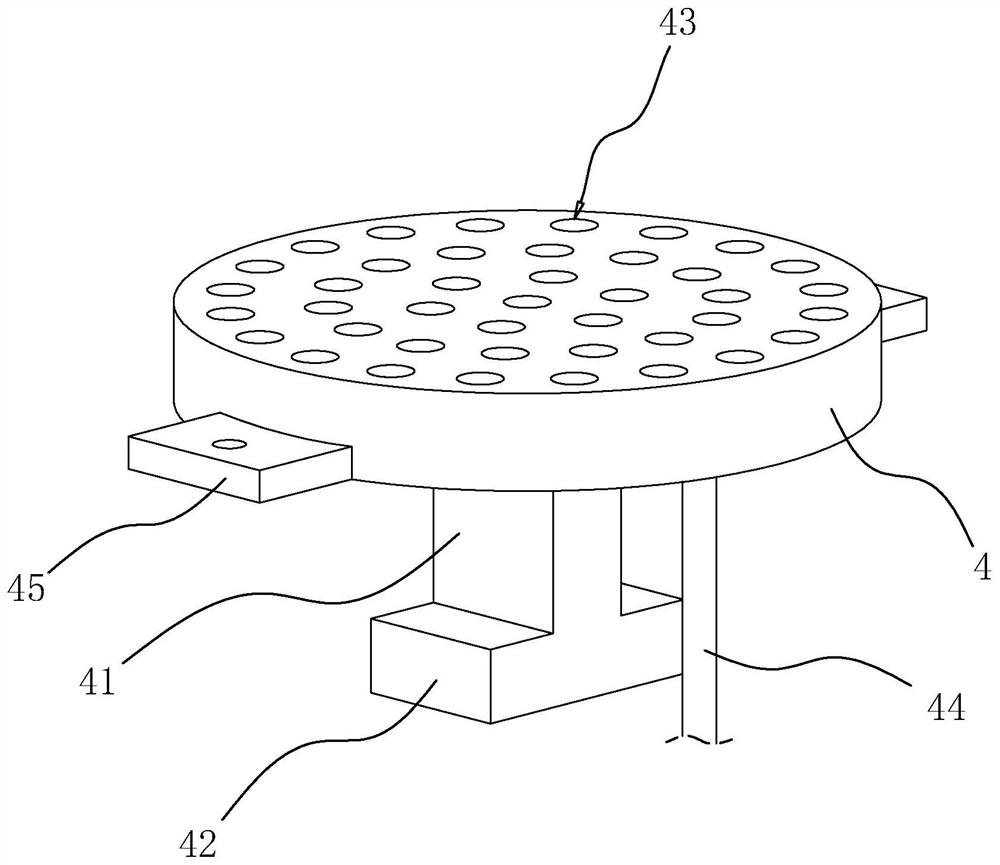

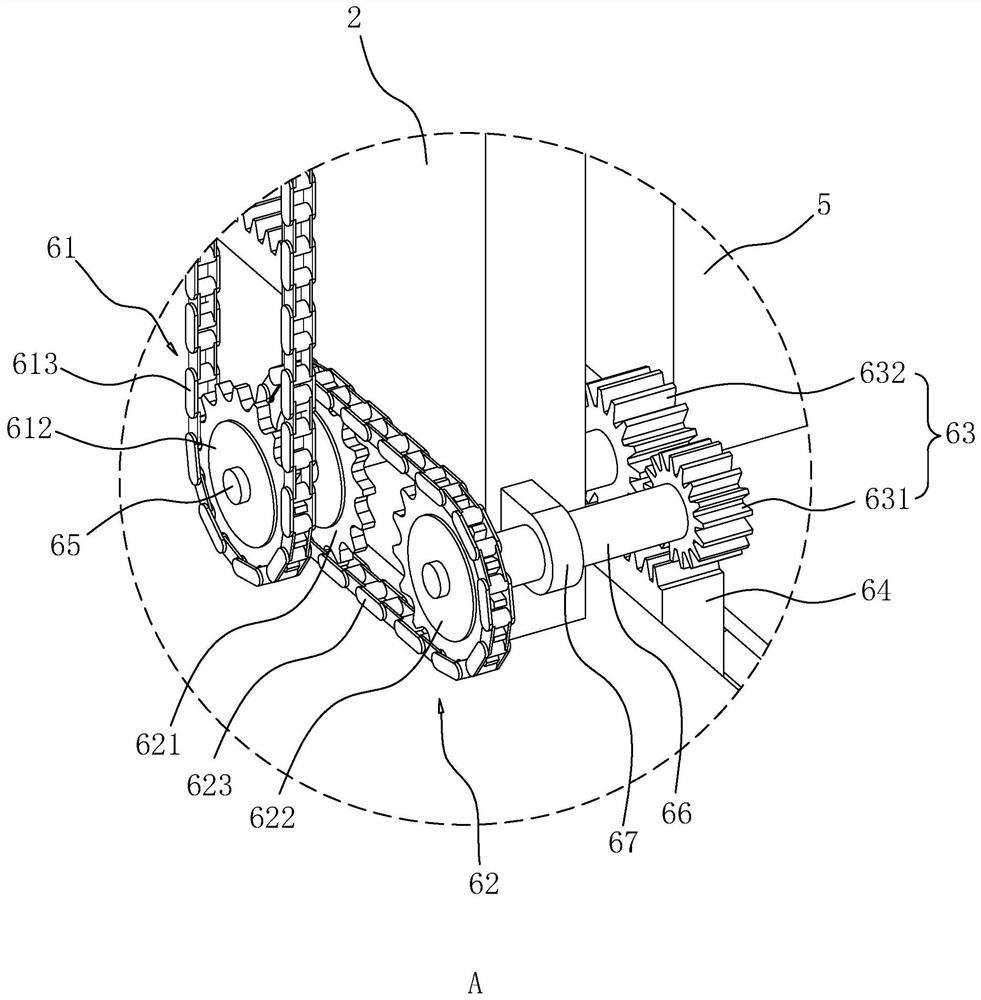

[0047] The embodiment of the present application discloses an electrical component testing rack. refer to figure 1 , the test frame includes a test seat 1 placed horizontally, two support plates 2 arranged in parallel are fixedly connected to the test seat 1, and a horizontal test bottom plate 3 is provided for rotation between the two support plates 2 at a position close to the top, On the top of the test base plate 3, a test disc 4 for placing electrical components is slidably installed. A test box 5 is slidably installed between two support plates 2 on the test seat 1, and the sliding direction of the test box 5 is perpendicular to the connection direction of the two support plates 2. The transmission mechanism 6 for the test box 5 to slide.

[0048] refer to figure 1 with figure 2 , the upper surface of the test base plate 3 is provided with a sliding groove 31 penetrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com