Electric pay-off rack

A pay-off frame and electric technology, applied in the direction of cable laying equipment, etc., can solve the problems of affecting economic and social benefits, delaying project progress, and long construction period, so as to achieve a solid overall structure, reduce labor intensity, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

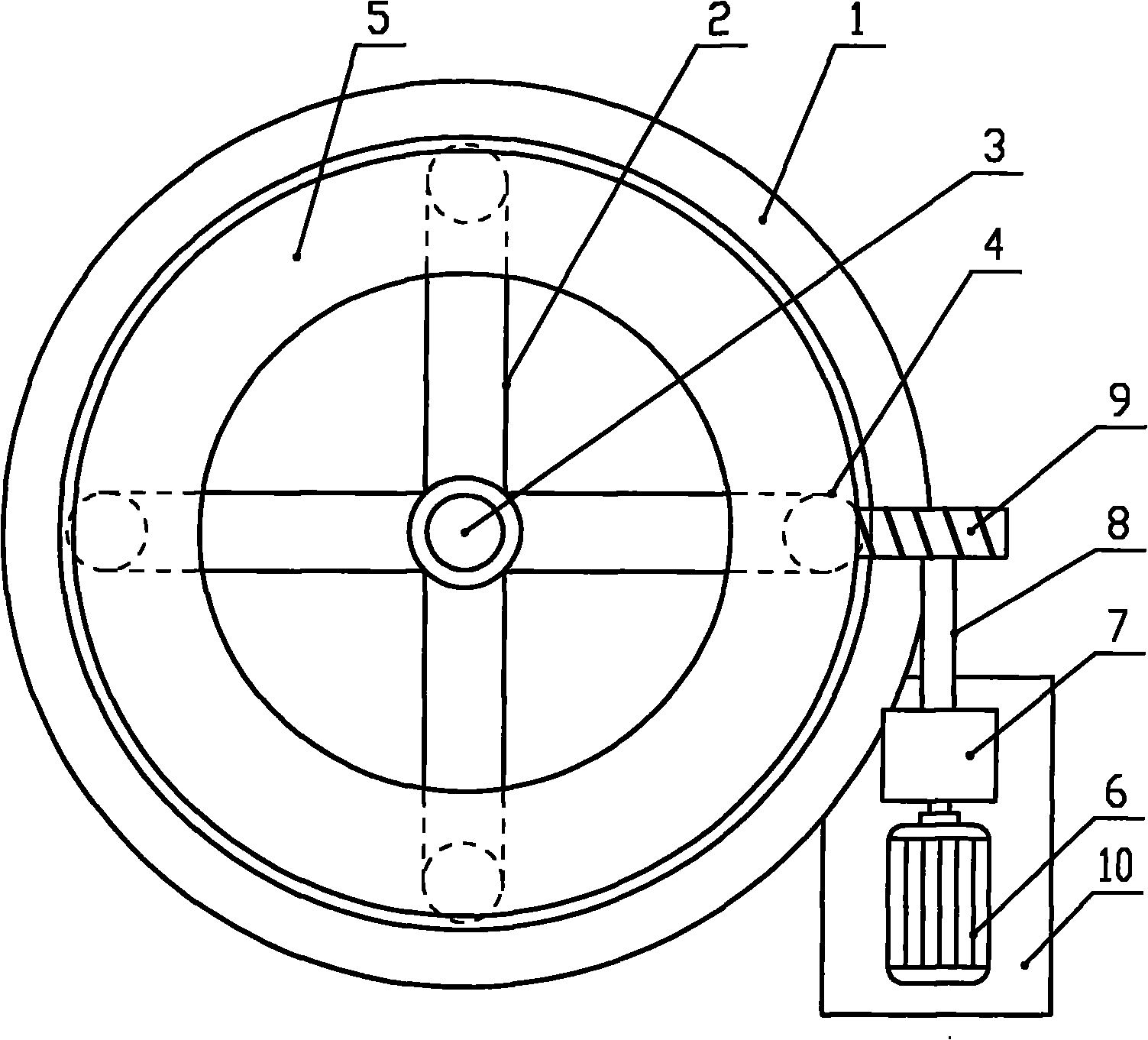

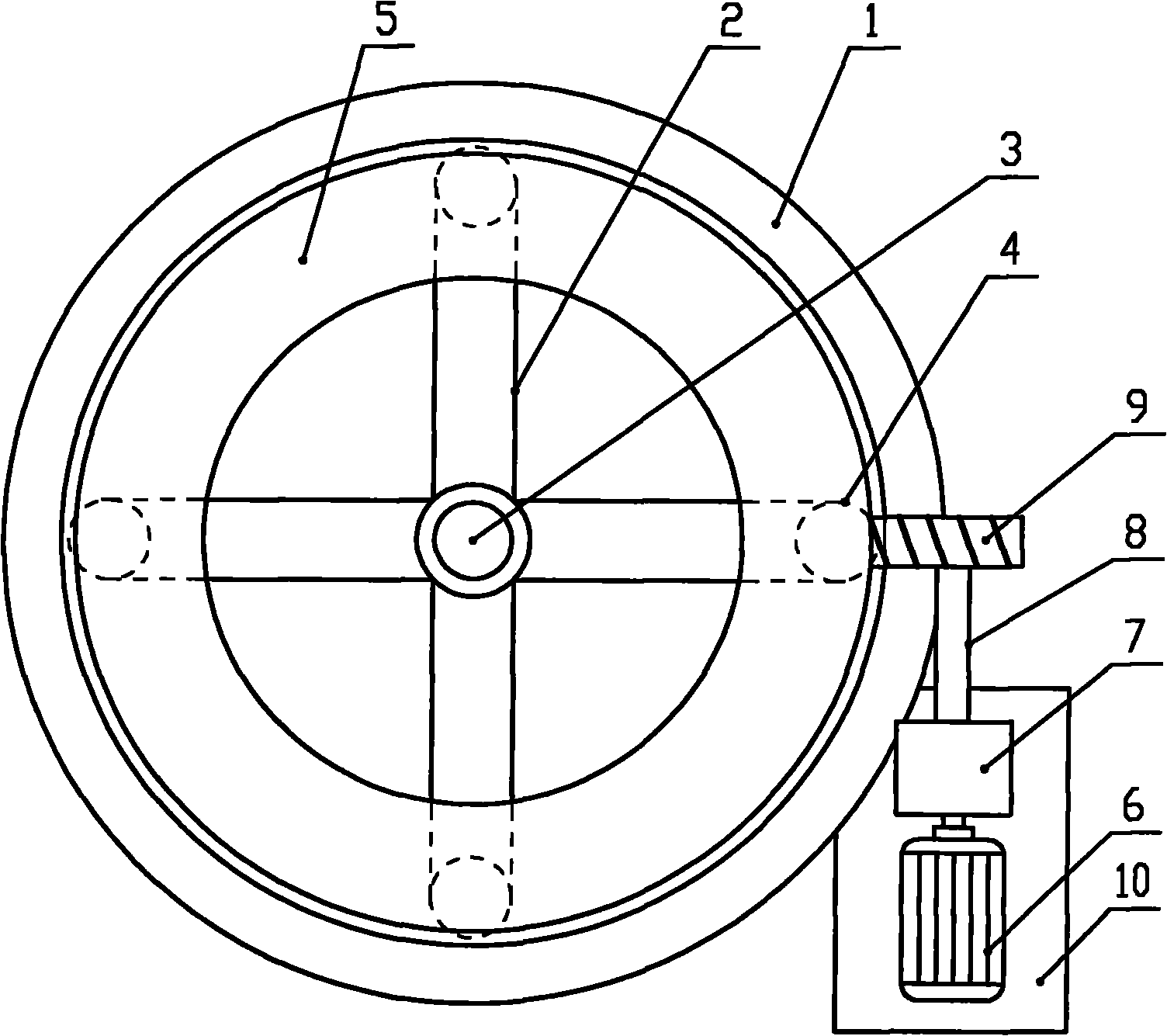

[0015] Such as figure 1 As shown, the electric pay-off stand of the present invention includes a base plate 1 and a horizontal rotation device, the horizontal rotation device is arranged on the base plate 1 and connected in rotation with the base plate 1, and the horizontal rotation device is connected with a power drive device. The horizontal rotation device includes a support frame 2, the center of the support frame 2 is provided with a main shaft 3 vertically fixedly connected to the base plate 1, the support frame 2 is connected to the main shaft 3 in rotation, and the lower part of the support frame 2 is evenly equipped with four shafts with the axis of the main shaft 3 as the central axis. The roller 4 and the upper part of the support frame 2 are horizontally provided with a support plate 5 with the axis of the main shaft 3 as the central axis, and the outer circumference of the support plate 5 is a helical tooth structure. The power drive device includes a motor 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com