Instant-heating high-pressure extruding and making type coffee machine

A coffee machine, hot high pressure technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of reducing the brewing efficiency, affecting the coffee effect, and slow heating speed of the coffee machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

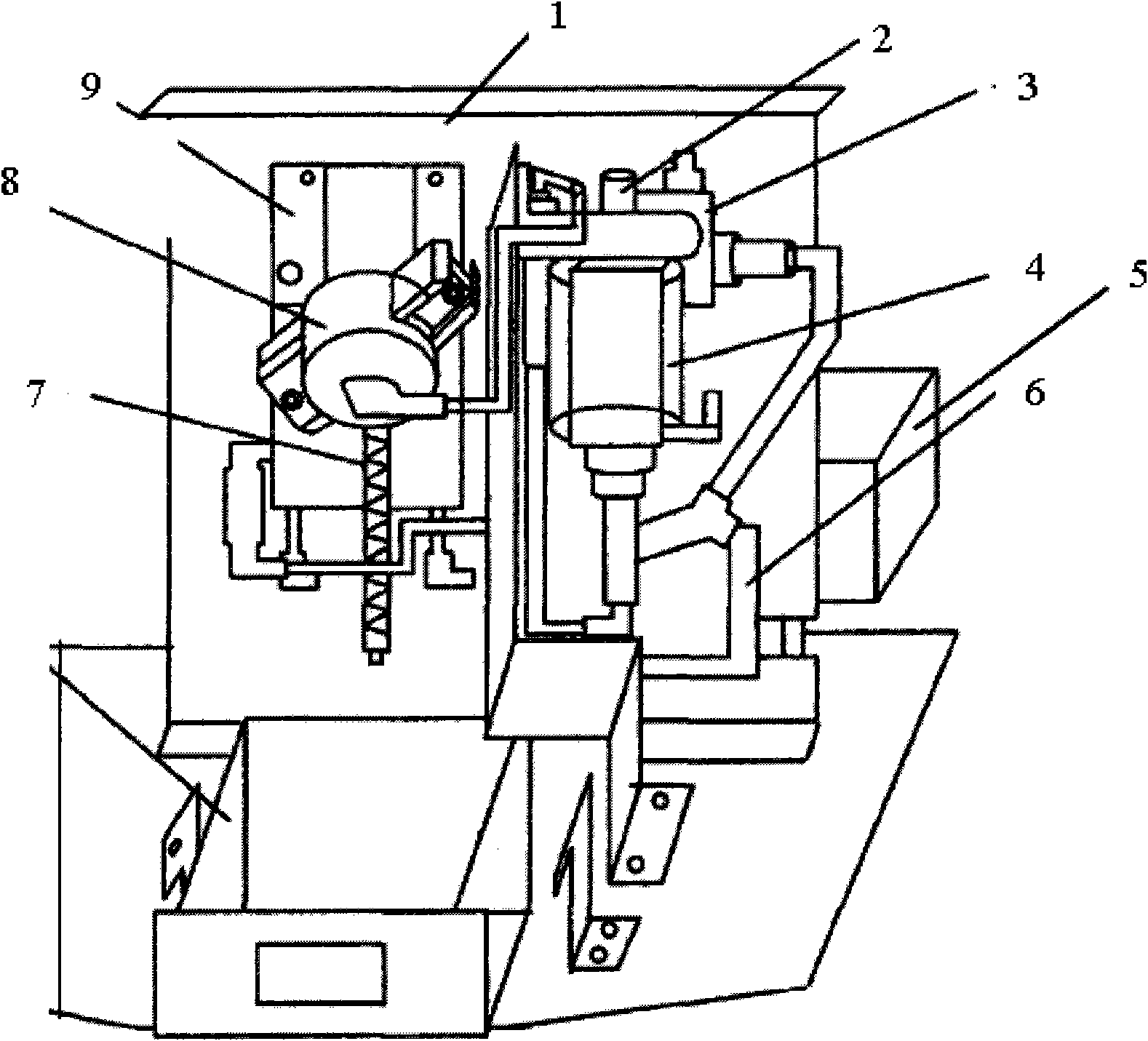

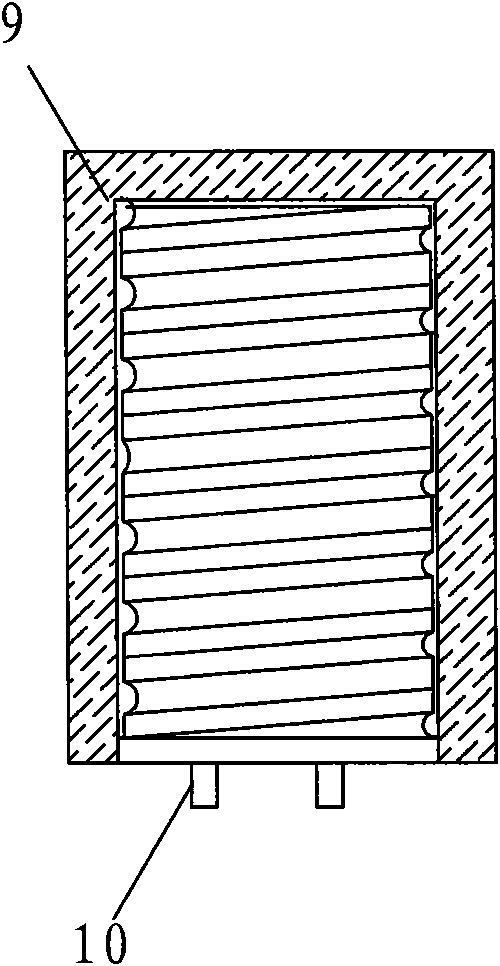

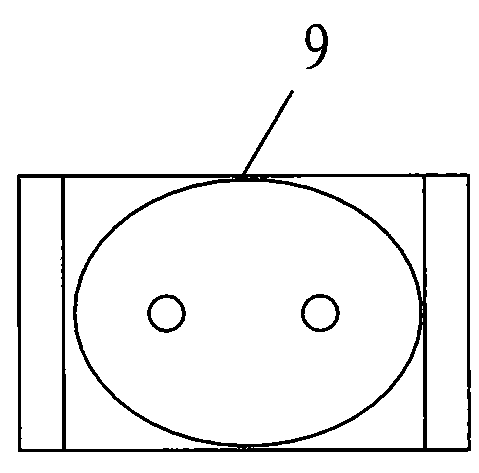

[0014] figure 1 , Figure 5 with Image 6 An instant hot and high-pressure squeeze coffee machine is shown, mainly comprising: a support block 1 arranged inside, a water tank 5 is provided on one side of the support block 1, and a water pump 4 is provided on the other side, and the water tank 5 and the water pump 4 are pumped The water pipe 2 is connected, and a water outlet pipe of the water pump 4 is connected to a boiler 9, and a cake press 8 is installed at a corresponding position on the front side of the boiler 9, and a coffee cake 11 is installed inside the cake press 8, and the cake press 8 compresses the coffee The cake 11 is tightly pressed inside, and a branched water pipe from a water outlet pipe of the water pump 4 is connected to a solenoid valve 3, and the solenoid valve 3 is connected to the rear end of the cake press 8, and a coffee outlet pipe 7 is connected to the bottom of the cake press 8. And the lower end of electromagnetic valve 3 is provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com