Flexible deformation combined injection molding die for serialized products

An injection mold and combined technology, which is applied in the field of molds in mechanical engineering, can solve problems such as delaying the time for products to occupy the market, increasing product costs, and reducing production efficiency, so as to save quantity, improve production efficiency, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

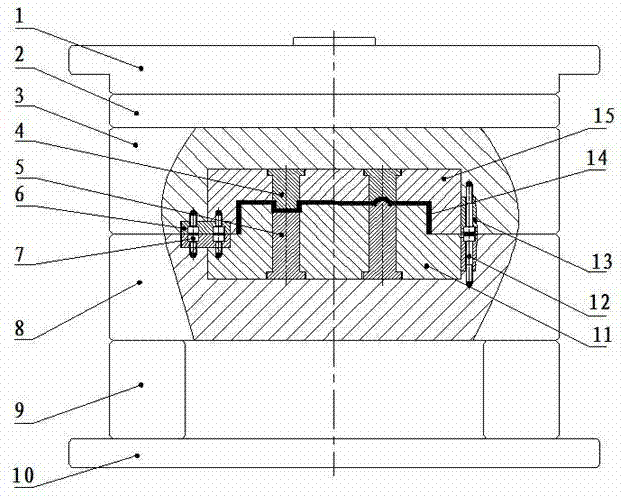

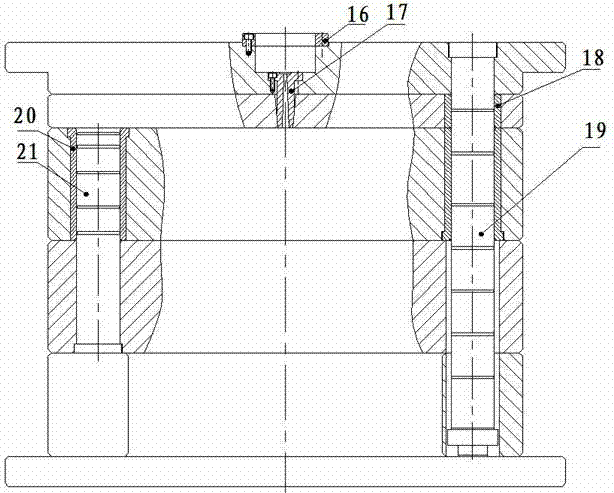

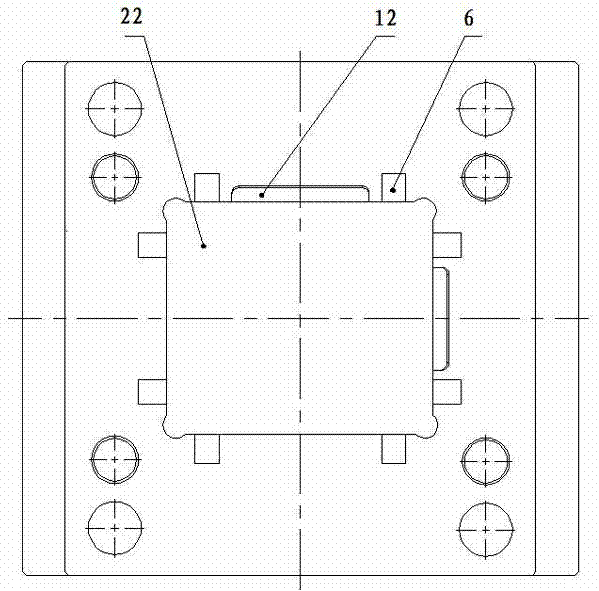

[0027] The specific structure and implementation of the present invention will be further described below through examples and with reference to the accompanying drawings.

[0028] Depend on figure 1 As shown, the flexible deformation combined injection mold for serialized products of the present invention: consists of an upper mold part and a lower mold part, and the upper mold part includes an upper mold base 1, an intermediate plate 2, a female template 3, an interchangeable female mold 15, Quick-change female mold insert 4, ramp 13, positioning ring 16, sprue sleeve 17, etc.; the lower mold part includes lower mold base 10, feet 9, male template 8, interchangeable male mold 11, quick-change Male die insert 5, ramp 13 etc.

[0029] The installation process of the upper mold part: first install the upper mold base 1 of the universal mold base on the fixed template of the injection machine, and connect the middle plate 2, the female template 3 and the upper mold base 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com