Detection-type locomotive lifting jack support head with weighing function

A technology of crane and head support, applied in the direction of rescue cranes, etc., can solve the problems of inconvenient adjustment, load change, and original position change, and achieve the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

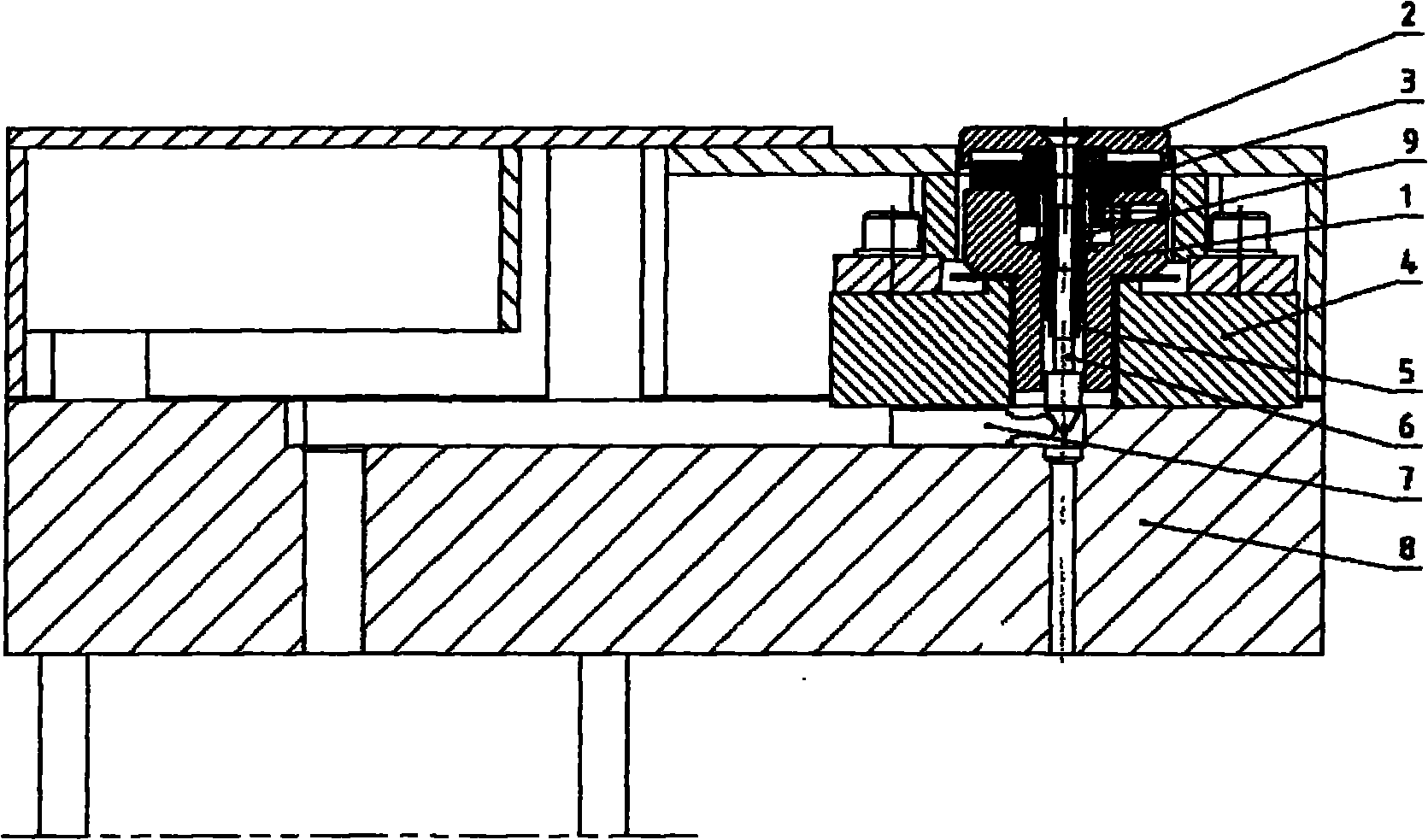

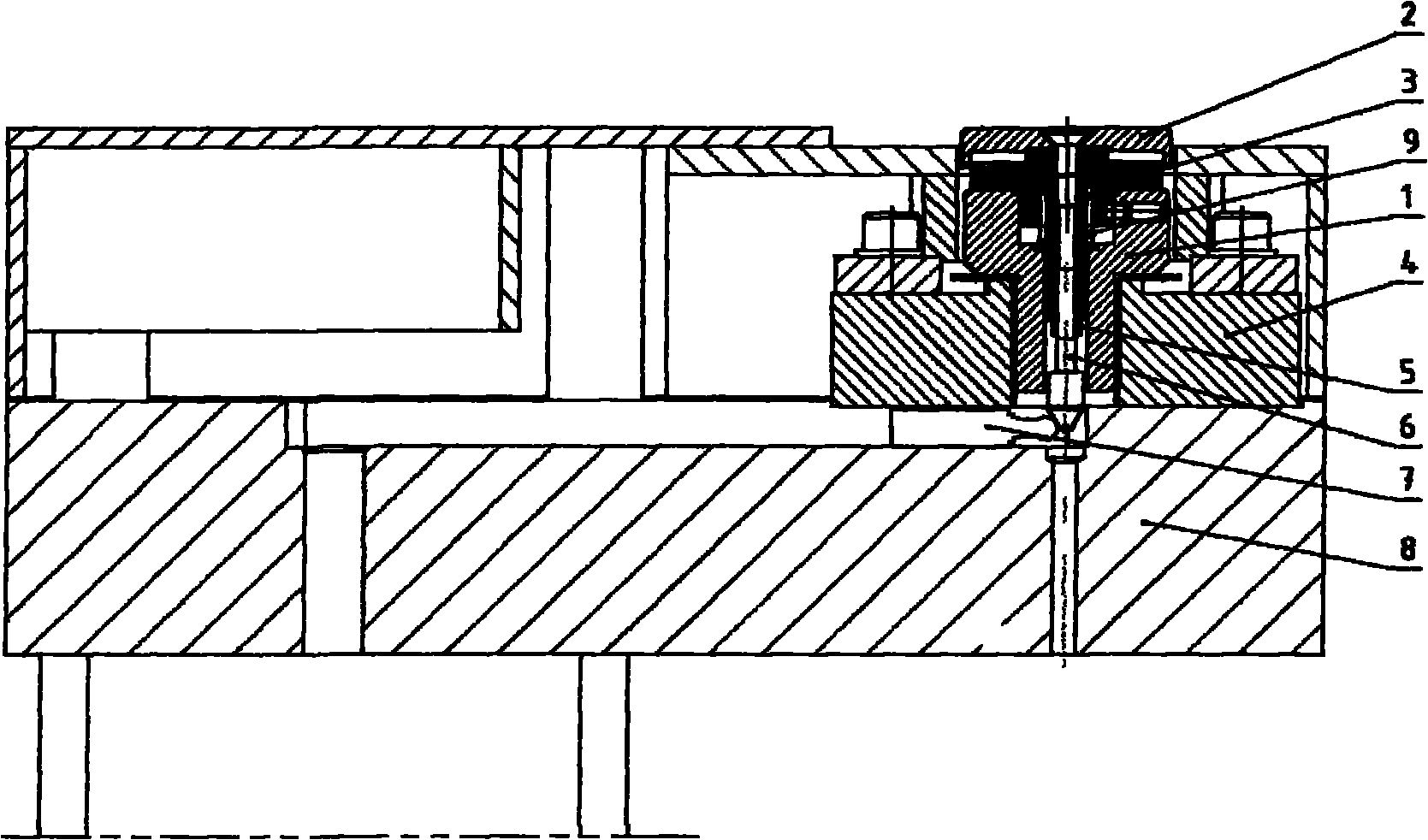

[0014] A probe-type truck crane supporting head with a weighing function, comprising a supporting head body 8 and a detection bearing device arranged on the supporting head body 8. The detection bearing device includes a connecting block 1, a pressure bearing plate 2, and a spring Support plate 3, spring, ejector rod 6, load detection limit switch 7, and load cell 4. The load cell 4 is installed on the head body 8, the connecting block 1 is installed on the load cell 4, and the upper part of the connecting block 1 is The bearing plate 2, the bearing plate 2 and the lower spring support plate 3 are connected. A spring is installed between the spring support plate 3 and the head body 8. The lower part of the bearing plate 2 is connected with the ejector rod 6 through threads, and the load detection limit The switch 7 is installed on the side of the ejector rod 6. After the bearing plate 2 is loaded, the springs of the bearing plate 2 and the head body 8 are compressed, the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com