High differential pressure resistance-type wind turbine

A wind turbine and resistance-type technology, applied in the field of wind energy applications, can solve problems such as low energy conversion efficiency and large rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

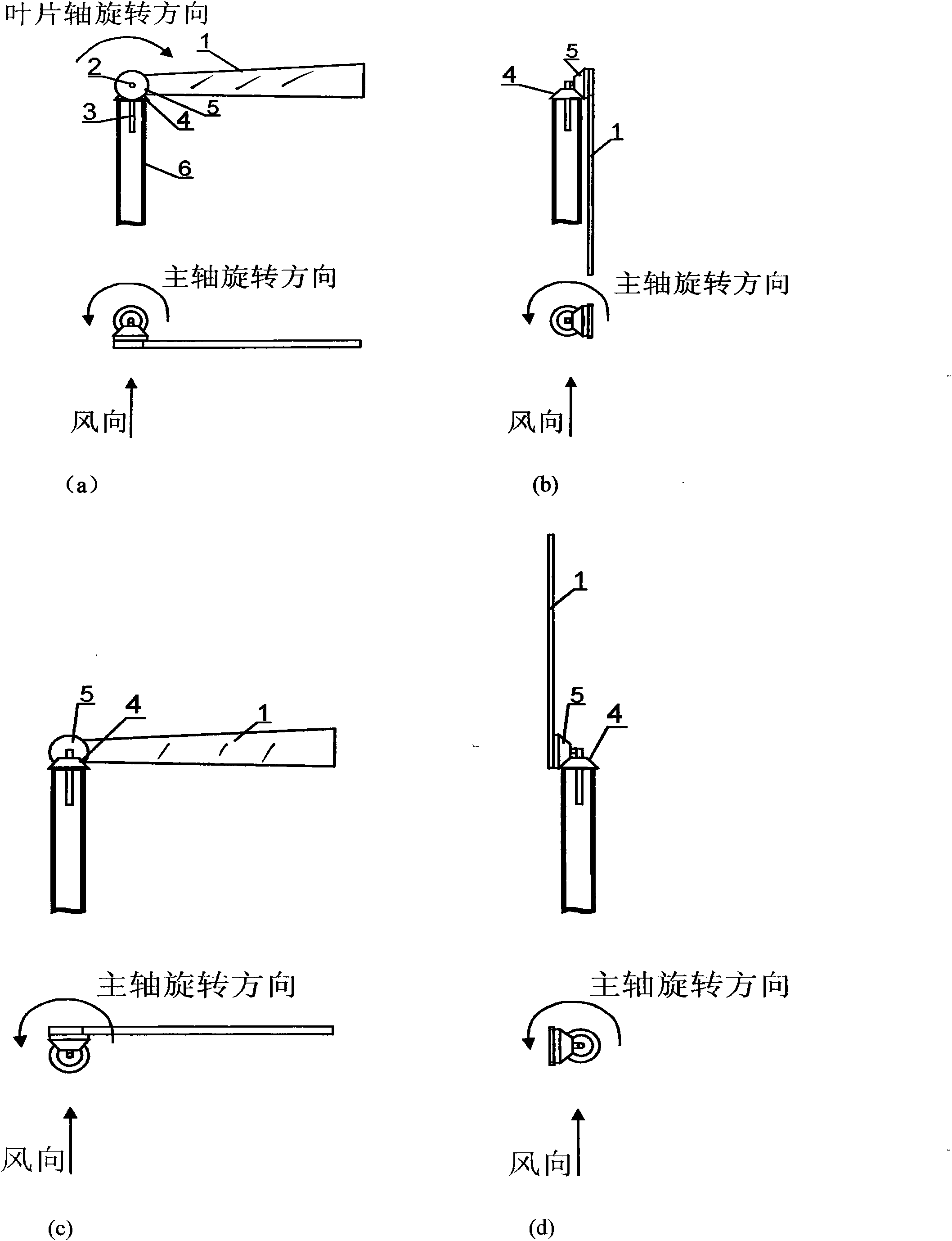

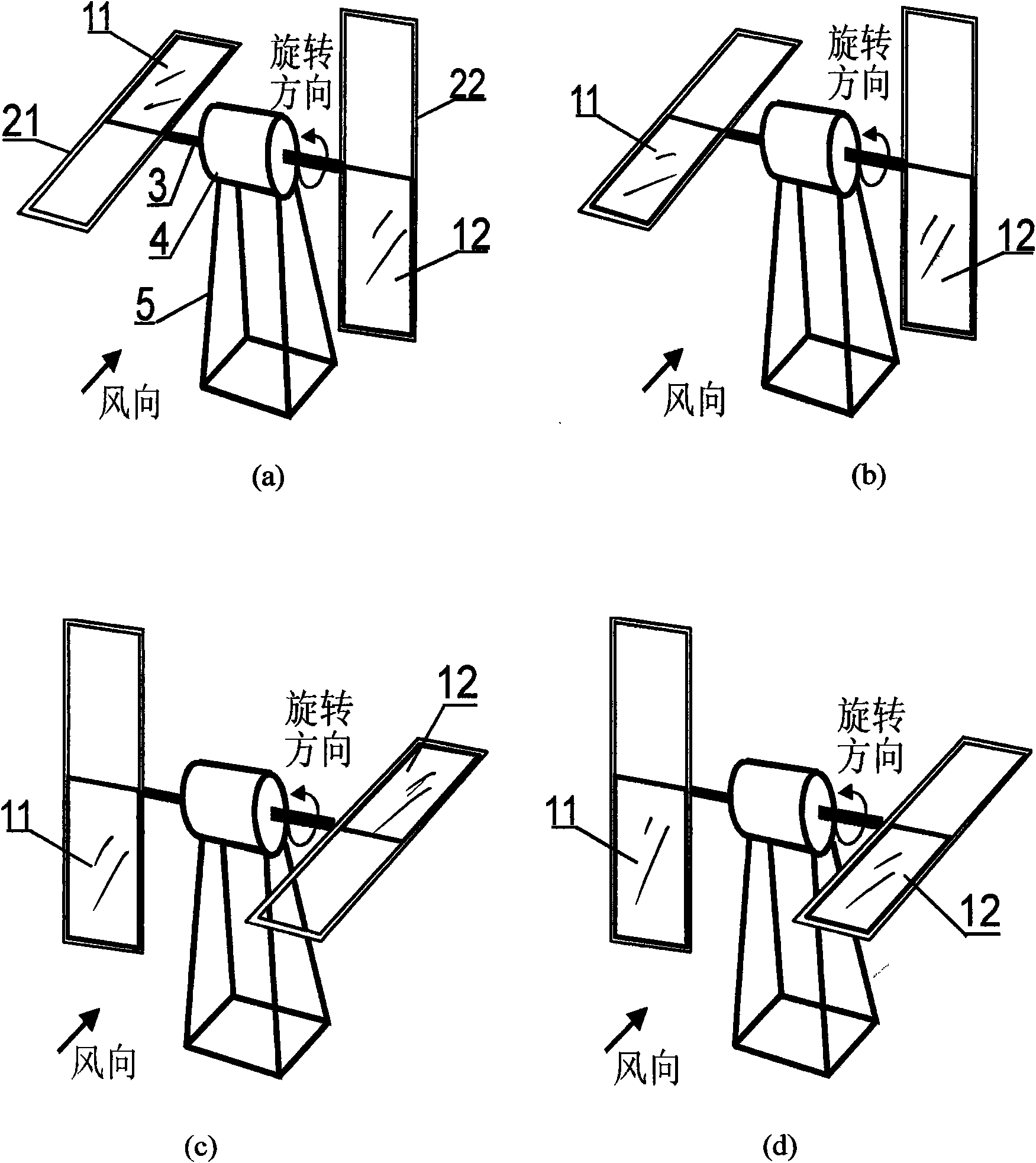

[0014] The present invention will be further described below in conjunction with the accompanying drawings. In this specification, the content description of the orientation is described according to the windward direction. The basic principles and structures of the present invention are also applicable to water turbines. Of course, when the present invention is applied in practice, it should also cooperate with adding such as force balance mechanism, typhoon prevention mechanism, orienting mechanism, etc., as the category of existing technology, this specification does not need to go into details.

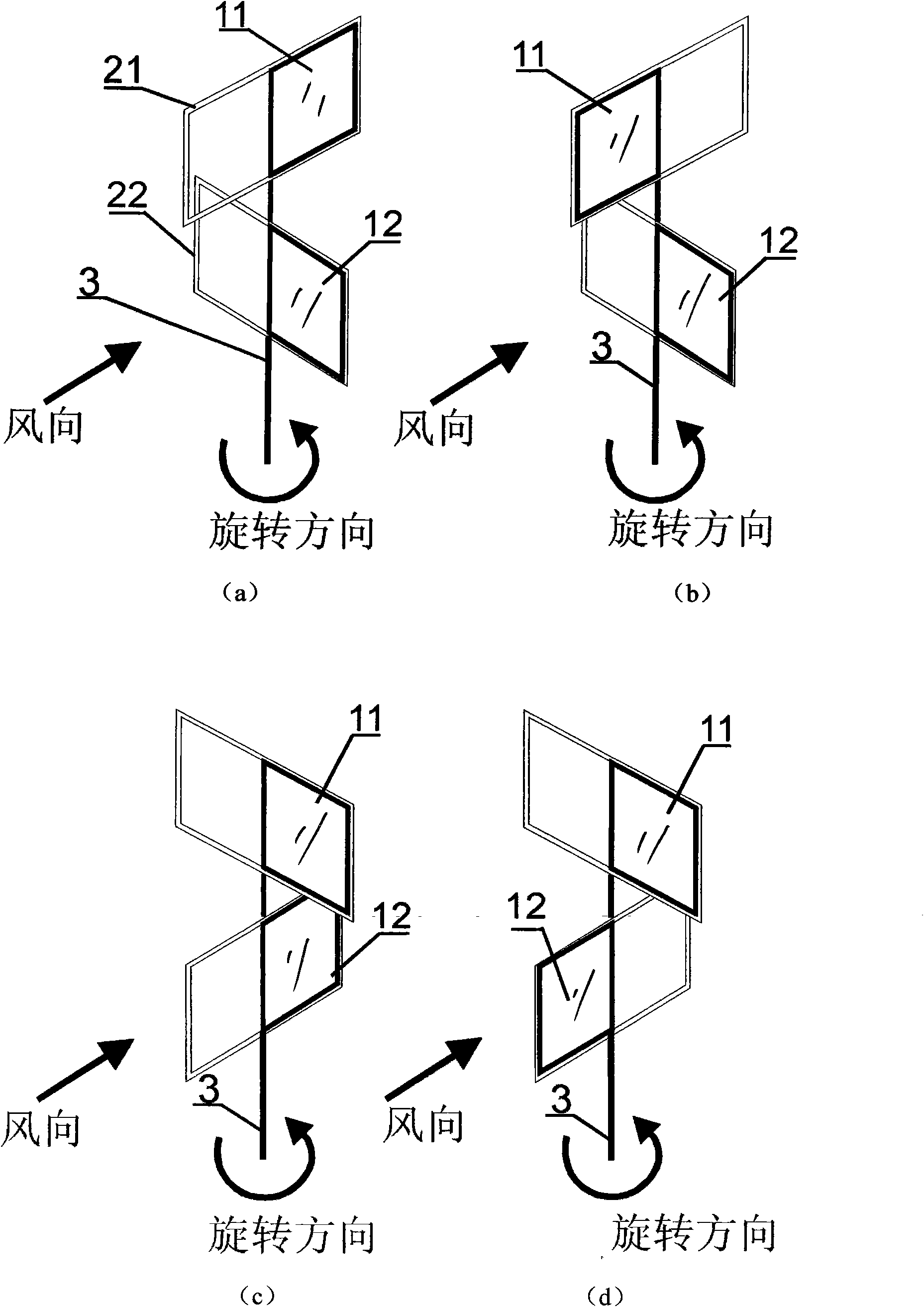

[0015] figure 1 It is a schematic diagram of the principle and action of a preferred embodiment of the present invention, and it is an implementation mode for a vertical shaft wind turbine.

[0016] The vertical shaft wind turbine includes blades 11, 12, blade frames 21, 22, a rotating main shaft 3 and other components. Two blade frames 21 , 22 intersecting at right angles in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com