Power slide device for vehicle seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

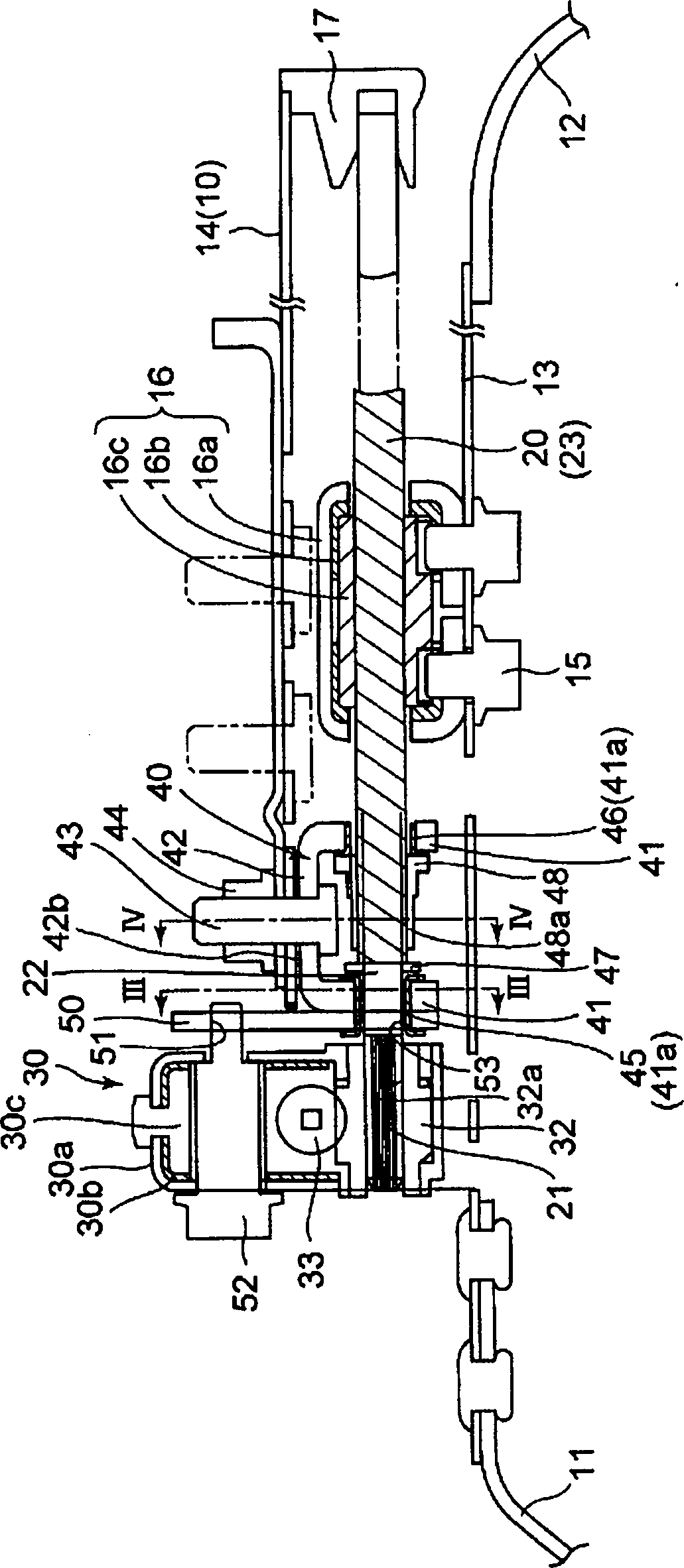

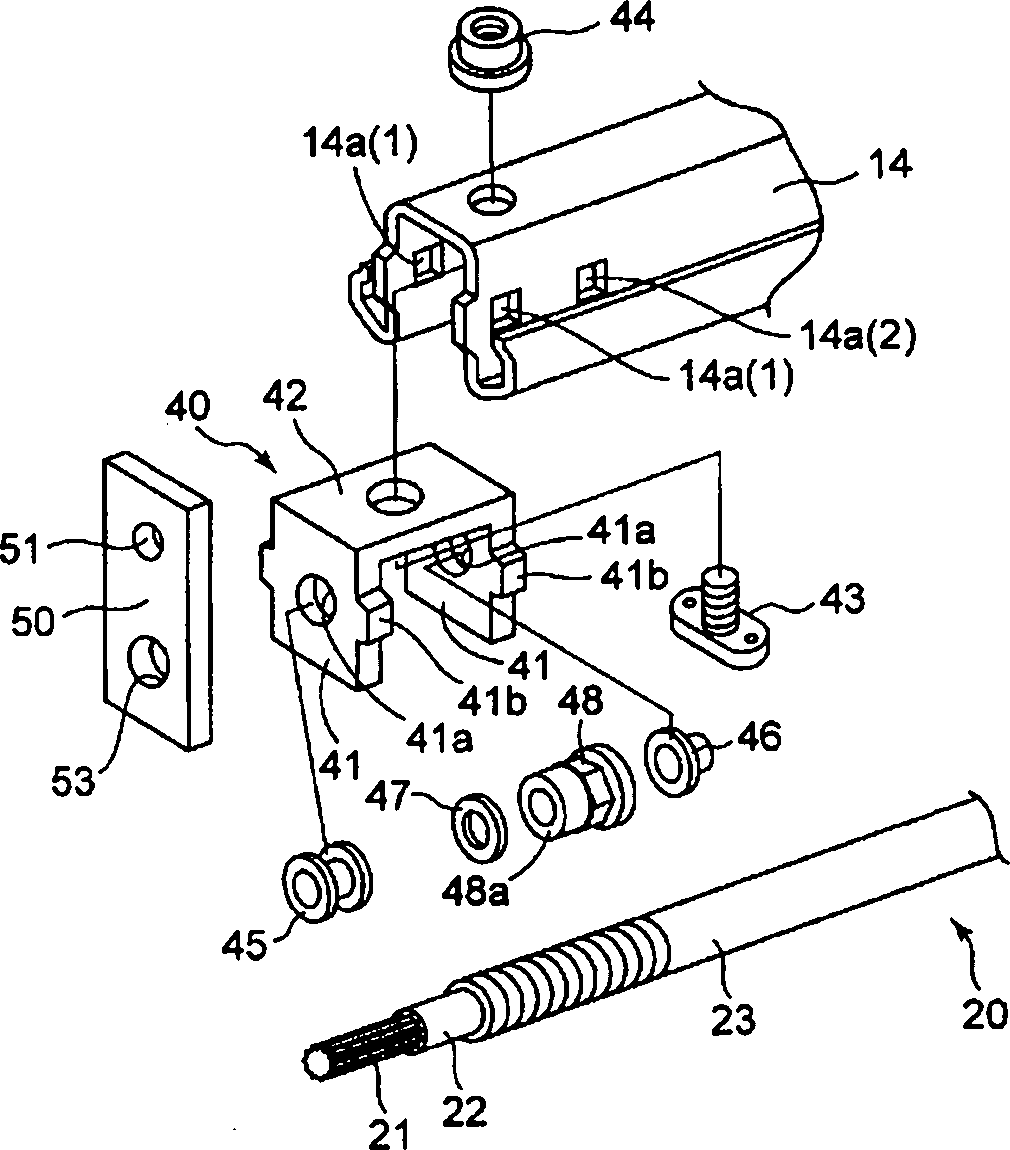

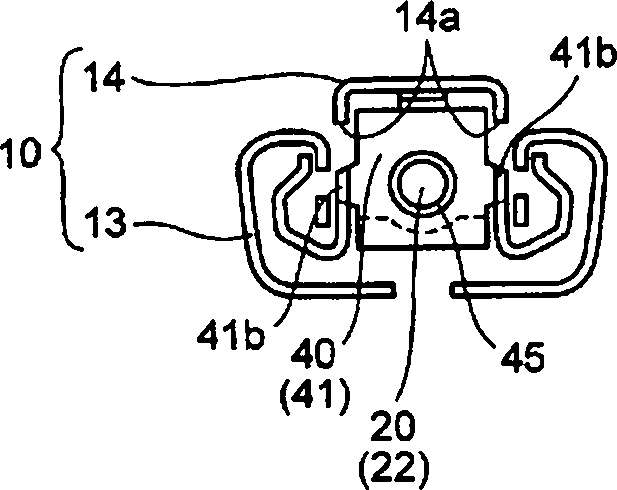

[0080] Such as Figure 13 As shown, the vehicle seat sliding device includes a pair of left and right seat adjustment slide rails 10 located between the vehicle seat S and the ground F and extending in the vehicle front and rear direction. The left and right seat adjustment slide rails 10 have the same (symmetrical) structure, and have a lower rail 13 fixed to the floor F through front and rear brackets 11 and 12, and an upper rail 14 fixed to the seat S, and the lower rail 13 and upper rail 14 are slidably fitted. The lower rail 13 and the upper rail 14 have openings facing each other.

[0081] Such as figure 1 As shown, the feed nut 16 facing the front-rear direction on the axis is fixed to the lower rail 13 by a fixing bolt 15. In the feed nut 16, a nut 16c made of synthetic resin is inserted into a metal casing 16a through a rubber sheet 16b for vibration absorption. The lower rail 13 is a feed nut fixing rail.

[0082] In contrast to this, the screw 20 screwed with the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com