Apparatus for closing containers with a screw closure

A kind of equipment and container technology, which is applied in the direction of capping the container tightly, bottle/container cap, application, etc., and can solve the problems of cap crushing, cracking or bending, production interruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

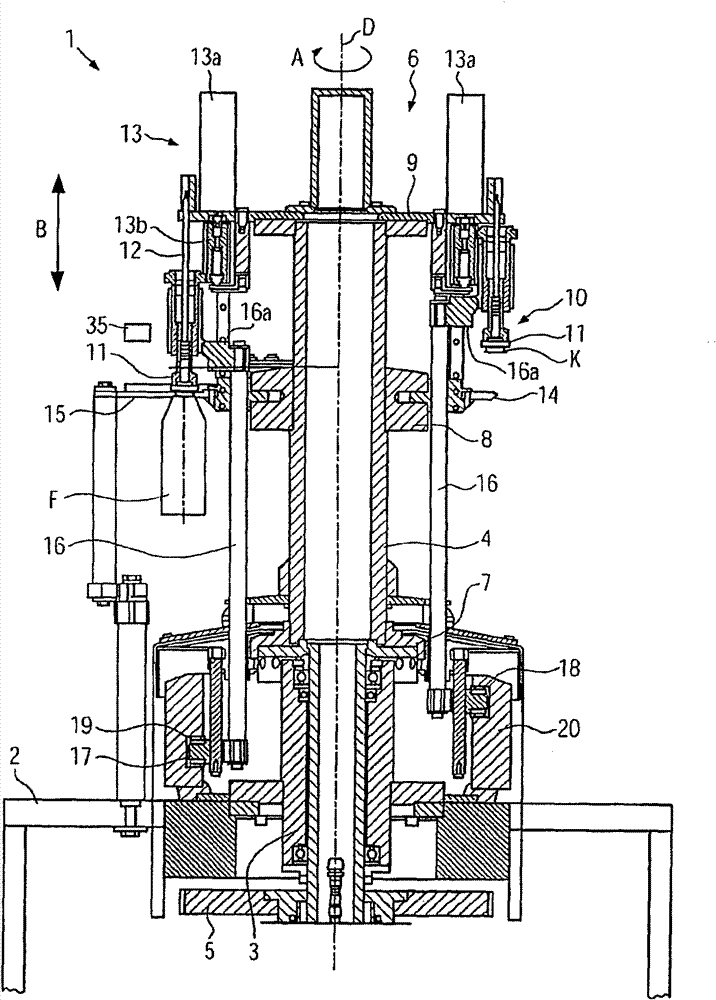

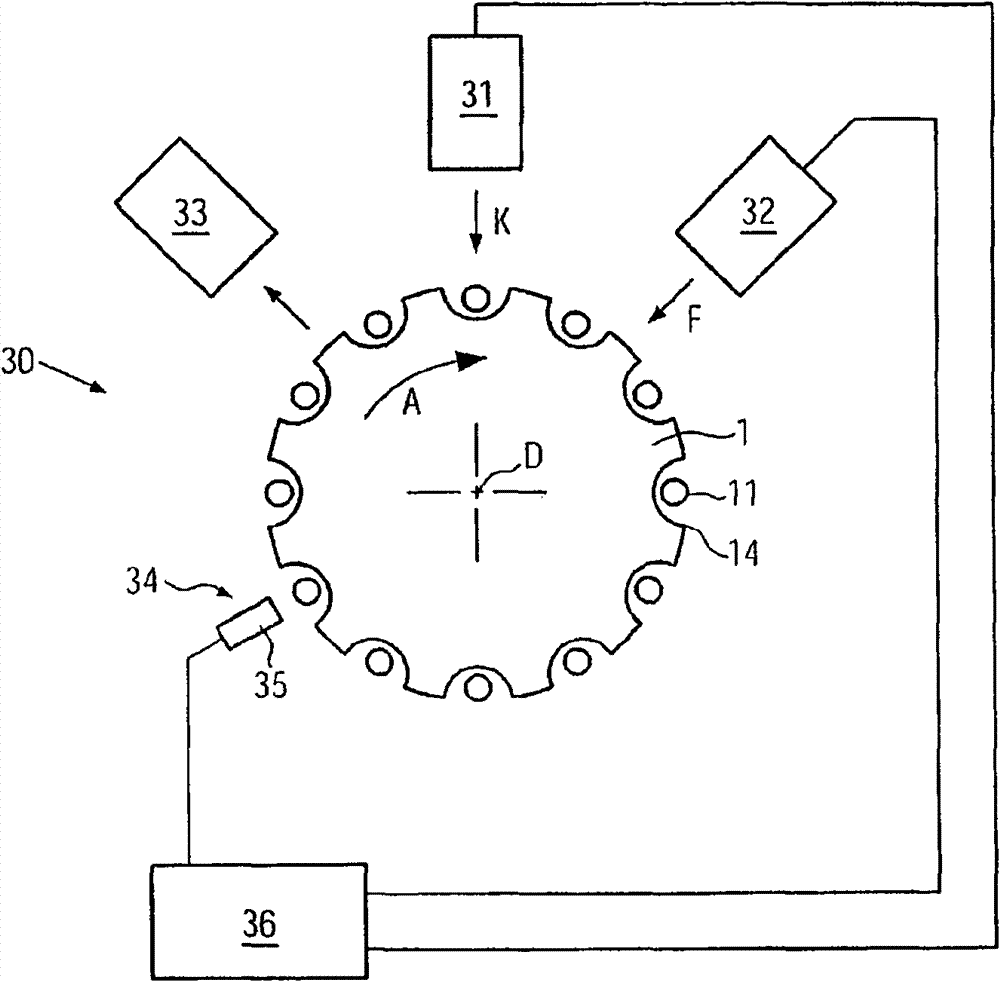

[0014] figure 1 The capping machine 1 is shown in an example illustration. The capping machine 1 corresponds to the capping machine according to EP 1834923, except for the details described below which are provided according to the invention, so that reference is made to this publication for further details. The capping machine 1 is used to screw a cap in the form of a cap K on a beverage bottle F made of plastic. However, the invention is also suitable for screwing top caps or snap caps onto bottles or glasses in a capping machine. The cover usually has an upper cover surface and a cylindrical screw-on flange protruding from this cover surface and provided with a thread on the inside or with a snap-on cover unit.

[0015] The capping machine 1 comprises a stationary base 2 in which a hollow shaft 4 with a vertical axis of rotation D is supported rotatably in the direction of the arrow A by means of a flange bearing 3 . A ring gear 5 is fastened to the lower end of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com