Pinhead assembly device

A technology for assembling devices and needles, which is applied in the field of dialyzers and can solve the problems of low production efficiency and low product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in conjunction with the following examples.

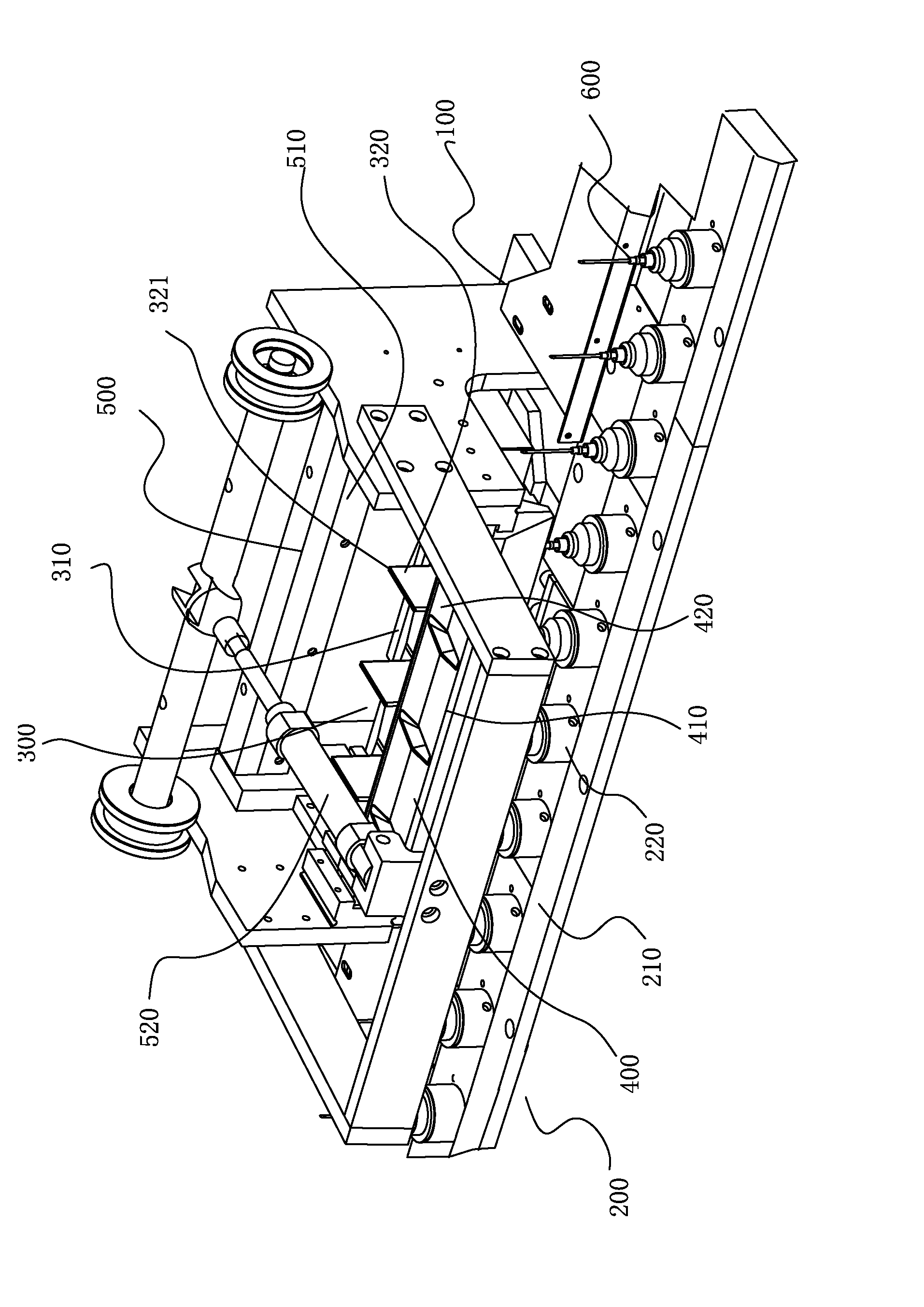

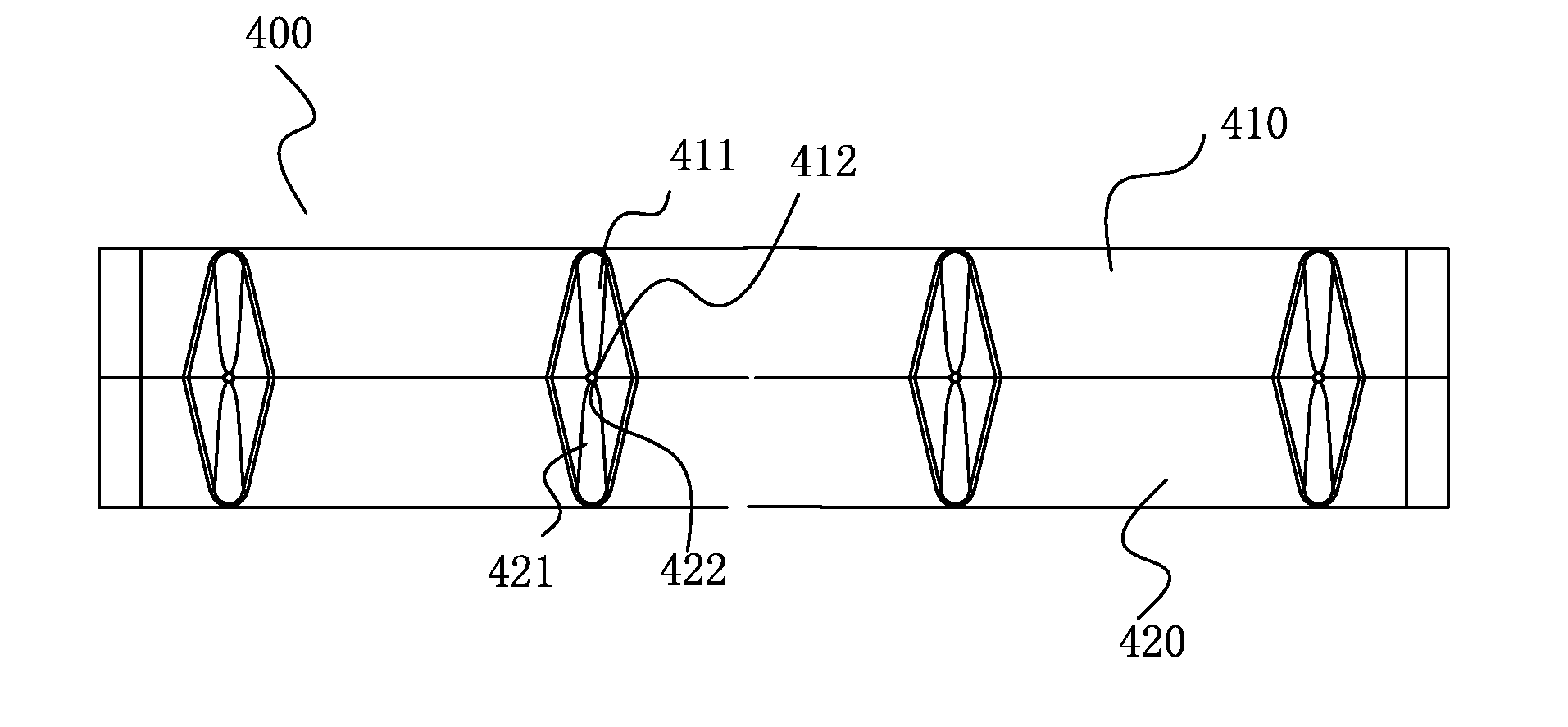

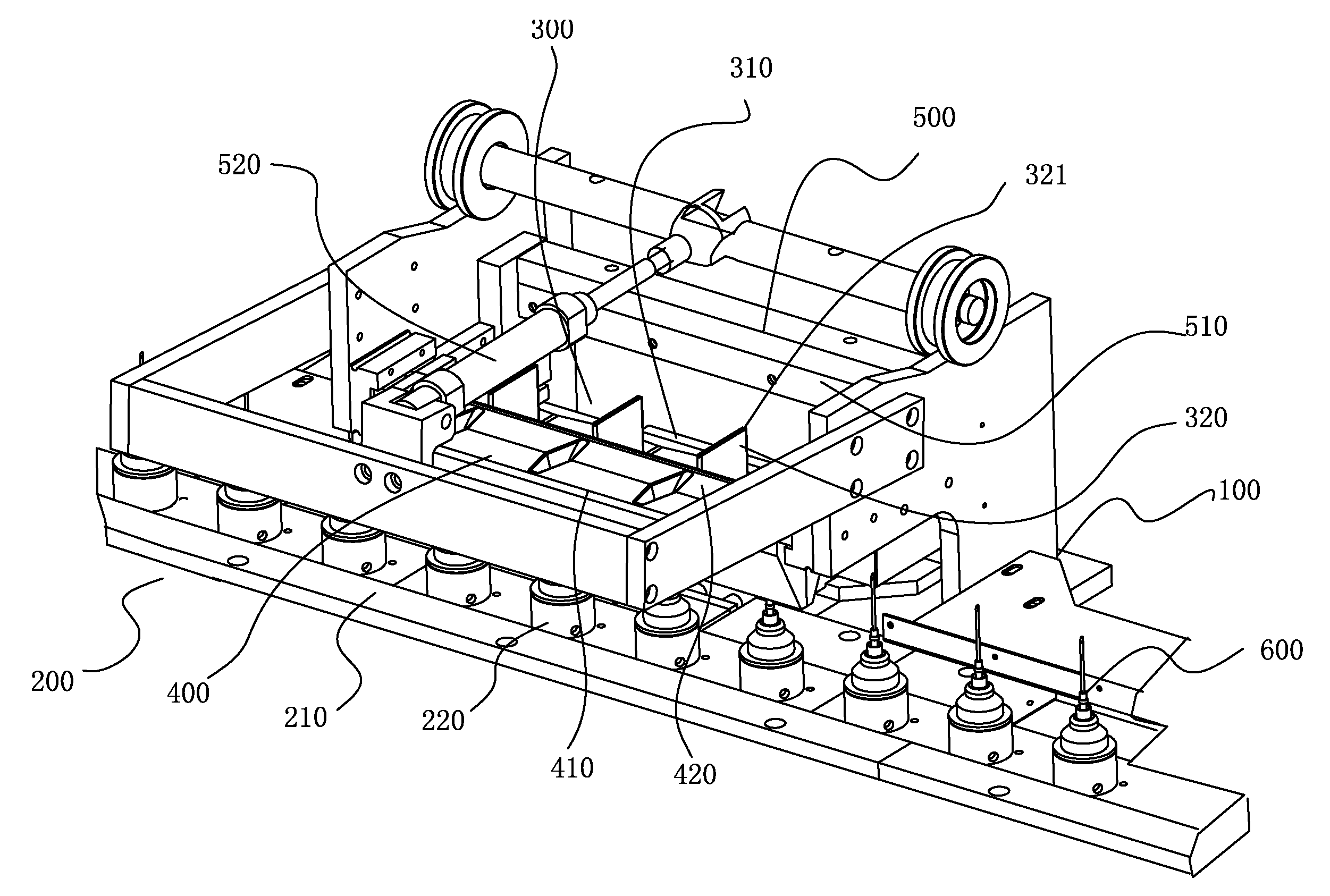

[0044] A needle assembly device such as figure 1 with figure 2 As shown, a frame body 100, an automatic feeding device 200, a needle loading device 300, a needle guide device 400, a pushing device 500 and a control device are provided.

[0045] The automatic feeding device 200, the needle loading device 300, the needle guide device 400 and the pushing device 500 are arranged on the frame body 100, the needle loading device 300 is arranged between the needle guiding device 400 and the pushing device 500, and the automatic feeding device 200 is arranged on the guide Below the needle device 400 , the automatic feeding device 200 , the needle loading device 300 , the needle guiding device 400 and the pushing device 500 are respectively connected with the control device.

[0046] Before the needle assembly process, the needle base has been placed in the automatic feeding device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com