Power hammer

A hammer and power technology, applied in the field of power hammer with clamping mechanism, can solve the problems that the components cannot be parallel to the center line of the casing, and the non-magnetic materials cannot be clamped, so as to achieve increased visibility and compact structure , The effect of shortening the sliding stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

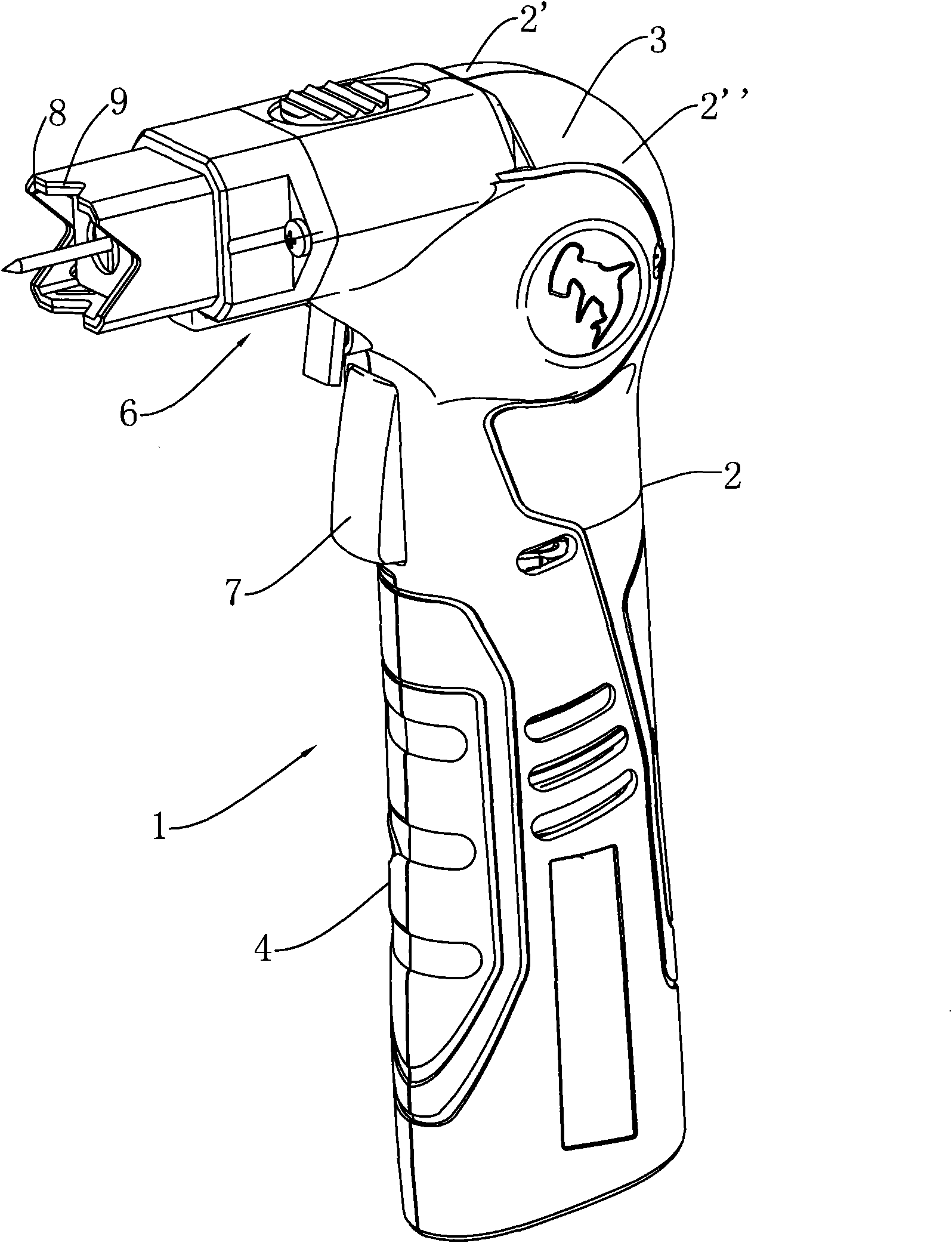

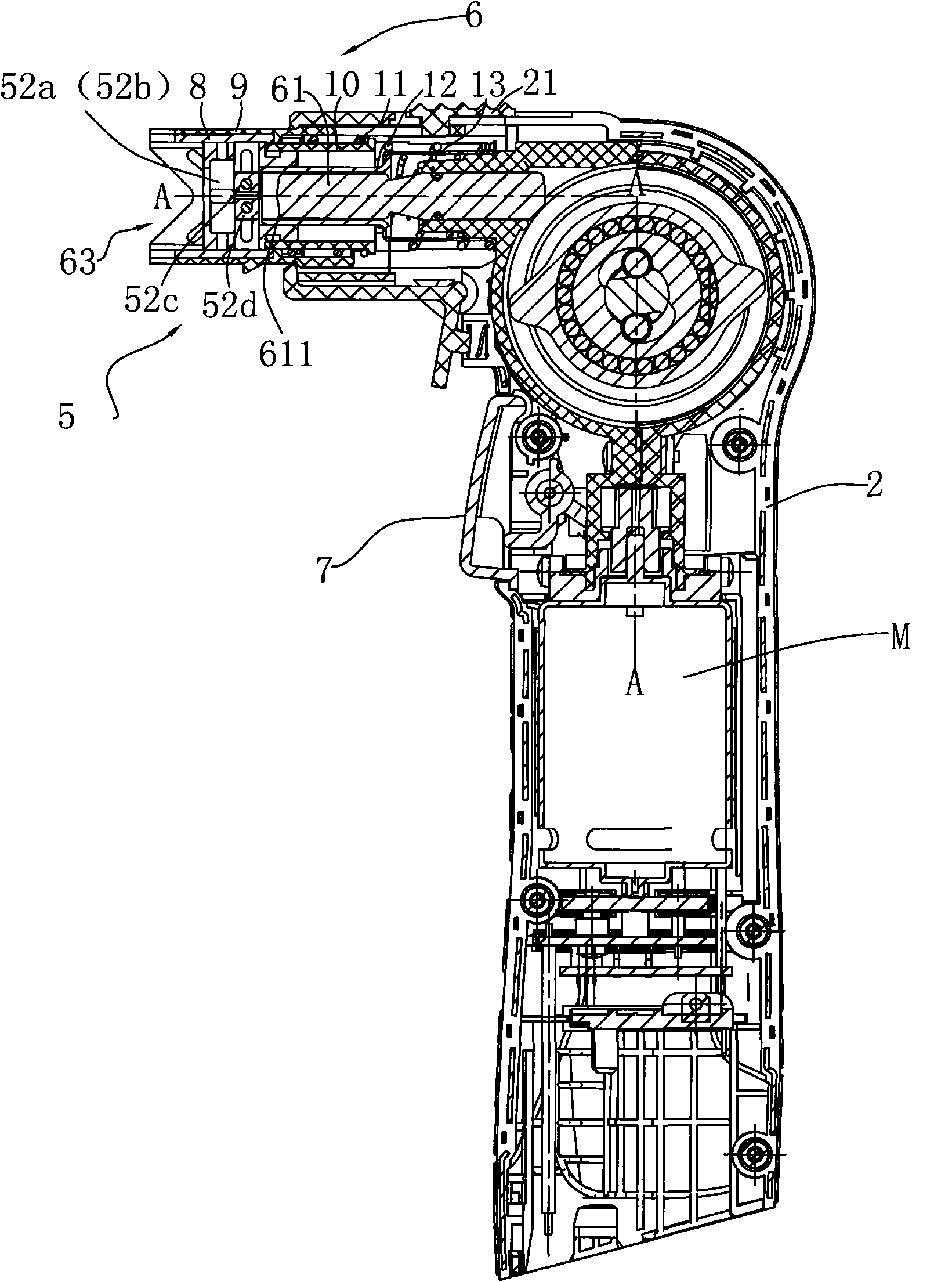

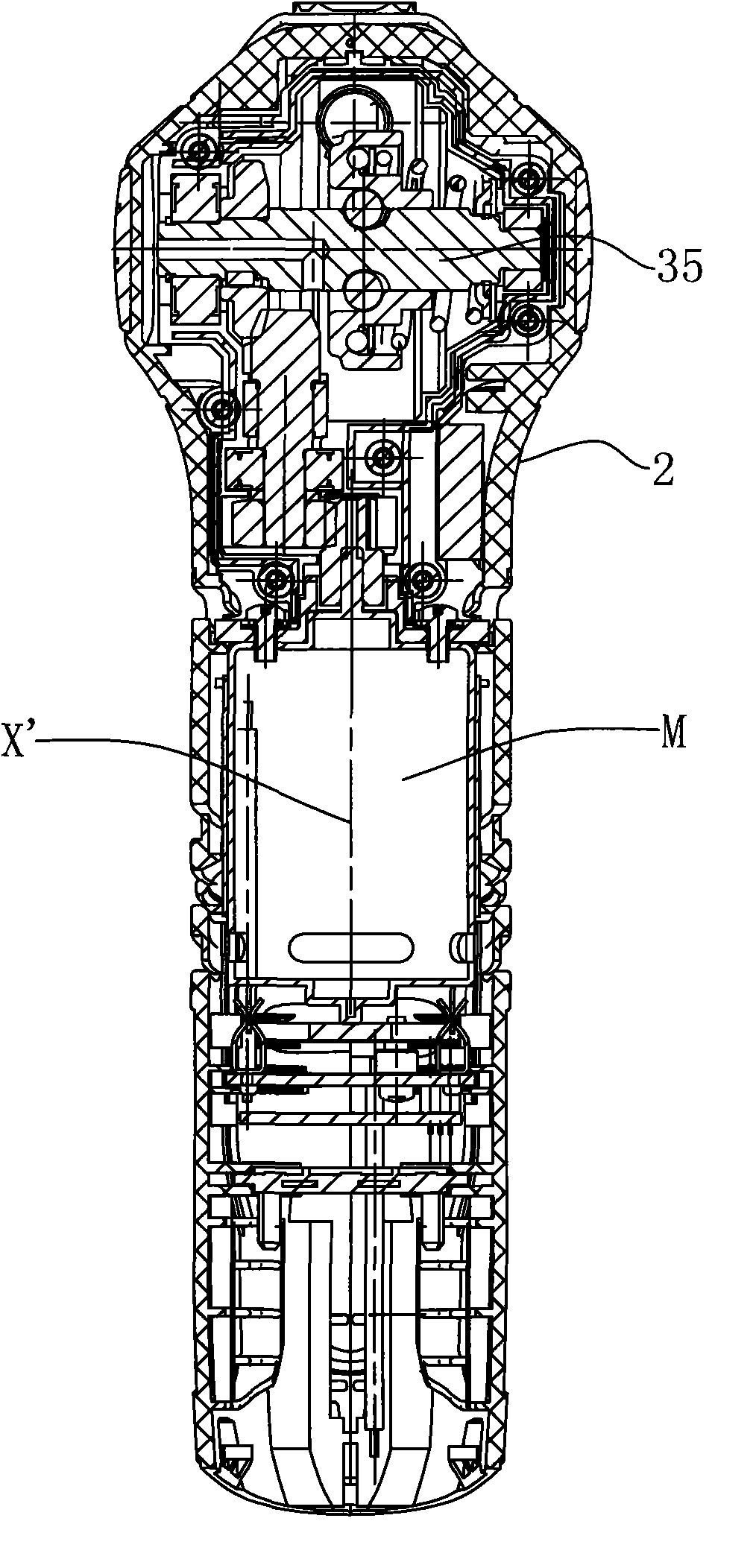

[0037] Such as figure 1 and figure 2 As shown, the power hammer 1 of this embodiment includes a housing 2 containing the motor M and a striking device 6. The housing 2 is formed by joining the left and right halves 2', 2". The main body of the housing 2 Partially forming a substantially vertical gripping portion 4, the upper end contains a head assembly 3, which includes a transmission mechanism and a striking device 6 protruding forward.

[0038] In this embodiment, the power hammer 1 includes a battery pack (not shown) for powering the motor M. However, the power supply method of the power hammer disclosed in the present invention is not limited to this, and AC power can also be used for power supply. The switch 7 is installed on the housing 2 and is used to control the start and stop of the motor M. The beating device 6 includes a beating member 61, which is substantially horizontal, installed in the beating device 6 through a spring, and can perform linear reciprocatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com