Striker plate assembly, spiral distributor and paver

A material blocking board and paver technology, which is applied to roads, road repairs, roads, etc., can solve the problems that the material blocking board is difficult to adapt to the change of road width and affect the quality of road paving, so as to ensure the quality of paving and improve the quality of paving. Service life, guarantee the effect of normal construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

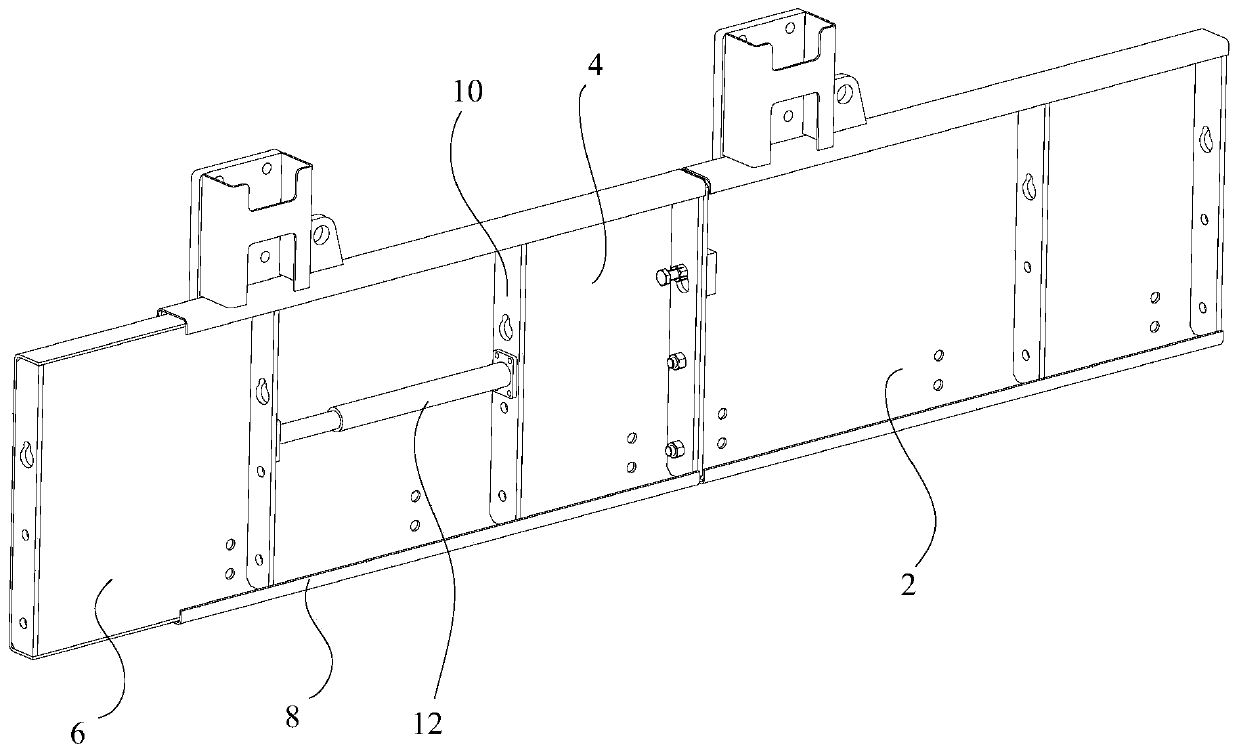

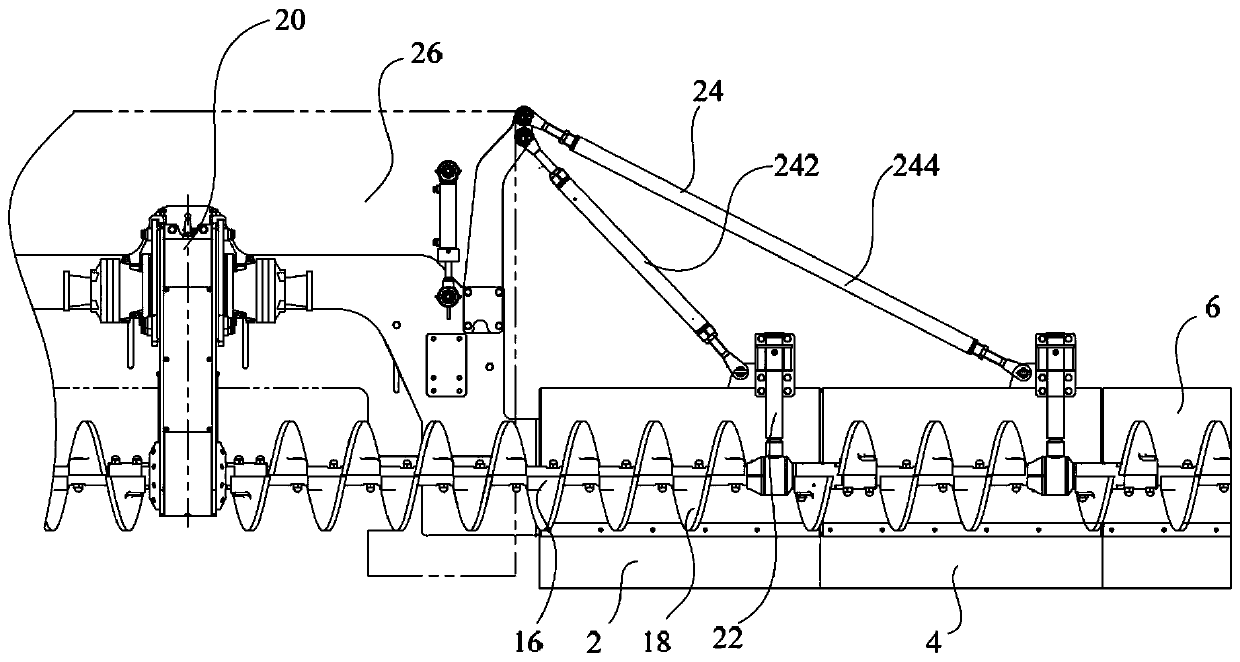

[0050] Such as figure 1 As shown, an embodiment of the present invention provides a material dam assembly, including: a fixed material dam 2 and a telescopic material dam 6 .

[0051] Wherein, the fixed material baffle 2 includes a plurality of fixed sub-material baffles 4, and the plurality of fixed sub-material baffles 4 are sequentially arranged along the length direction of the fixed material baffle 2, and adjacent fixed sub-material baffles 4 can be Disassembly and connection; the telescopic material retaining plate 6 is arranged parallel to the fixed material retaining plate 2, and is slidably connected to the fixed material retaining plate 2, and the telescopic material retaining plate 6 can slide back and forth along the length direction of the fixed material retaining plate 2.

[0052] In the present invention, the material retaining plate assembly includes a plurality of fixed material retaining plates 4 sequentially connected to form a fixed material retaining plate...

Embodiment 2

[0054] Such as figure 1 and figure 2 As shown, an embodiment of the present invention provides a material dam assembly, including: a fixed material dam 2 and a telescopic material dam 6 .

[0055] Wherein, the fixed material baffle 2 includes a plurality of fixed sub-material baffles 4, and the plurality of fixed sub-material baffles 4 are sequentially arranged along the length direction of the fixed material baffle 2, and adjacent fixed sub-material baffles 4 can be Disassembly and connection; the telescopic material retaining plate 6 is arranged parallel to the fixed material retaining plate 2, and is slidably connected to the fixed material retaining plate 2, and the telescopic material retaining plate 6 can slide back and forth along the length direction of the fixed material retaining plate 2.

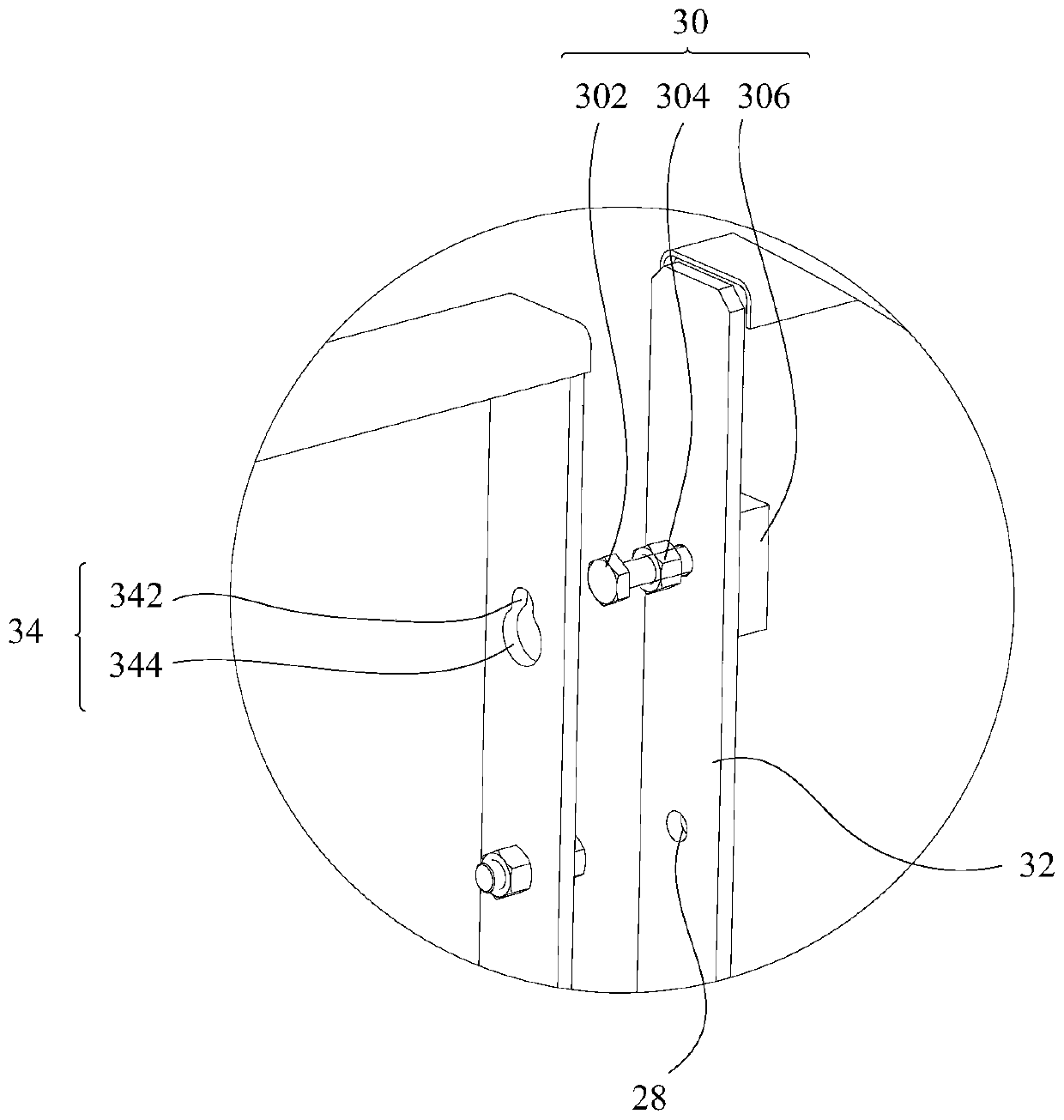

[0056] Such as figure 2 As shown, further, the material baffle assembly further includes: a limit connection hole 28, which is arranged on the connection side of two adjacent ...

Embodiment 3

[0063] Such as figure 1 and figure 2 As shown, an embodiment of the present invention provides a material dam assembly, including: a fixed material dam 2 and a telescopic material dam 6 .

[0064] Wherein, the fixed material baffle 2 includes a plurality of fixed sub-material baffles 4, and the plurality of fixed sub-material baffles 4 are sequentially arranged along the length direction of the fixed material baffle 2, and adjacent fixed sub-material baffles 4 can be Disassembly and connection; the telescopic material retaining plate 6 is arranged parallel to the fixed material retaining plate 2, and is slidably connected to the fixed material retaining plate 2, and the telescopic material retaining plate 6 can slide back and forth along the length direction of the fixed material retaining plate 2.

[0065] Such as figure 1 As shown, further, the material baffle assembly further includes: a chute 8, which is arranged on a part of the fixed sub material baffles 4 among the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com