Balance valve with quickly-closing valve plug

A technology of balance valve and valve core, applied in the field of balance valve, can solve the problems of prolonged valve core closing time, dangerous smooth operation of the whole machine, large sinking distance of heavy objects, etc., to achieve strong design reliability, perfect design function, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

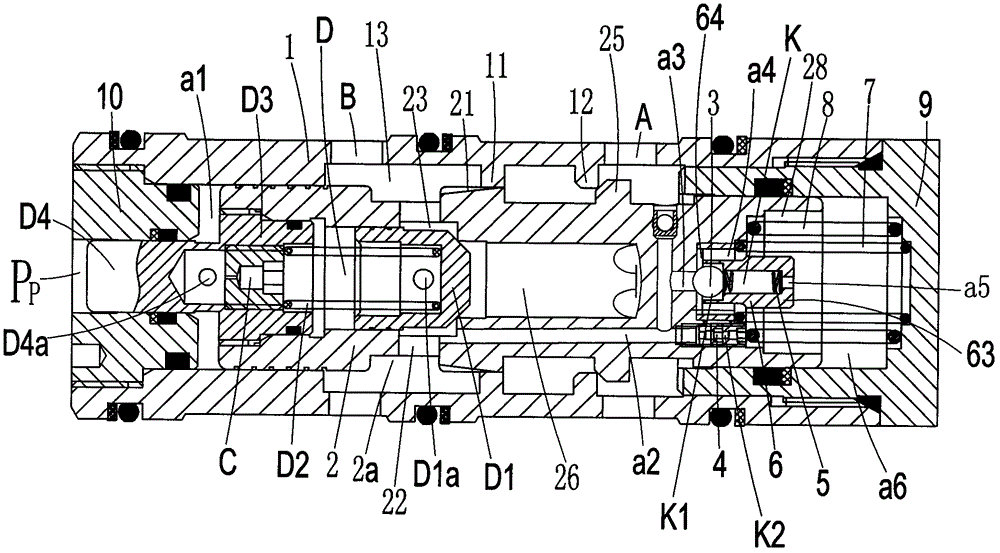

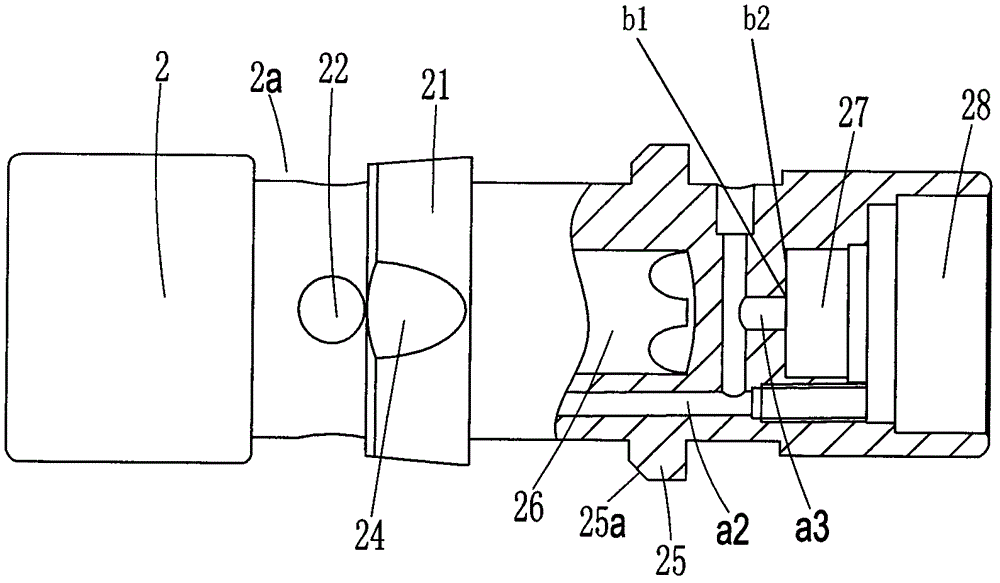

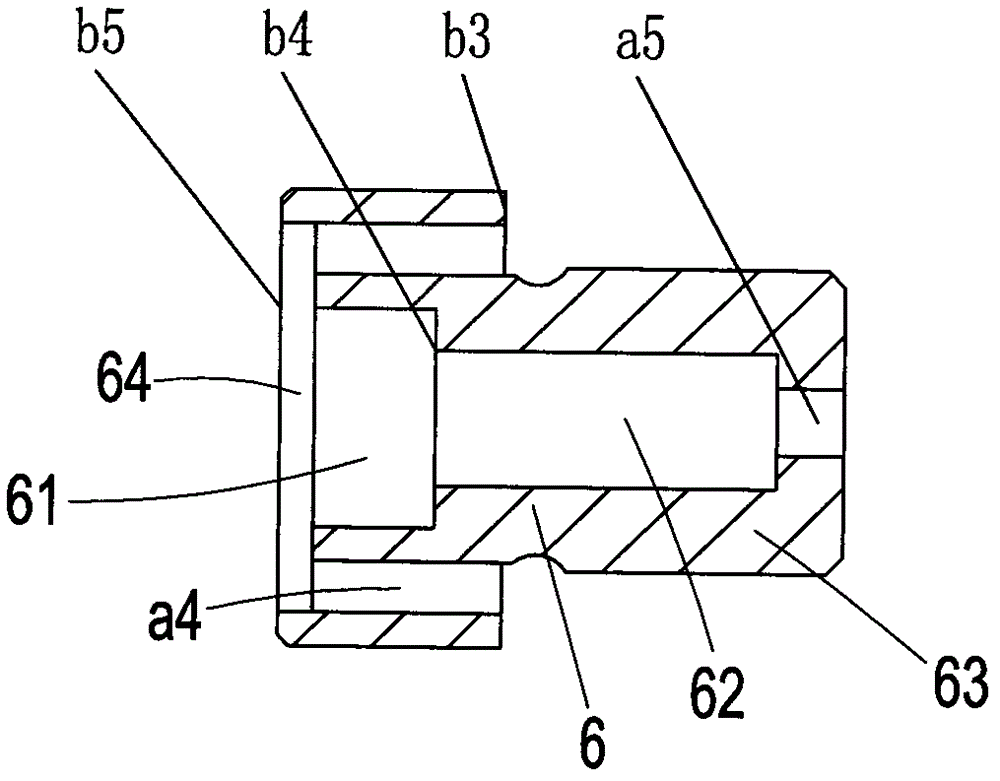

[0028] Such as Figure 1 to Figure 4 As shown, the icon numbers are explained as follows: valve sleeve 1, front stop ring 11, rear stop ring 12, through hole 13, main valve core 2, inner concave ring body 2a, front cut-off body 21, perforation 22, front one-way Valve hole 23, throttle groove 24, rear stop body 25, inclined surface 25a, intermediate transition hole 26, spring cover hole 27, rear concave hole 28, steel ball 3, damping 4, steel ball spring 5, spring cover 6, steel ball hole 61, spring hole 62, pin-shaped body 63, ring hole 64, small coil diameter spring 7, large coil diameter spring 8, rear end cover 9, front end cover 10, first main oil port A, first working oil port A1, Second main oil port B, second working oil port B1, fourth working oil port B2, third working oil port B3, leakage damping C, main check valve assembly D, plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com