Mobile engineering machine and control system of support leg thereof

A technology for construction machinery and control systems, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve the problem that outriggers cannot provide support for mobile construction machinery, reduce the state conversion control operation efficiency of mobile construction machinery, Mobile construction machinery overturning and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

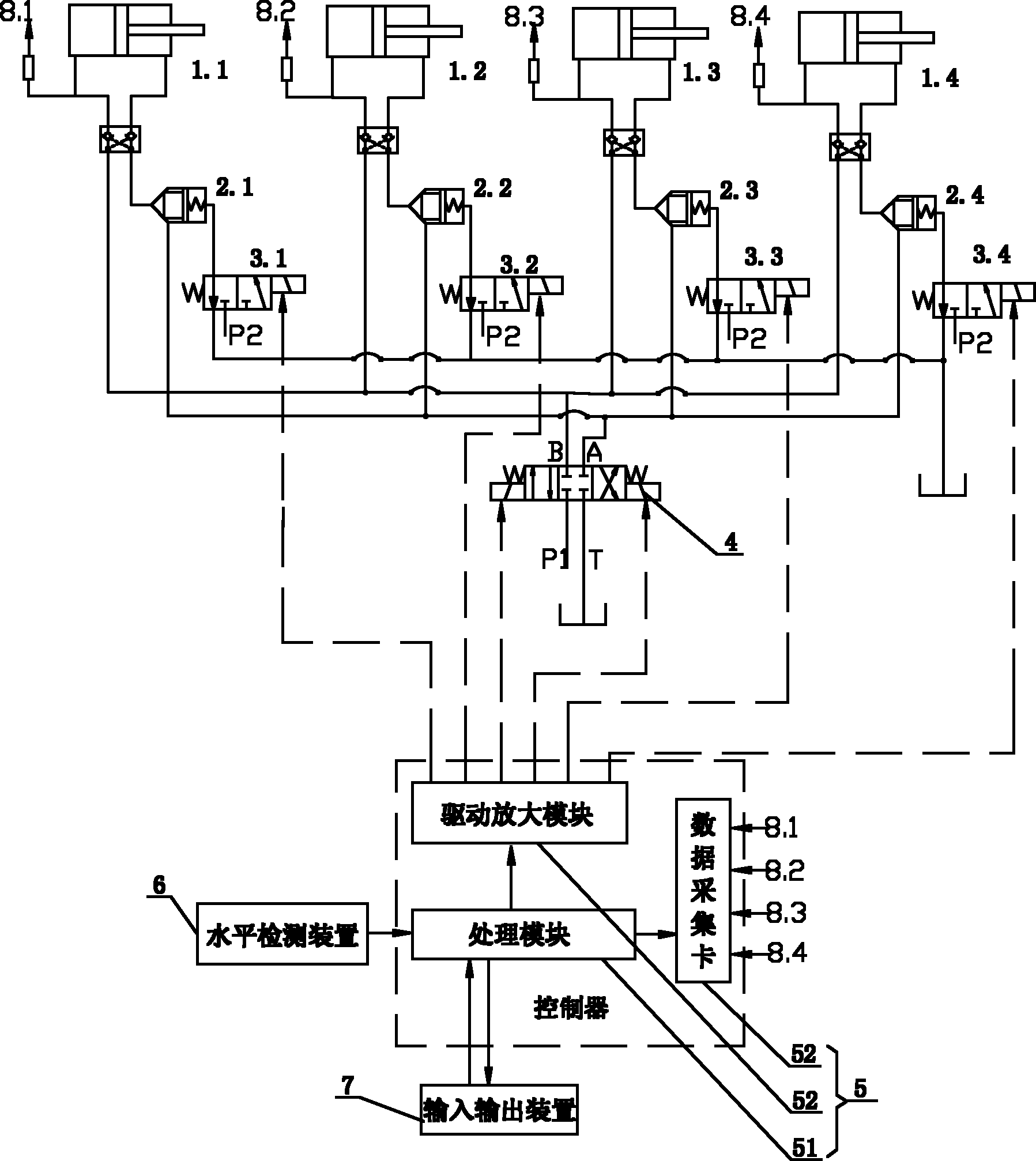

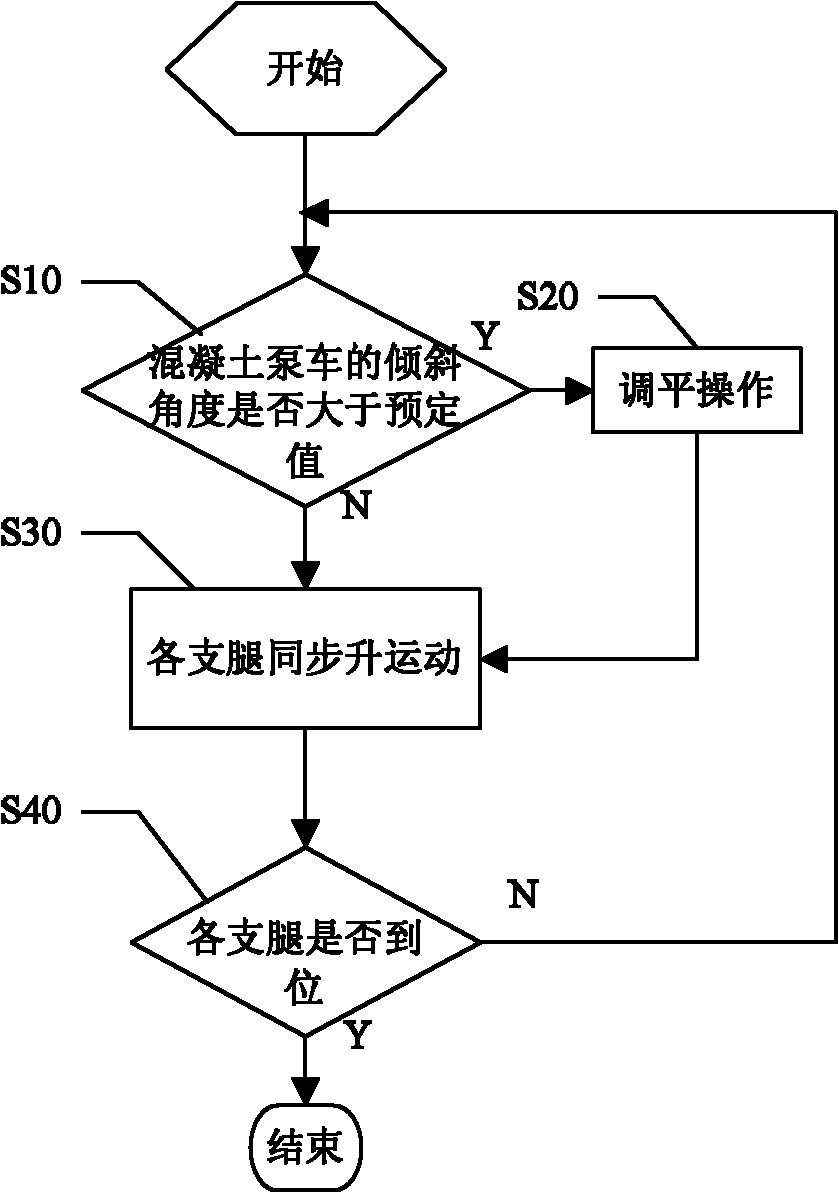

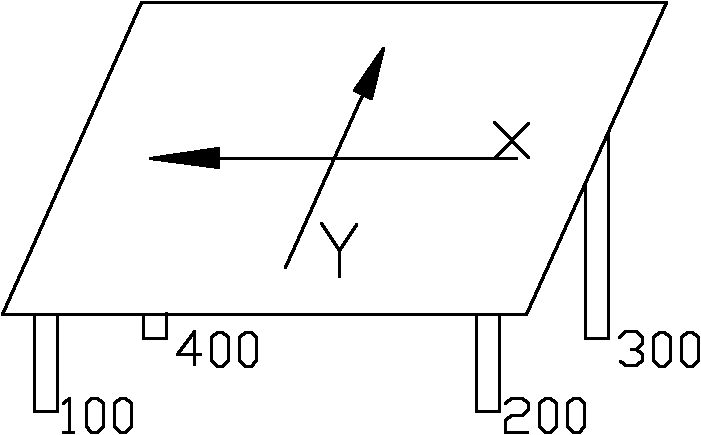

[0035] In the first embodiment, the control system of the outriggers of the mobile construction machinery includes a controller 5, a level detection device 6 and four hydraulic control devices. The level detection device 6 is connected to the input terminal of the controller 5 .

[0036] Level detection device 6 is installed in the appropriate position of concrete pump truck, is used to detect the tilt angle of concrete pump truck; Level detection device 6 can be angle sensor; In this example, level detection device 6 is a biaxial angle sensor, to obtain the The angle between the vehicle in the direction of two detection reference axes and a reference horizontal plane. The angle information acquired by the level detection device 6 can be transmitted to the controller 5, and the controller 5 can determine the inclination angle of the concrete pump truck according to the acquired angle information, and then determine the inclination angle according to a predetermined strategy. ...

Embodiment 2

[0078] Embodiment 2 The working principle of the hydraulic control device is as follows:

[0079] When each outrigger oil cylinder 1 needs to be extended synchronously, the reversing valve 4 is positioned at the left position by the controller 5 (with Figure 6 For reference); and the pilot switch valve 3.1, 3.3, 3.5, 3.7 is located in the right position through the controller 5, so that the hydraulic oil flows into the rodless cavity of each leg cylinder 1 through the reversing valve 4; each leg cylinder The hydraulic oil in the rod cavity in 1 flows back into the oil return circuit through the cartridge valves 2.1, 2.3, 2.5, and 2.7 respectively, and each outrigger cylinder 1 extends out synchronously. During the leveling operation, when part of the outrigger cylinder 1 needs to be stretched out, the reversing valve 4 is kept in the left position, and the part of the pilot switch valves 3.1, 3.3, 3.5, and 3.7 are placed in the right position through the controller 5, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com