Optical fiber annealing extension tube used for high-speed drawing

An extension tube and wire drawing technology, which is applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems that the extension tube can only reach 1.2m, and it is difficult to take out the extension tube, and achieves great popularization and application value. Lightweight and warp-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail:

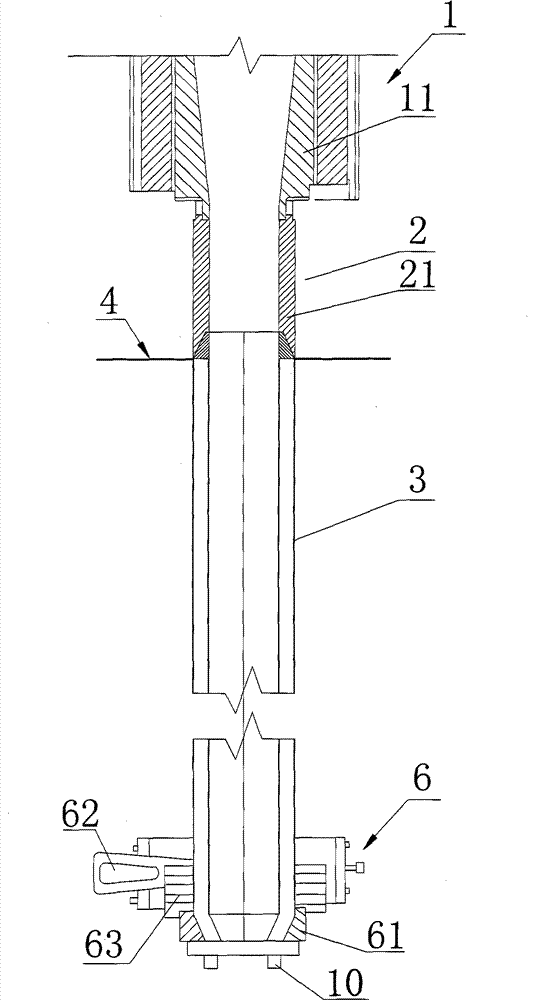

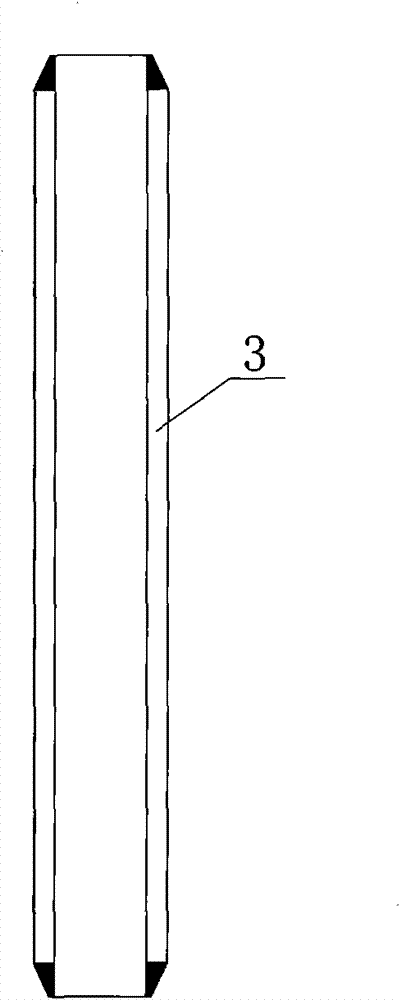

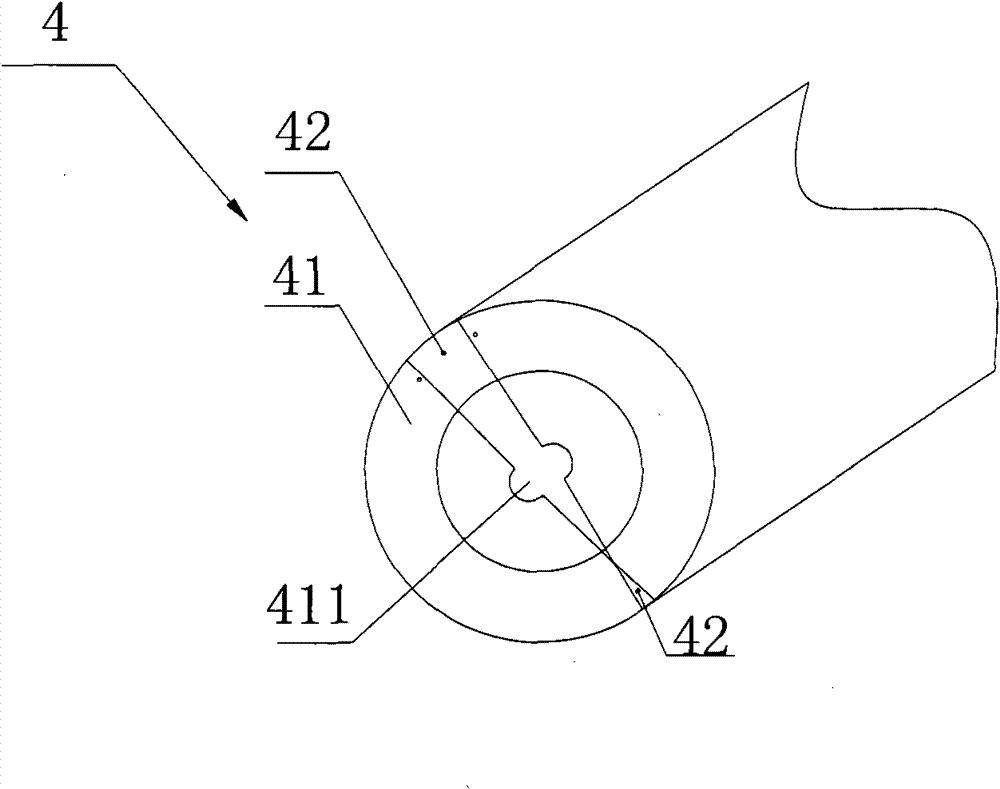

[0023] Such as figure 1 The annealing extension tube shown is mainly composed of two detachably connected tube bodies. The upper part of the tube body is a metal tube 2, which is fixed under the optical fiber drawing furnace 1. The inner wall of the metal tube 2 is coated with a graphite insulation layer 21, which is correspondingly connected to the graphite muffle tube 11 in the drawing furnace 1. Below the metal tube 2 is a glass tube 3, the glass tube 3 is a double-layer structure, and there is a vacuum state between the two layers, such as figure 2 As shown, the upper and lower ends of the glass tube 3 are solid, and the upper end is inserted in the metal tube 2 . The vacuum double-layer glass tube can effectively prevent the loss of heat in the entire extension tube, thereby improving the warpage of the optical fiber. In order to protect the g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap