Pipe joint for vacuum pouring technology

A technology of vacuum infusion and pipe joints, which is applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, elbows, etc., which can solve the problems of glue injection pipe falling off, product defects, complicated operation, etc., and achieve the effect of convenient sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the improvements made by this patent to the prior art, the specific description is as follows in conjunction with the accompanying drawings:

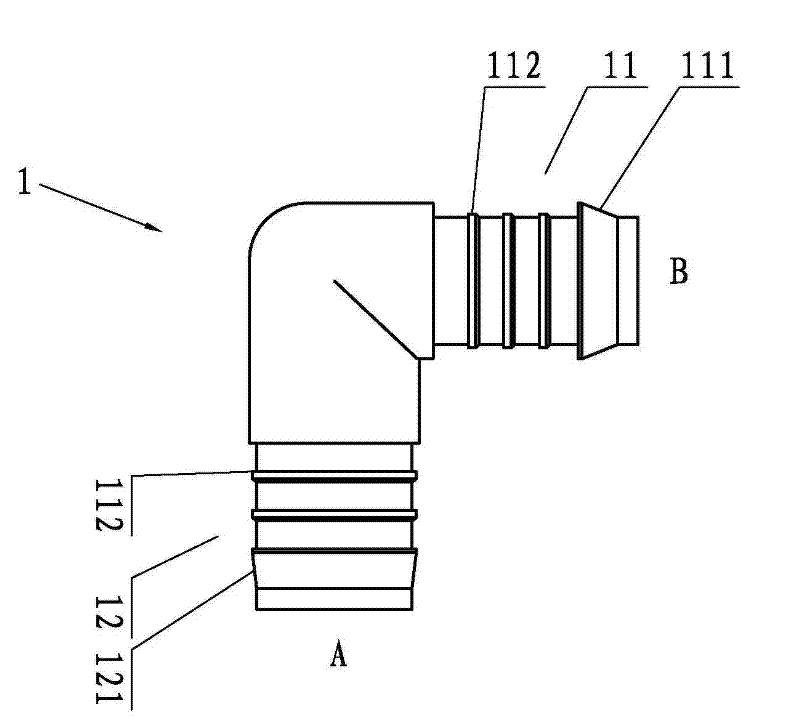

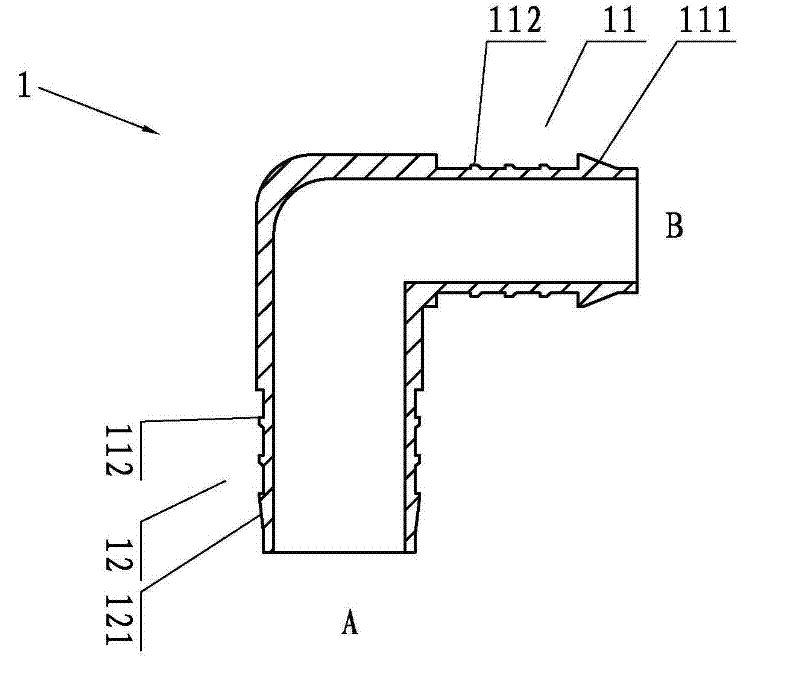

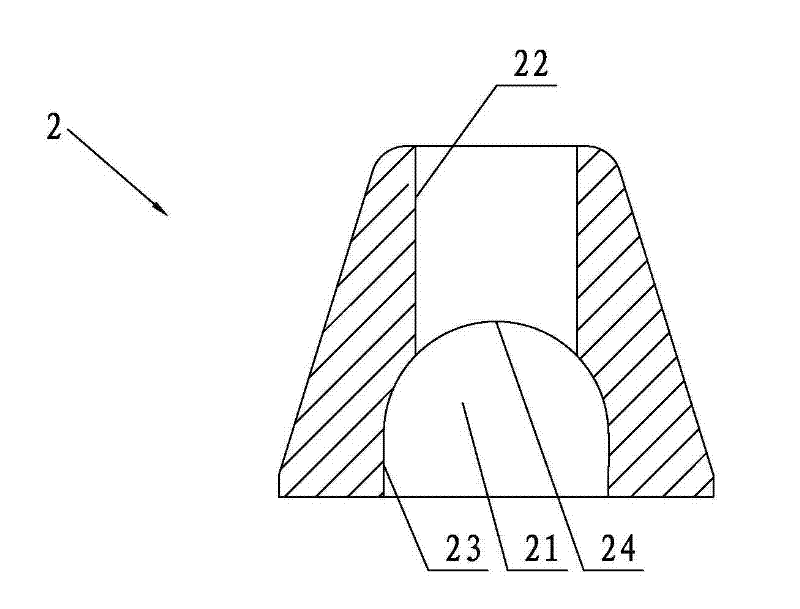

[0036] The invention provides a pipe joint of a vacuum infusion process, such as Figure 1-4 As shown, it includes: a plug piece 1, which has a conductive glue injection joint end and a glue guide joint end, and the outer side of the glue injection joint end has a pipe joint 12, and the pipe joint 12 can be sealed and connected to the glue injection pipe. , and the outer side of the glue joint end has a clamping part 11; and a glue injection block 2, which has a chamber 21 whose bottom is connected to the glue pipe, and the upper part of the chamber 21 has a glue guide joint for the plug The accommodating hole 22 inserted at the end, and the inner end of the accommodating hole 22 has a locking part 24, the locking part 11 can be locked on the locking part 24, and all seams are sealed with sealant T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com