Printed shell fabric

A fabric and printing technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems that cannot meet the requirements of novel and innovative clothing materials, achieve good gloss and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

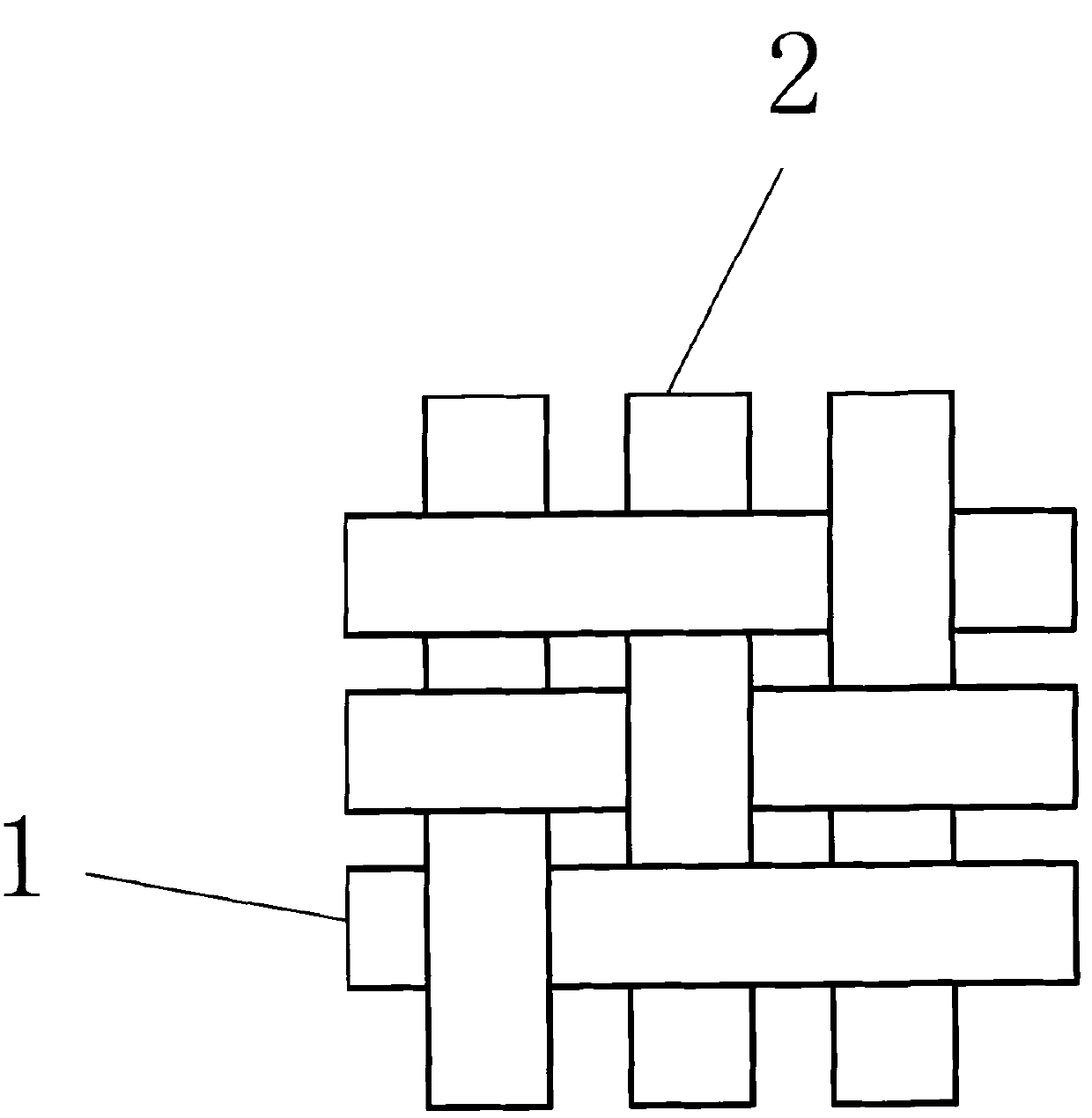

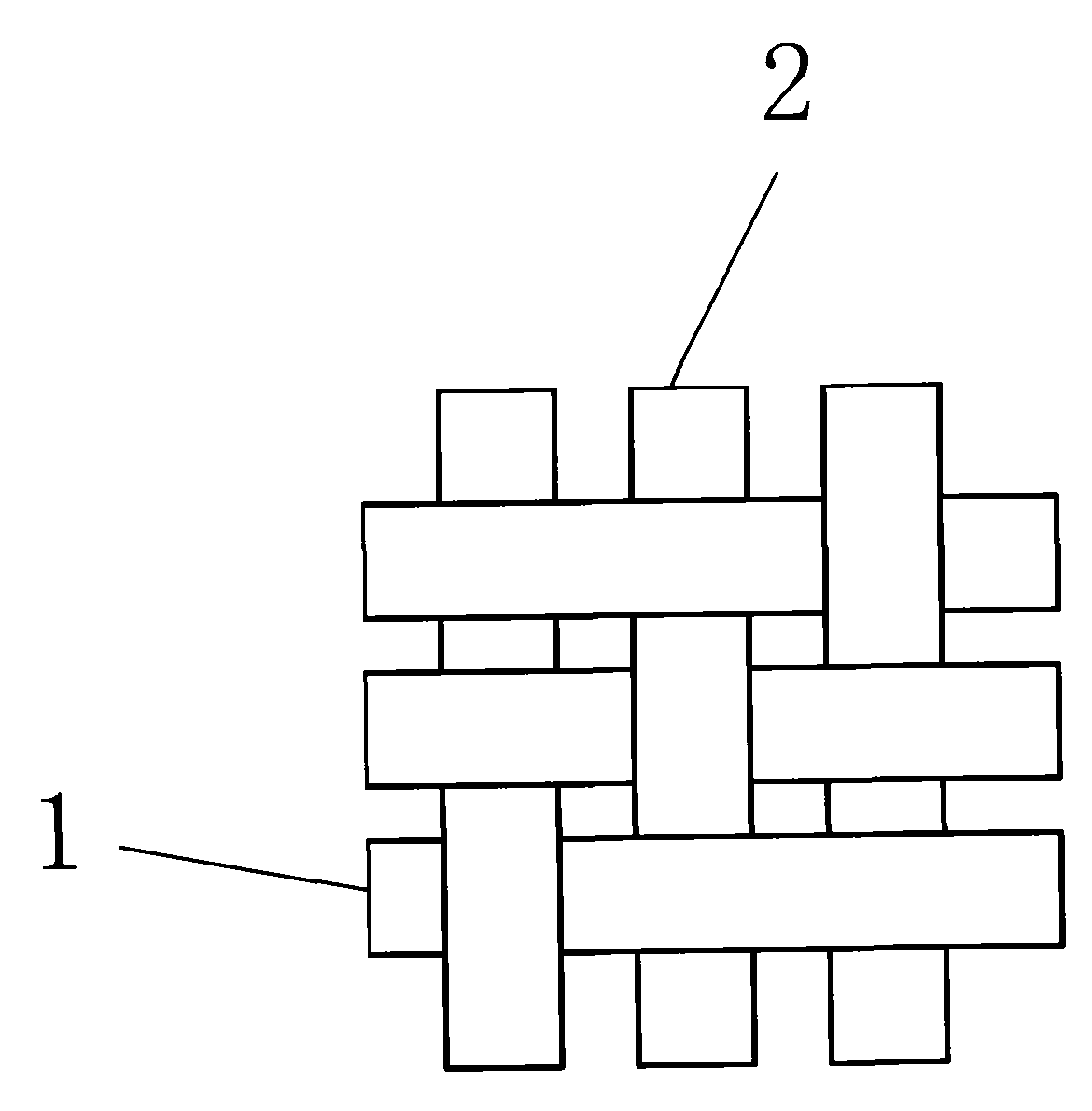

[0011] The concrete structure of the present invention will be described in detail below with reference to accompanying drawing:

[0012] Refer to attached figure 1 Shown: a printed fabric, which is formed by interweaving warp yarn 1 and weft yarn 2. The warp yarn and weft yarn are 50D polyester. After warping treatment, the warp yarn density of the fabric is 249-251 / inches; the density of weft yarns is 134-136 threads / inch, and the fabric weave adopts variable twill weave.

[0013] The raw material is: the above-mentioned fabric is obtained through warping, weaving, and finishing. in,

[0014] Warping: During warping, warp 1 and weft 2 are warped and then brought together. The tension of each warp yarn 1 must be uniform during warping, otherwise it is easy to cause warp flow on the cloth surface during weaving; there is a certain inclination angle during warping. If the displacement is inaccurate, it may cause the warp yarn 1 to warp and affect the fabric surface; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com