Automatic shuttle peg feeder for automatic ground thread replacing device of computerized embroidery machine

An automatic feeding and embroidery machine technology, which is applied to the mechanism of embroidery machines, bobbin winding in embroidery machines, sewing machines, etc., to achieve the effects of improving production efficiency, saving labor, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail by the following examples.

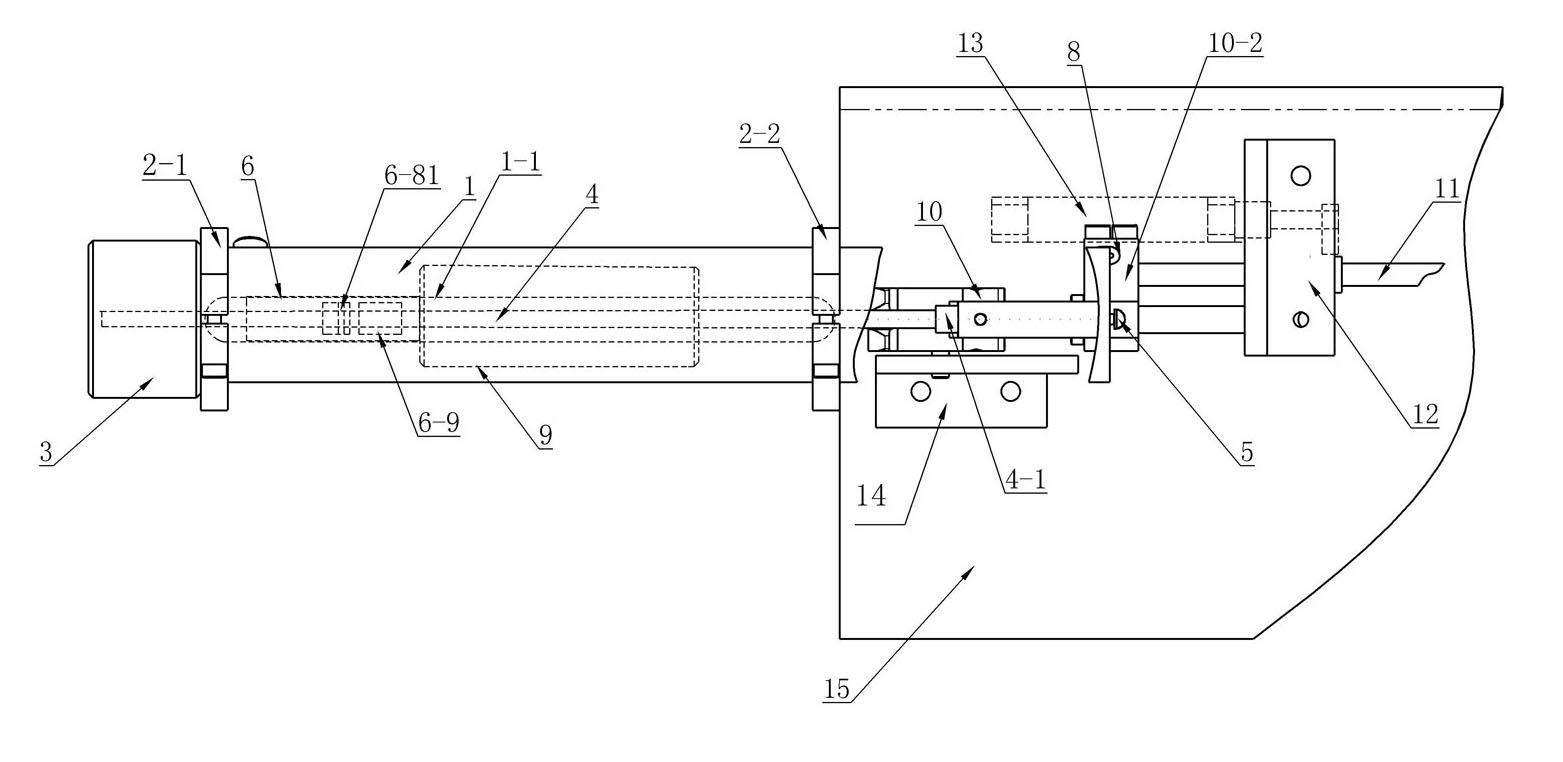

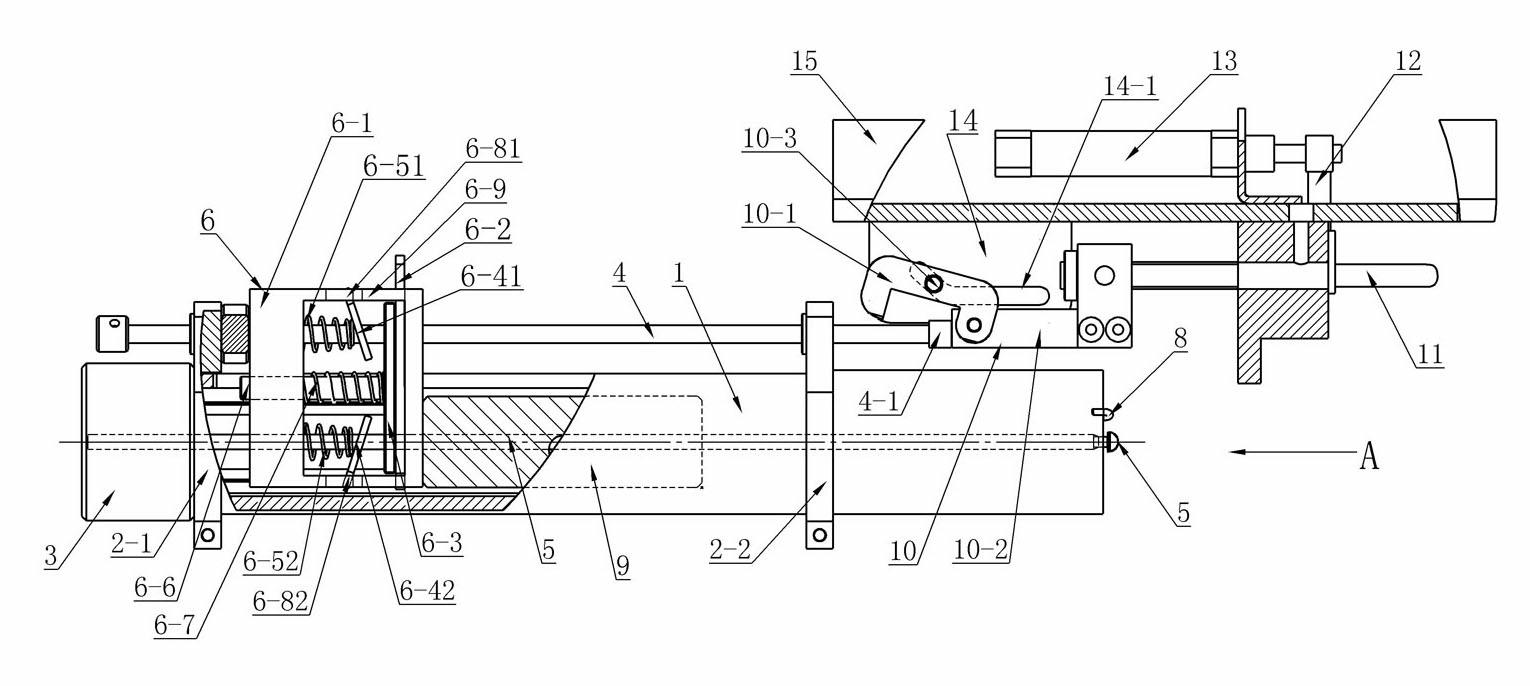

[0029] see figure 1 — image 3As shown, an automatic bobbin feeder for the automatic bobbin thread changing device of a computerized embroidery machine is composed of a bobbin chamber and an automatic pushing mechanism. The whole bobbin chamber is fixed on the mounting plate 15 of the automatic bobbin thread changing device on the computer embroidery machine through the annular mounting frame fastened to the front end of the housing 1, and the automatic pushing mechanism is fixedly arranged on the mounting plate 15 and is in a position with the bobbin chamber. corresponding position.

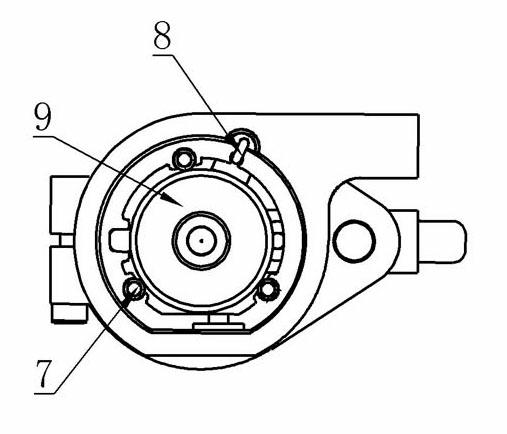

[0030] The bobbin storehouse is made up of housing 1, rear spacer 2-1 and front spacer 2-2, power transmission shaft 4, mandrel 5, feed table 6 and positioning sleeve 9. The housing 1 is quasi-cylindrical with a small part of the side being flat, one end is closed by the end cover 3, and the other open en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com