Supercritical fluid well drilling and completion simulation test device

A supercritical fluid and simulation test technology, which is applied in natural gas drilling and completion, and petroleum fields, can solve problems such as low working pressure or temperature, poor pertinence of measuring equipment, and inability to meet basic conditions, and achieve high evaluation accuracy and distortion small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

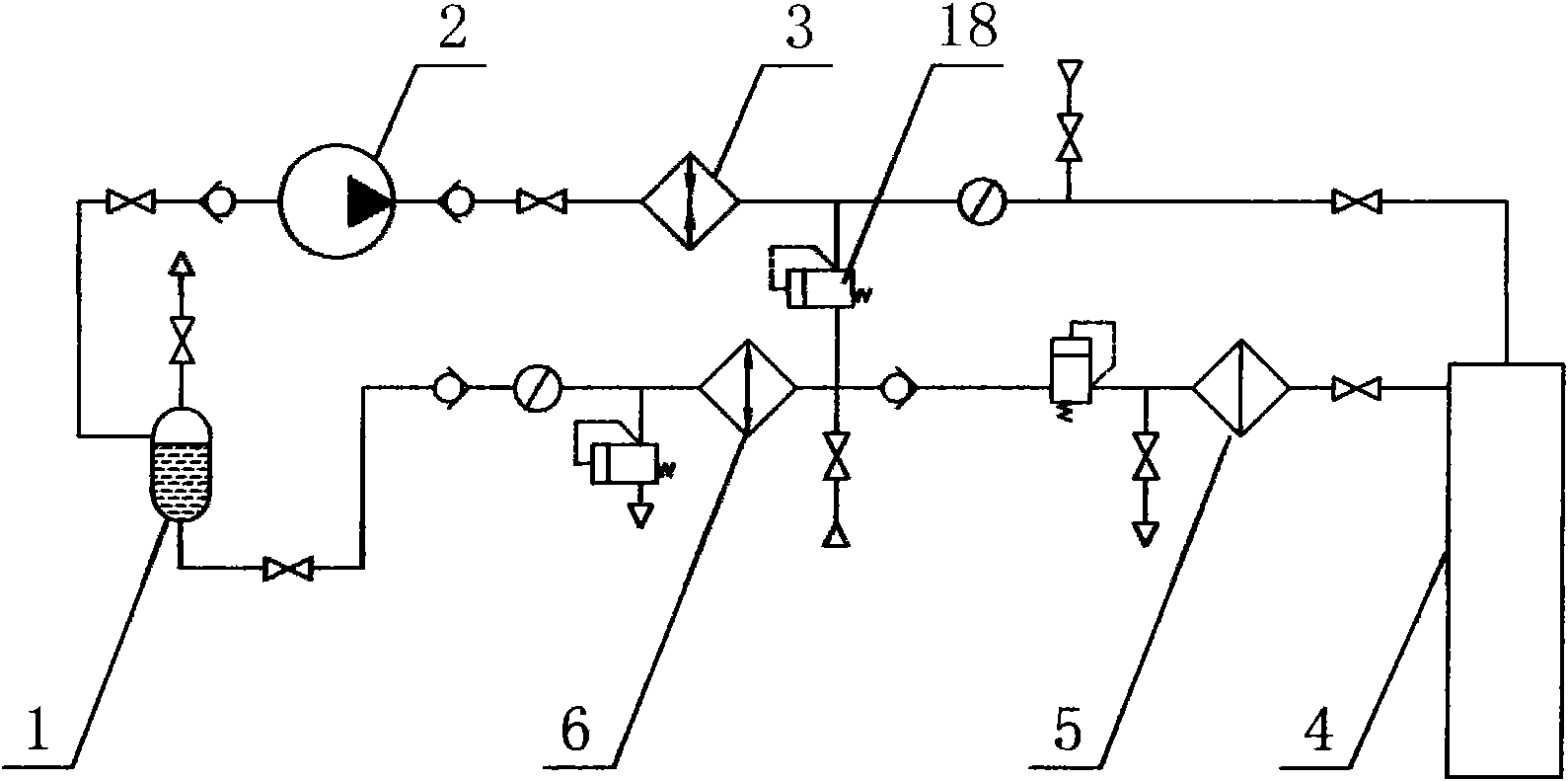

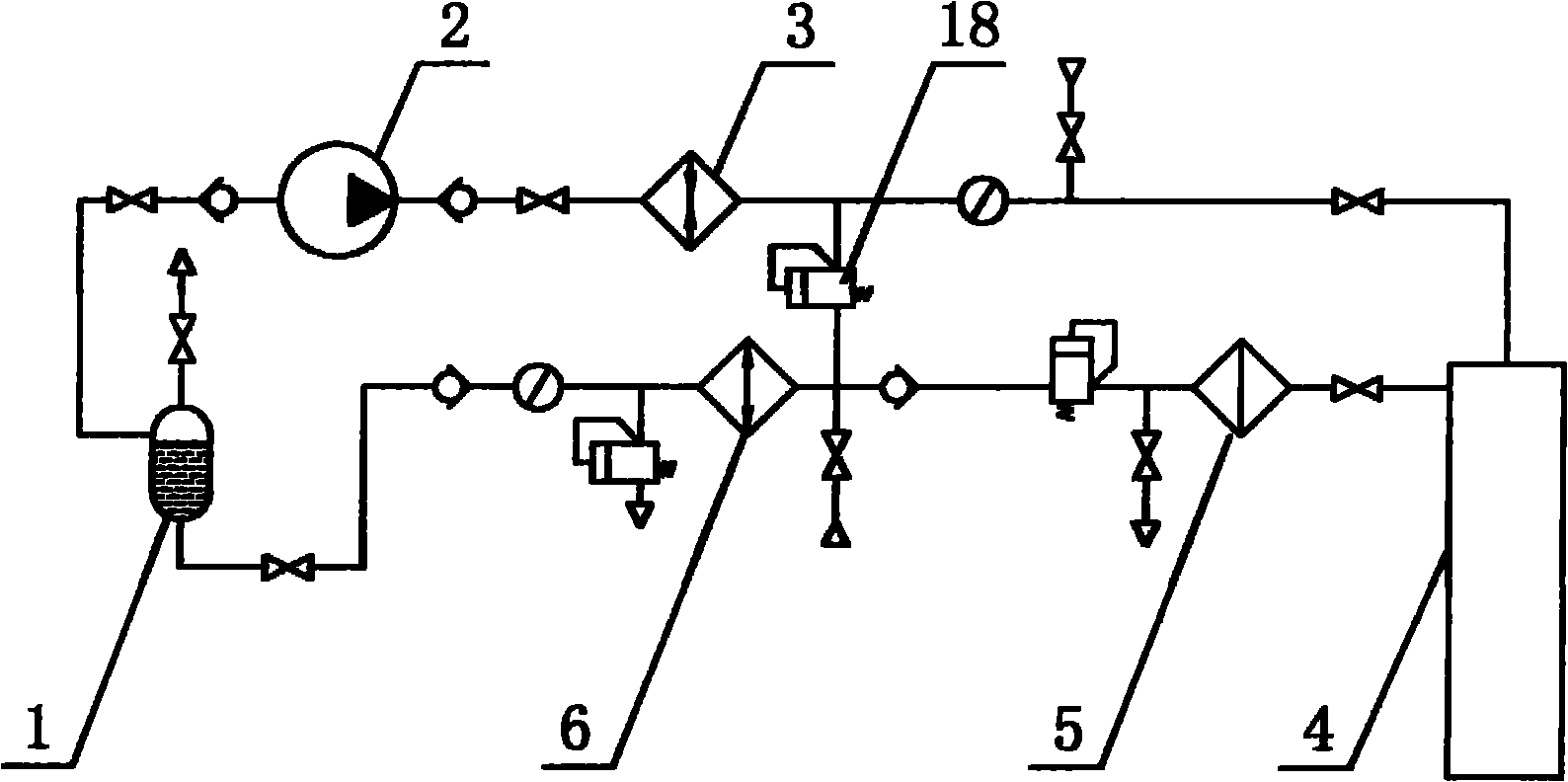

[0015] Such as figure 1 As shown, the supercritical fluid drilling and completion simulation test device includes a main circulation loop, and the main circulation loop is composed of a storage tank 1, a booster pump 2, a heater 3, a drilling and completion simulation test bench 4, a separator 5 and a cooling The devices 6 are connected in sequence through high-pressure pipelines. Wherein, the storage tank 1 is provided with an explosion-proof control valve, and the booster pump 2 is provided with a temperature controller.

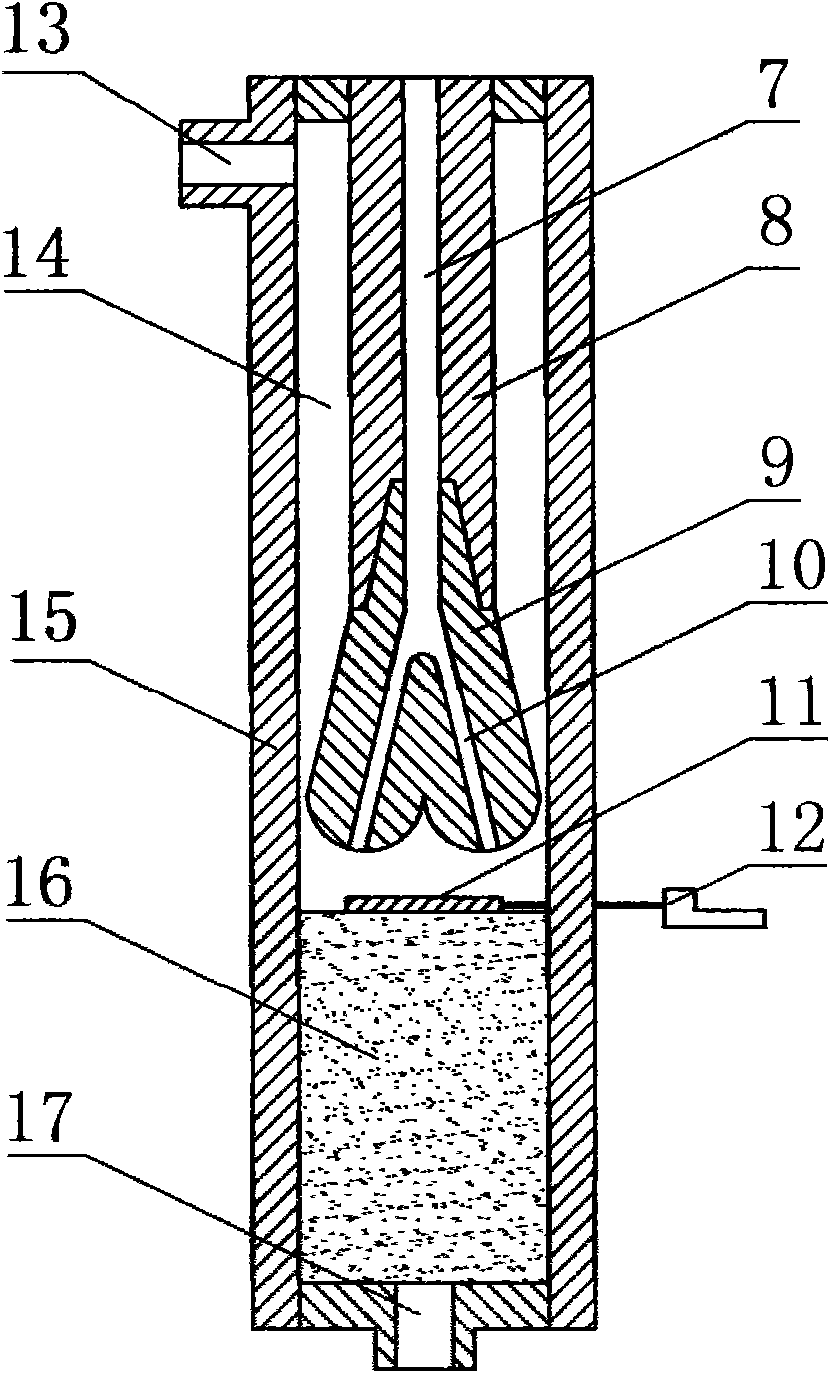

[0016] Such as figure 2 As shown, the drilling and completion simulation test bench 4 includes a wellbore 15, a simulated core 16 is provided at the bottom of the wellbore 15, and a drilling tool is provided above the simulated core 16, and the drilling tool has a hollow A drilling channel for supercritical fluid to flow through, a movable baffle 11 is provided between the simulated core 16 and the drilling tool, and the outside of the wellbore 15 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com