Device for evaluating performance of SCR catalyst for synergistically removing nitric oxide, benzene and methylbenzene

A technology of SCR catalyst and nitric oxide, which is used in measurement devices, chemical analysis using catalysis, material separation, etc., can solve problems such as human health and ecological environment hazards, achieve simple gas distribution, reduce experimental errors, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

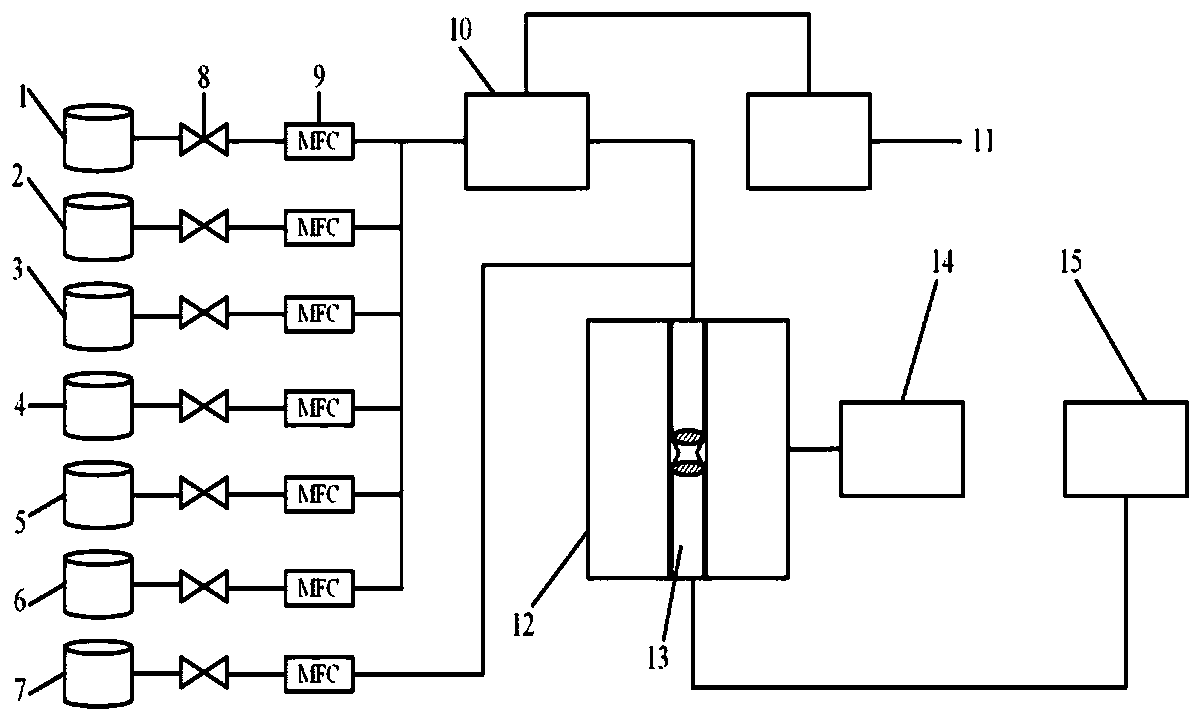

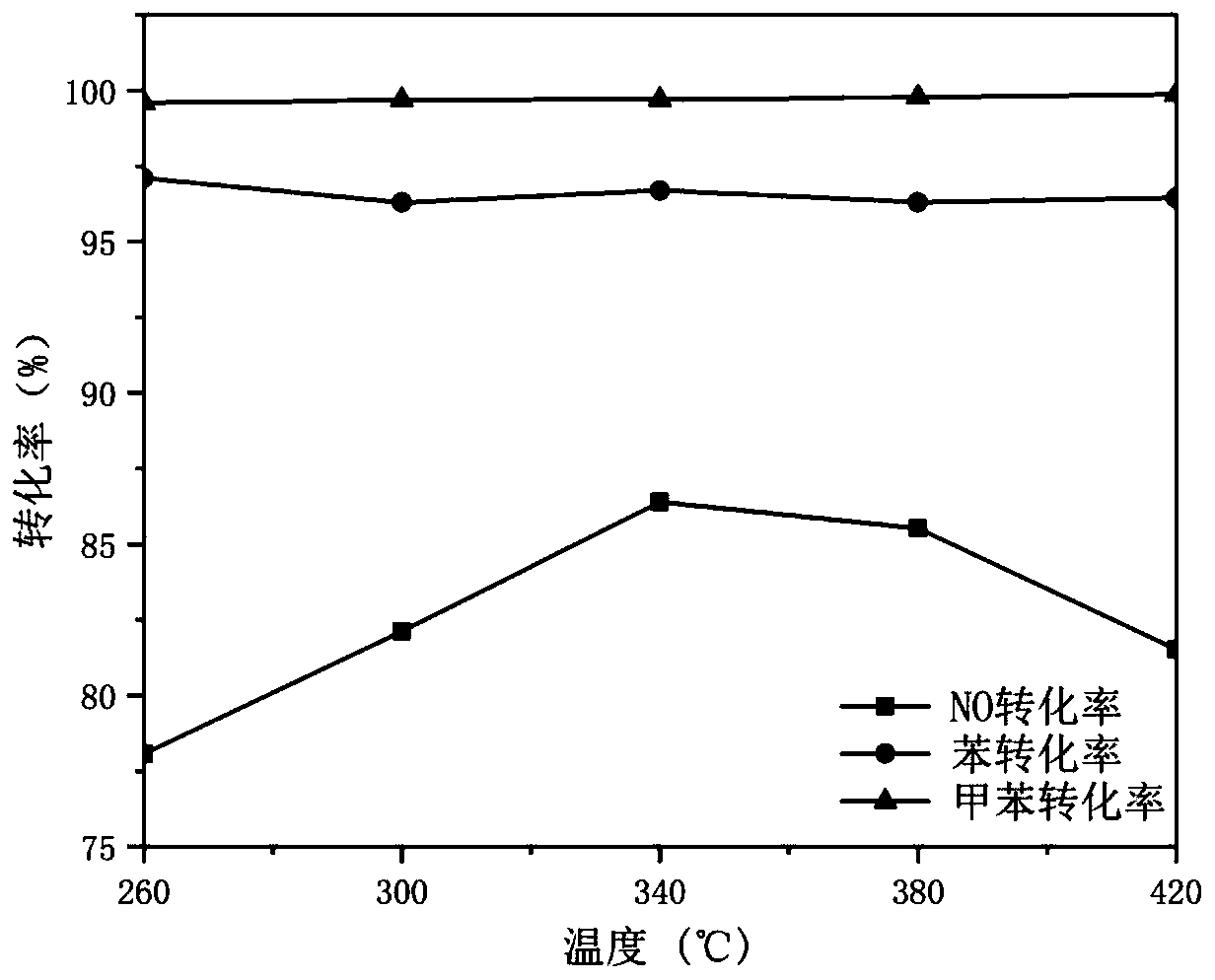

[0037] This embodiment utilizes Cu-doped V 2 o 5 -WO 3 / TiO 2 Catalyst, to evaluate and test the performance of the catalyst to remove NO, benzene and toluene: the simulated flue gas composition is 500ppm NO, 1000ppm SO 2 , 500ppm NH 3 , 100ppm benzene and toluene, 3.33% O 2 , N 2 It is the carrier gas, the gas flow rate is 750mL / min, and the test temperature is 260-420°C. For the specific test device schematic diagram, see figure 1 .

[0038] Weigh 0.1 g of the catalyst, and fix the catalyst on the constriction of the quartz tube 13 with quartz wool.

[0039] NO, SO 2 , NH 3 , benzene and toluene, O 2 and N 2 The flow rates are all controlled by the gas mass flowmeter 8, except for NH 3 In addition, other simulated mixed gases enter the mixed gas tank 10, NH 3 Directly enter the vertical heating furnace 12, the temperature of the gas mixing tank 10 is controlled at 120°C, and the temperature of the vertical heating furnace 12 is controlled at 260~420°C (±1°C).

...

Embodiment 2

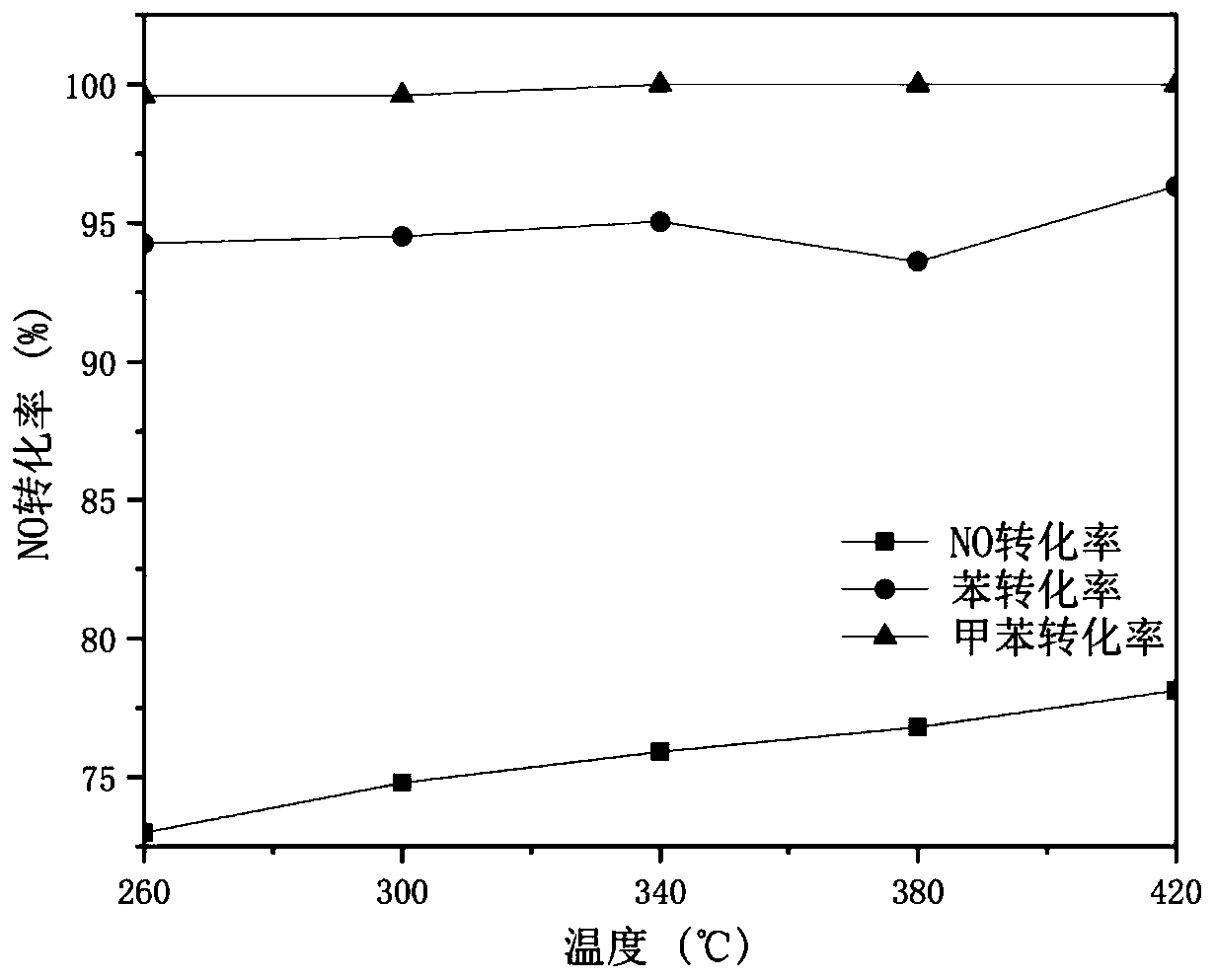

[0046] This embodiment utilizes Co-doped V 2 o 5 -WO 3 / TiO 2 Catalyst, to evaluate and test the performance of the catalyst to remove NO, benzene and toluene: the simulated flue gas composition is 500ppm NO, 1000ppm SO 2 , 500ppm NH 3 , 100ppm benzene and toluene, 3.33% O 2 , N 2 It is the carrier gas, the gas flow rate is 750mL / min, and the test temperature is 260-420°C. For the specific test device schematic diagram, see figure 1 .

[0047] Weigh 0.1 g of the catalyst, and fix the catalyst on the constriction of the quartz tube 13 with quartz wool.

[0048] NO, SO 2 , NH 3 , benzene and toluene, O 2 and N 2 The flow rates are all controlled by the gas mass flowmeter 8, except for NH 3 In addition, other simulated mixed gases enter the mixed gas tank 10, NH 3 Directly enter the vertical heating furnace 12, the temperature of the gas mixing tank 10 is controlled at 120°C, and the temperature of the vertical heating furnace 12 is controlled at 260~420°C (±1°C).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com