Anti-static protector for photographic films

A protector and anti-static technology, used in containers, containers, packaging and other directions to prevent mechanical damage, can solve problems such as affecting film quality, film exposure, shaking, etc., to prevent frictional static electricity, easy to pick and place, simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

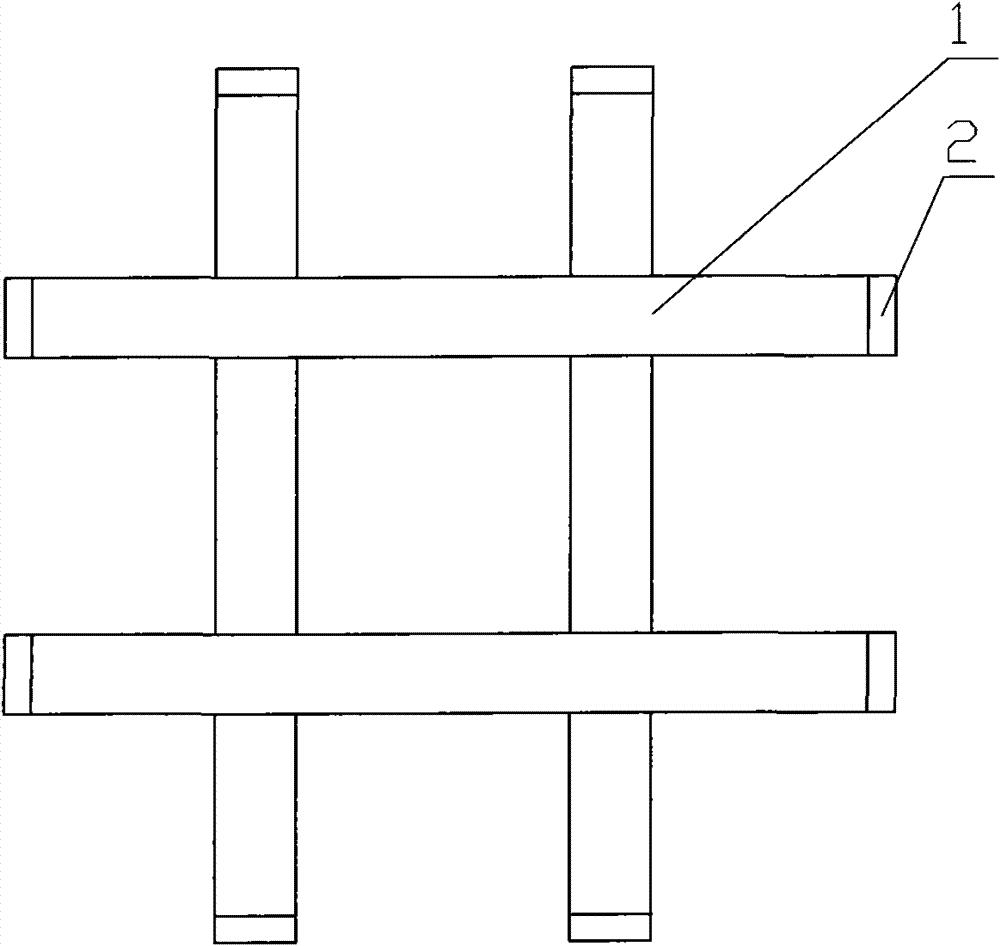

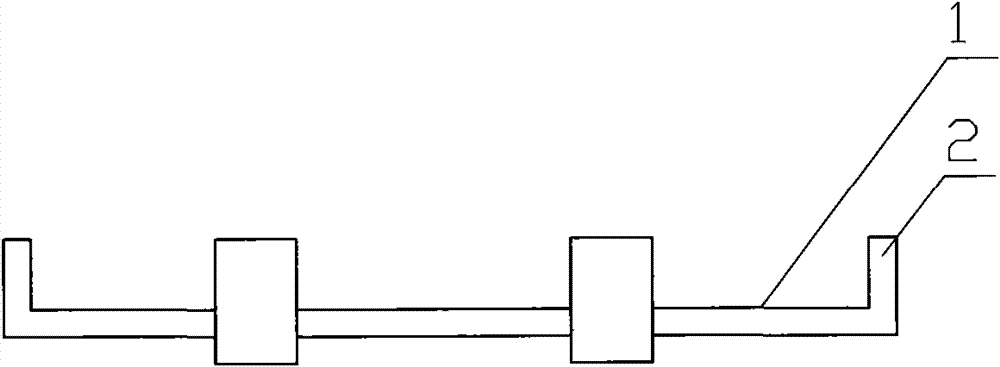

[0010] like figure 1 , figure 2 and image 3 A specific embodiment shown, the protector has a protective side 1 that can be in contact with one side of a plurality of stacked films and is fixed on the protective side 1 and can be stuck on a plurality of stacked films. Protrusions 2 on four sides.

[0011] The protector can have the following structure: it includes four high-density sponge strips bonded into a well-shaped shape, the two ends of all high-density sponge strips are bent to the same side, and the middle well-shaped part of the four high-density sponge strips forms the protection On the side 1 , the bent end of the high-density sponge strip forms the protrusion 2 .

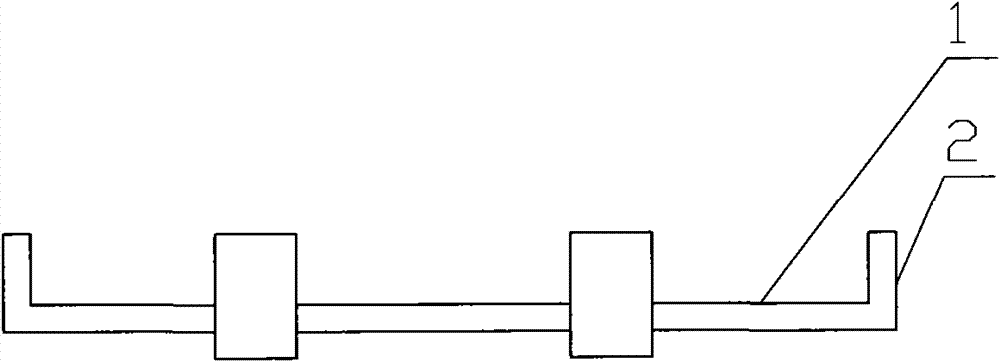

[0012] The protective side 1 of the protector can also be a complete flat plate, and the protrusion 2 can be a square frame fixed to the four sides of the protective side 1 .

[0013] The protector is usually used in conjunction with the film packaging box. The protector is placed in the packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com