A high-performance composite material double-wall oil storage tank and its preparation method

A technology for composite materials and oil storage tanks, which is applied in the field of high-performance composite material double-wall oil storage tanks and its preparation, can solve the problems of poor corrosion resistance of steel tanks, poor antistatic mechanical properties, and short service life. Effects of improving strength and corrosion resistance, improving compressive strength, improving modulus and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

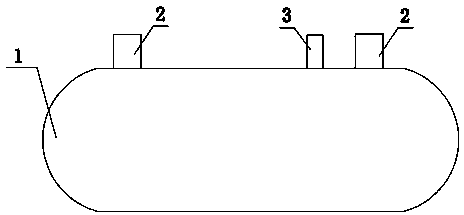

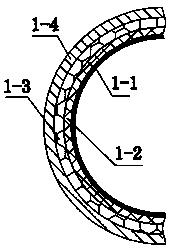

[0028] Such as figure 1 As shown, a high-performance composite material double-walled oil storage tank includes a tank body 1, an operation manhole 2 and an online monitoring well 3 are arranged on the tank body 1, and carbon fiber fabrics are arranged on the inner wall of the inner tank body layer 1-2 Composite formed lining layer 1-1.

[0029] There is a gap between the inner tank layer 1-2 and the outer tank layer 1-4, and an online monitoring structure layer 1-3 formed by glass fiber three-dimensional fabric is arranged in the gap, and the online monitoring structure layer 1-3 is hollow structure.

[0030] The inner tank body layer 1-2 is formed by compounding glass fiber, and the outer tank body layer 1-4 is formed by compounding carbon fiber or / and glass fiber.

[0031] It can be drawn from the above that the tank body 1 of the present invention has a four-layer structure, and the tank body 1 is respectively from the inside to the outside: the first layer is an inner l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com