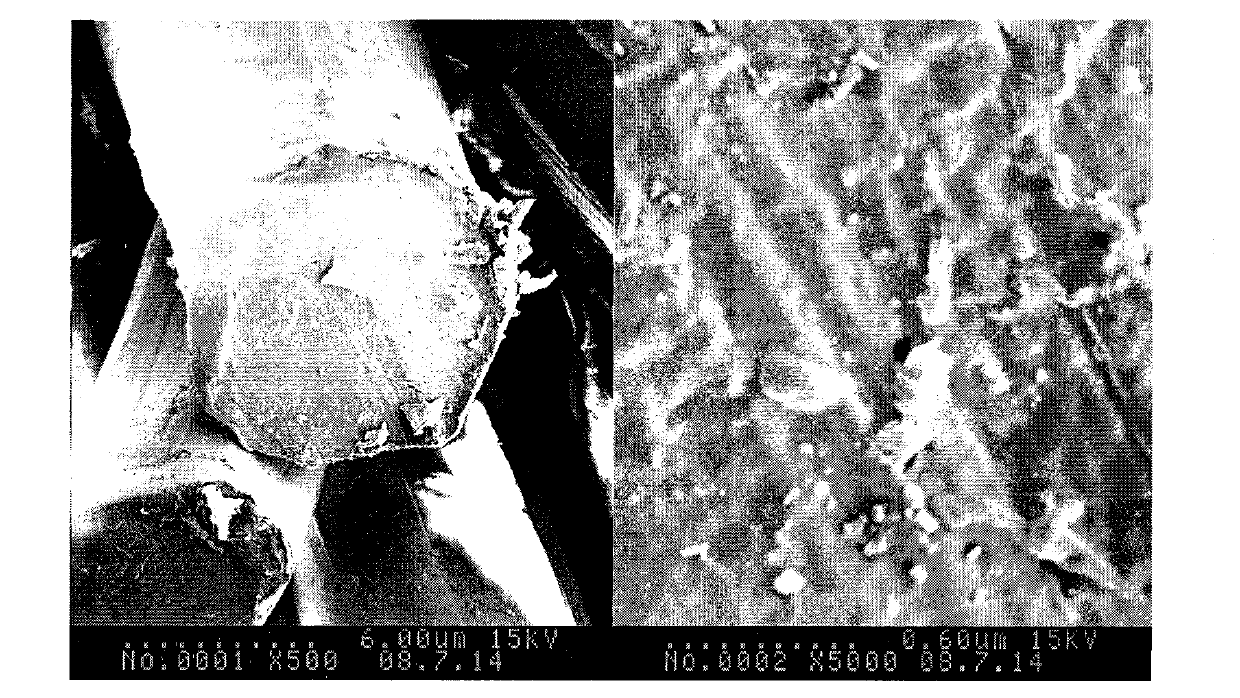

Plasma nano titanic oxide/polypropylene/polylactic acid and preparation method thereof

A nano-titanium dioxide and plasma technology, which is applied in the direction of conjugated synthetic polymer artificial filaments, etc., can solve the problems of poor compatibility and achieve the effects of improved dispersion, unchanged internal phase structure, and high fiber-forming strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

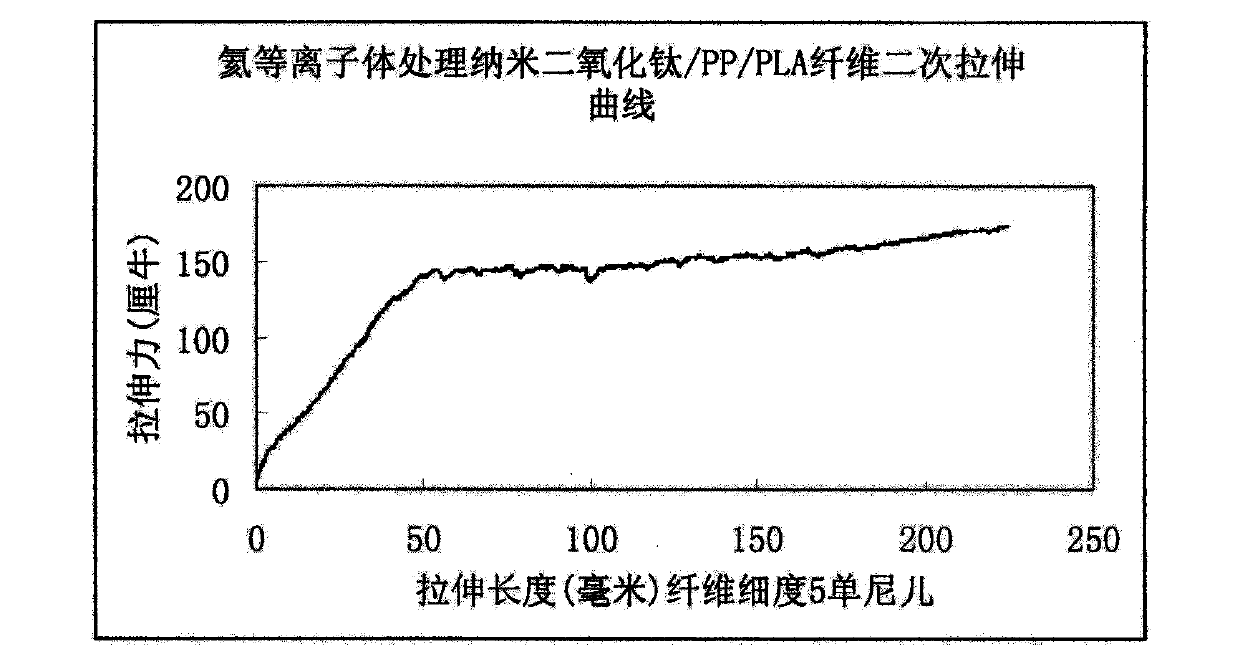

Method used

Image

Examples

Embodiment

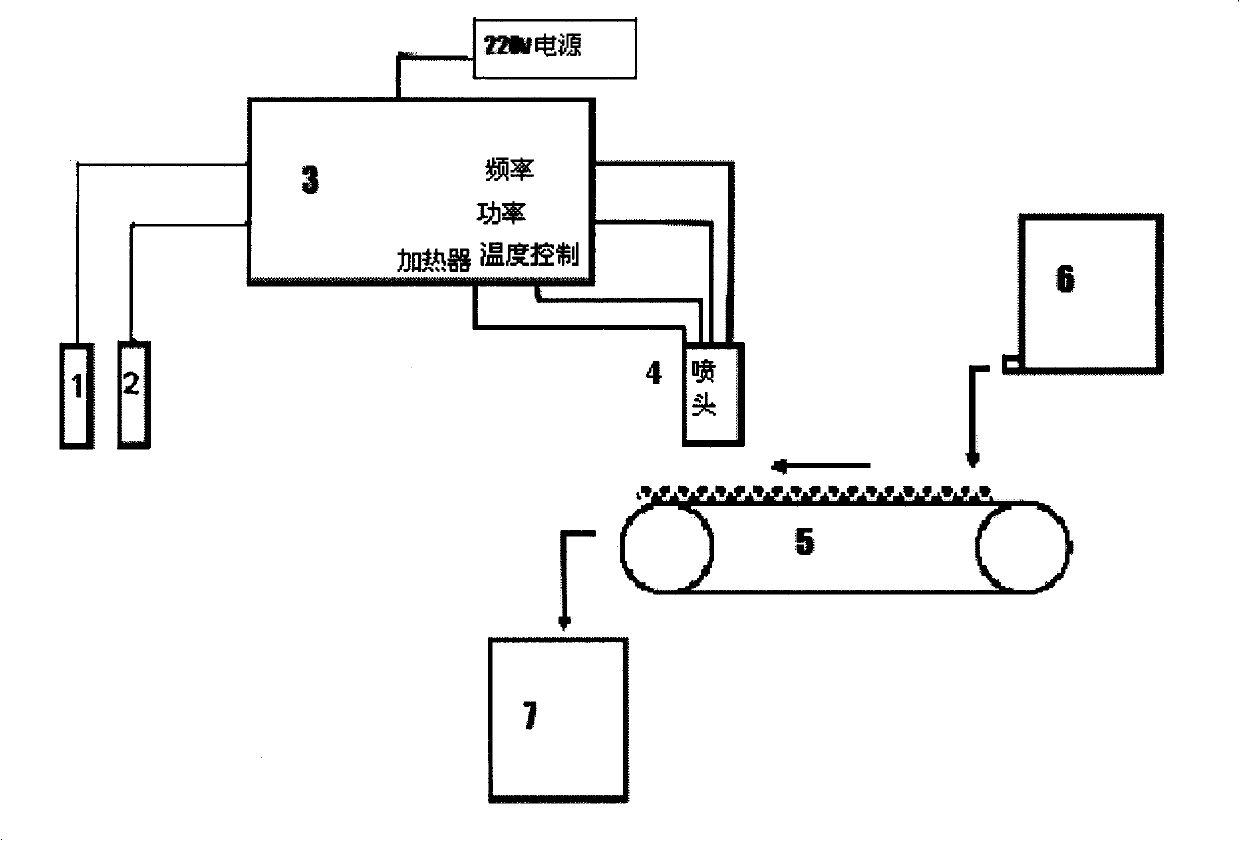

[0024] (1) Take a certain amount of commercial titanium dioxide nanopowder and put it on the special transmission device of the plasma processing equipment. Schematic such as image 3 (or a channel for adding a plasma nozzle), the container or carrier is placed within a specific distance of 2 cm below the nozzle of the normal pressure\normal temperature plasma spray device (the design of the nozzle part of the channel is based on specific requirements), and the thickness of the nanopowder laying Lay it according to the thickness of 5 mm. Under the premise of turning on the plasma at normal pressure and room temperature, the container or carrier moves at a specific speed. Realize that nano-titanium oxide powder can be obtained under helium plasma atmosphere, power 40 watts and 5 seconds. deal with.

[0025] (2) Mix the above-mentioned inorganic solid-phase substance with polypropylene / polylactic acid powder or chips in a mass ratio of 0.1-20% with a twin-screw extruder, and me...

Embodiment 2

[0028] (1) Take a certain amount of commercial titanium dioxide nanopowder and put it on the special transmission device of the plasma processing equipment. Schematic such as image 3 (or a channel for adding a plasma nozzle), the container or carrier is placed within a specific distance of 2 cm below the nozzle of the normal pressure\normal temperature plasma jet device (the design of the nozzle part of the channel is based on specific requirements), and the thickness of the nanopowder laying Lay it according to the thickness of 5 mm. Under the premise of turning on the normal pressure and room temperature plasma, the container or carrier moves at a specific speed. Realize that the nano-titanium oxide powder can be processed in an oxygen plasma atmosphere with a power of 40 watts and 5 seconds. .

[0029] (2) Mix the above-mentioned inorganic solid-phase substance with polypropylene / polylactic acid powder or chips in a mass ratio of 0.1-20% with a twin-screw extruder, and me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com