Weaving edge forming device of a rubber strengthening textile weaving loom

A loom and rubber technology is applied in the field of weaving edge forming devices, which can solve the problems of high cost of the device, complicated device structure, and inability to stably form the weaving edge shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

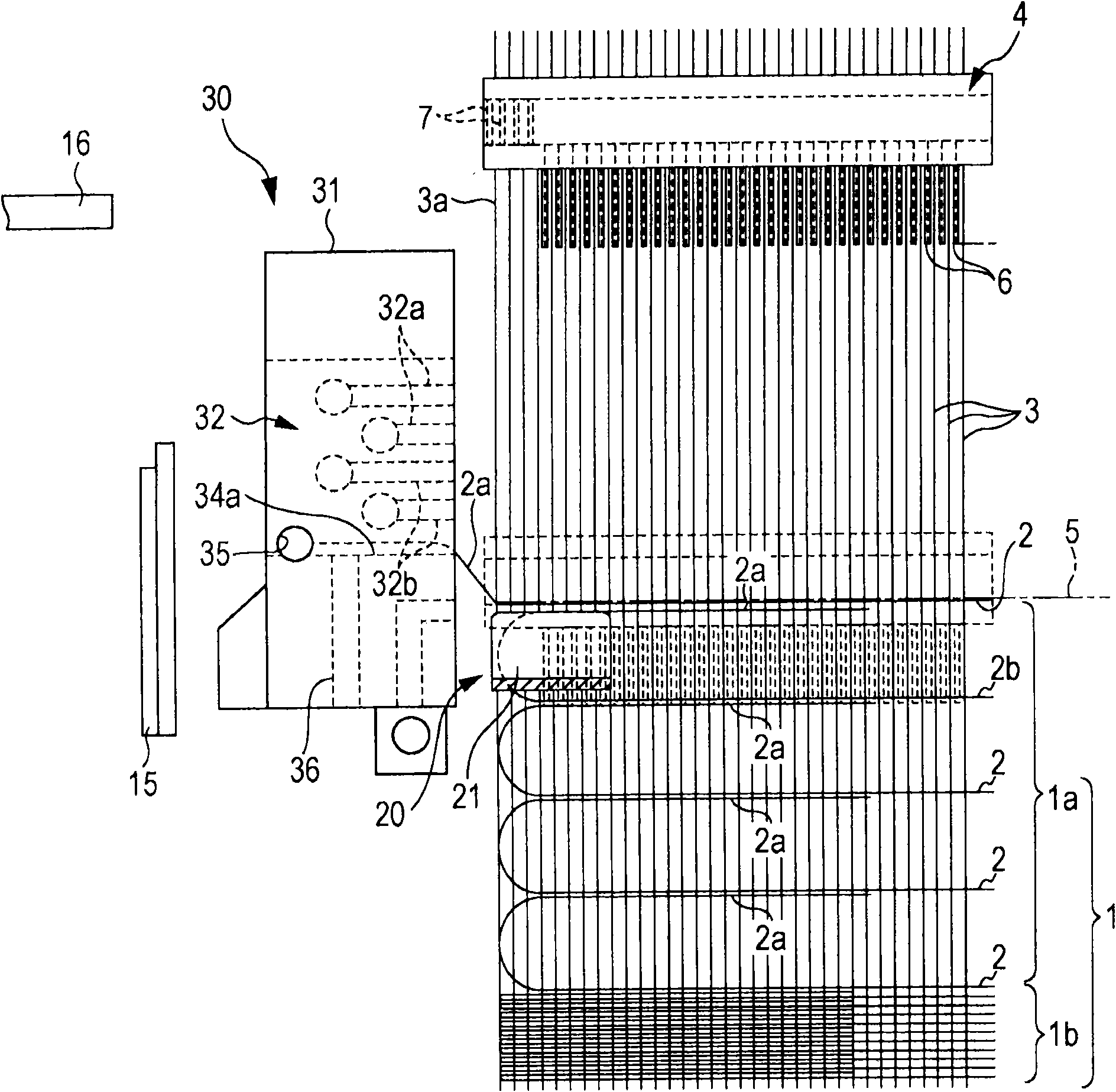

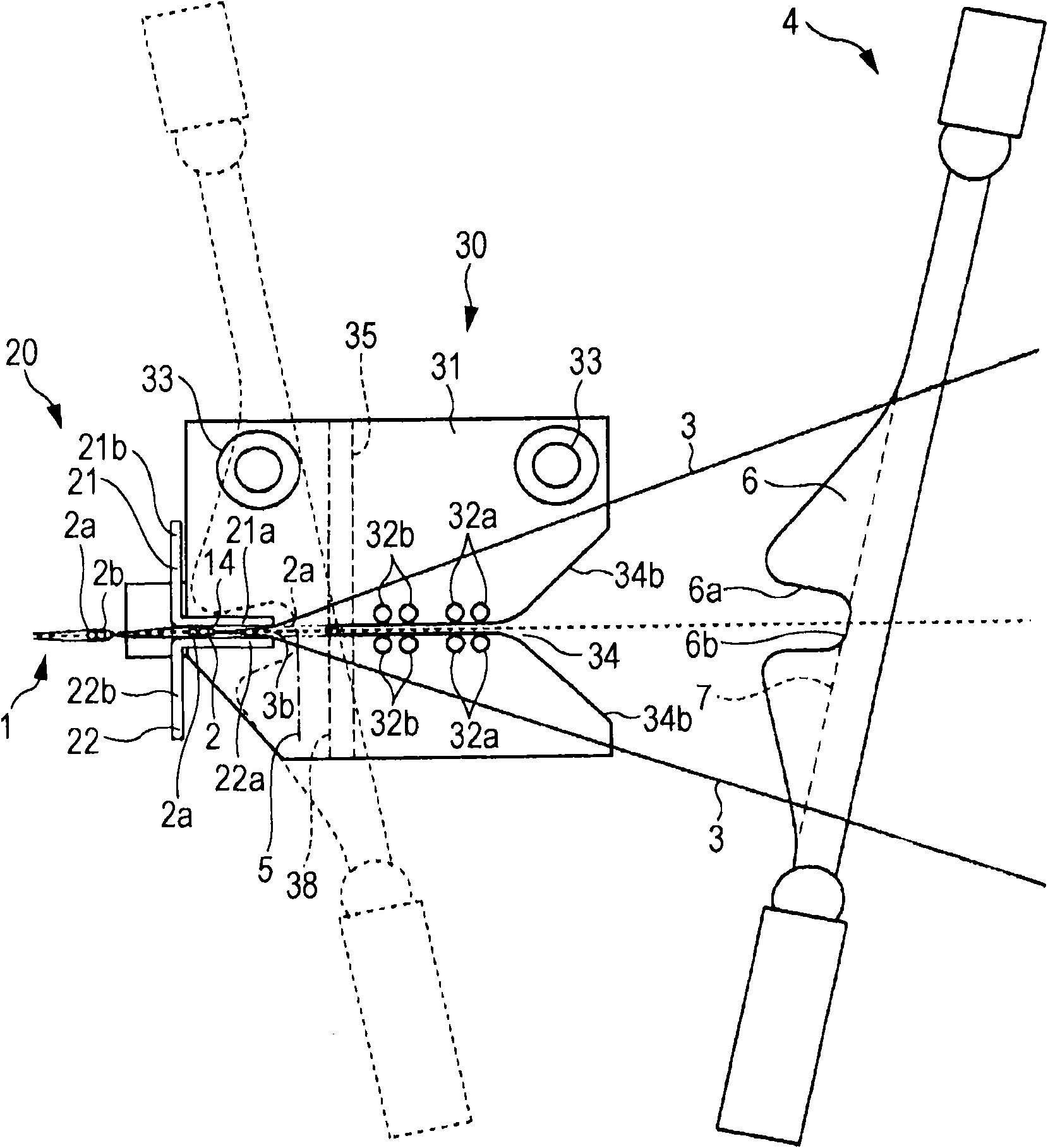

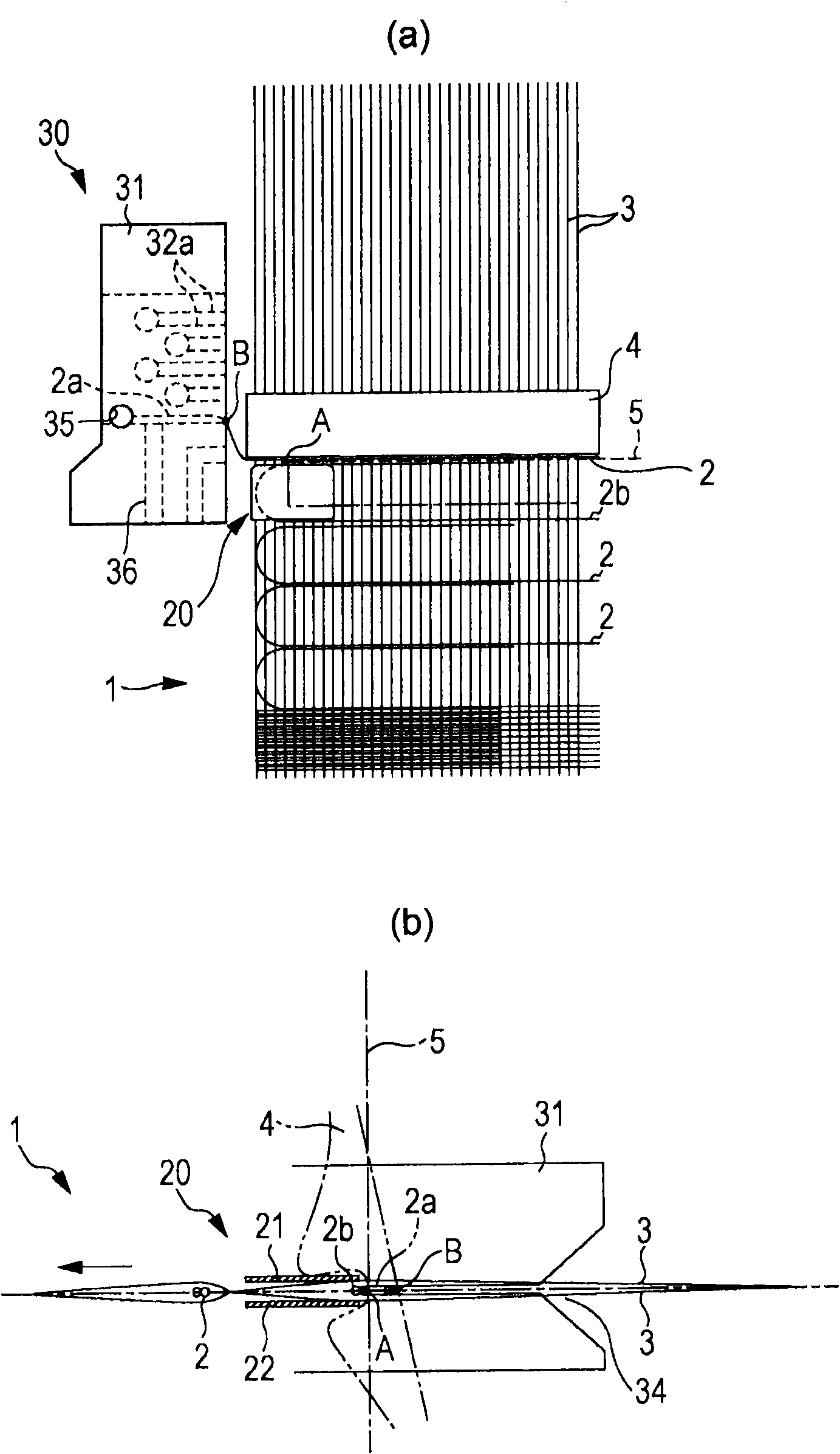

[0094] refer to Figure 1 to Figure 6 One embodiment of the weaving edge forming device of the present invention will be described. Figure 1 to Figure 6 The example shown is an example in which the present invention is applied to a shuttleless loom for weaving one of the rubber-reinforcing fabrics 1, that is, a tire cord fabric.

[0095] The so-called tire cord fabric refers to the rubber reinforcing fabric used to manufacture the carcass layer as the skeleton of the rubber tire, such as figure 1 As shown, it includes a cord weave portion 1a having a very coarse weft density and a plain weave portion 1b having a weft density denser than the cord weave portion, two weft portions having greatly different weft densities from each other. A rubber material is applied to the carcass portion 1a of the tire carcass 1, thereby manufacturing a carcass ply.

[0096] Figure 1 to Figure 6 The shown weaving edge forming device 30 is an air-jet type weaving edge forming device, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com