Method for processing bush plate by common internal grinding machine and tool fixture

A technology for internal grinding machines and tooling fixtures, applied in the field of tooling fixtures, can solve problems such as low output and unsatisfactory production, and achieve the effects of improving work efficiency, reducing the cost of grinding tools, and reducing the cost of equipment and grinding tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

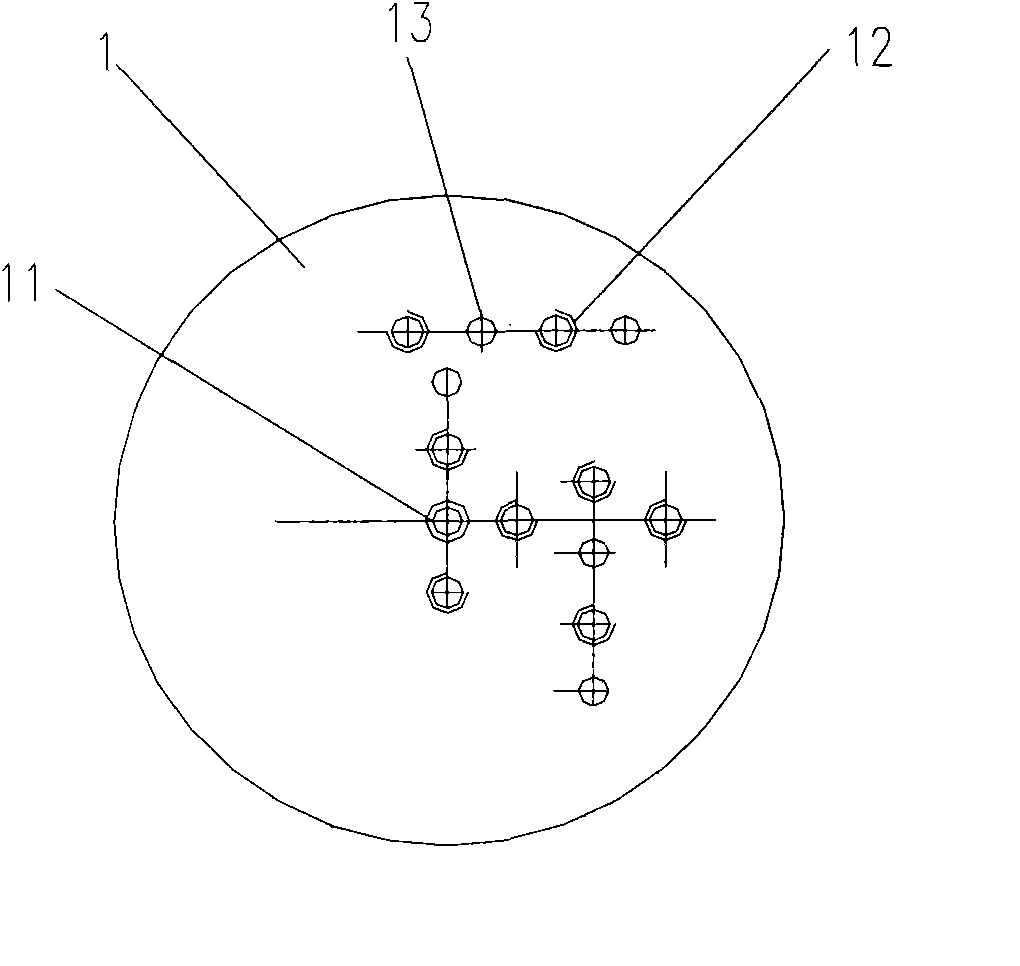

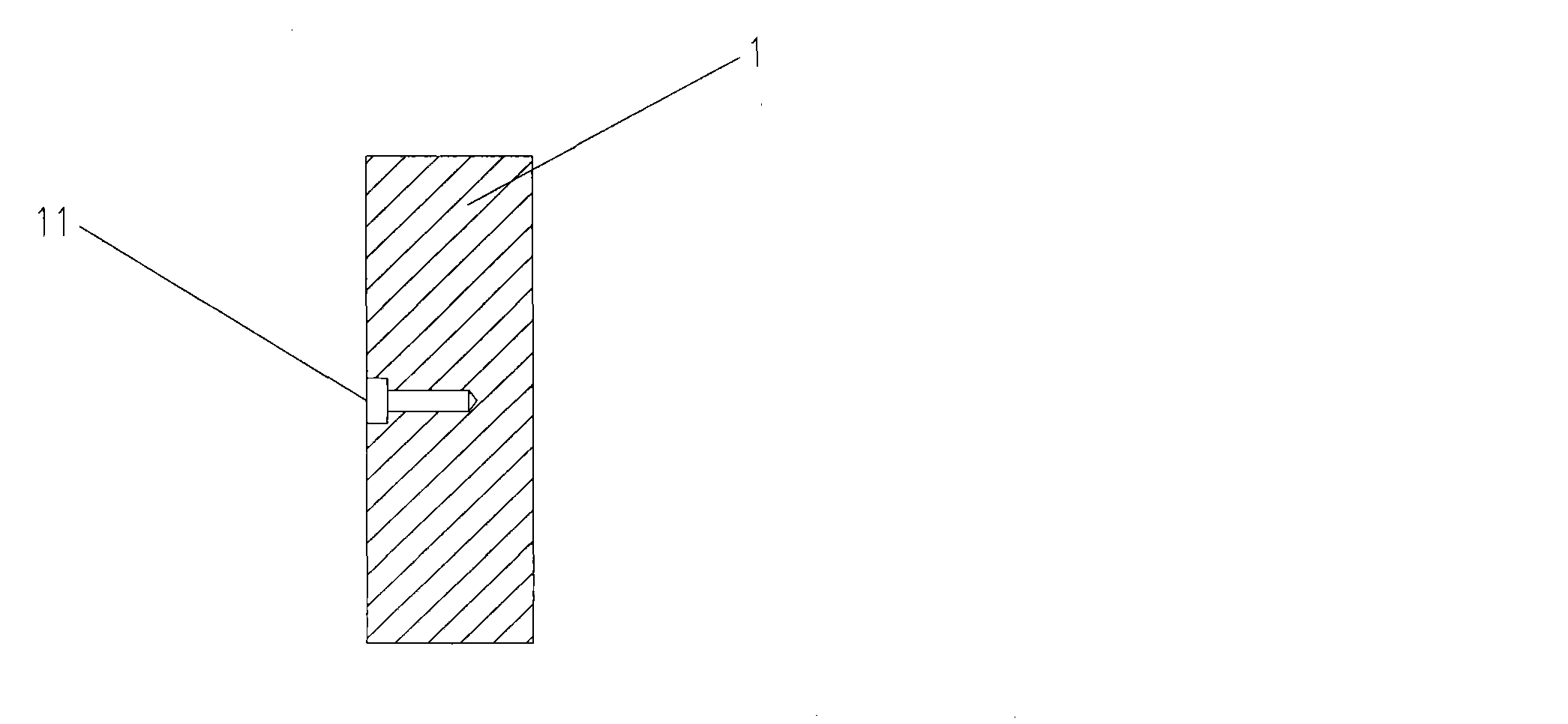

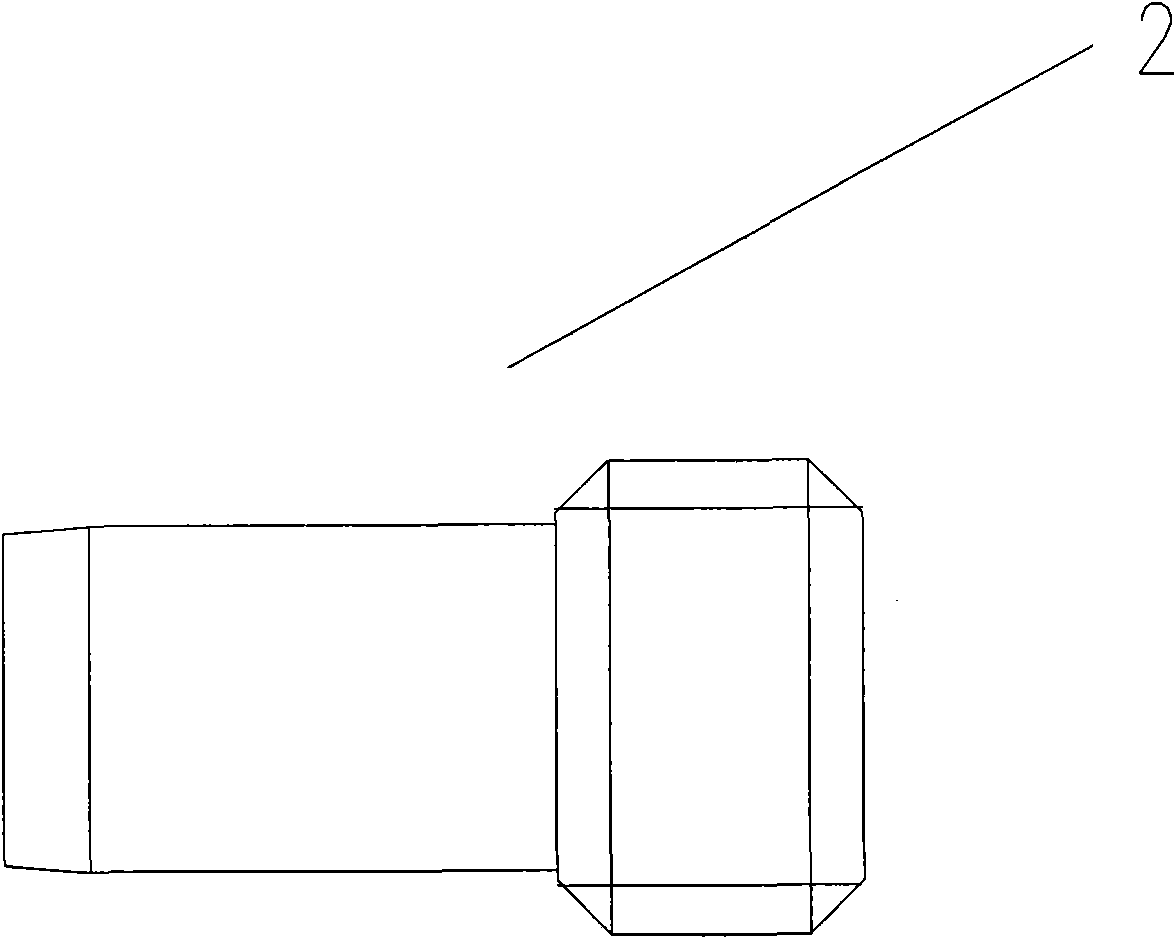

[0029] Figure 1 to Figure 5 As shown, the common internal grinder tooling fixture used for processing the nozzle hole drilling template of the present invention includes a fixture seat 1 and a positioning pin 2, wherein the fixture seat 1 is a disc-shaped structure, and the center of the fixture seat 1 is provided with a hole for matching the grinding machine. Process the step hole 11 of the drill template 4, and the fixture seat is provided with corresponding positioning pin holes 13 and pressing screw holes 12 according to the hole distances of the drill template 4, which are used to position or fix the drill template 4, and the drill template 4 passes through the positioning pins 2 is positioned so as to be fixed on the end face of the fixture seat 1 for processing. Each positioning hole on the drilling template 4 is processed through 4 times of clamping respectively, wherein the accuracy of the positioning pin hole 13 on the fixture seat is about 1 / 3 higher than that of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com