Hermetic rotary compressor base frame

A rotary compressor, sealed technology, used in rotary piston/swing piston pump components, mechanical equipment, machines/engines, etc. Noise, high frequency noise removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

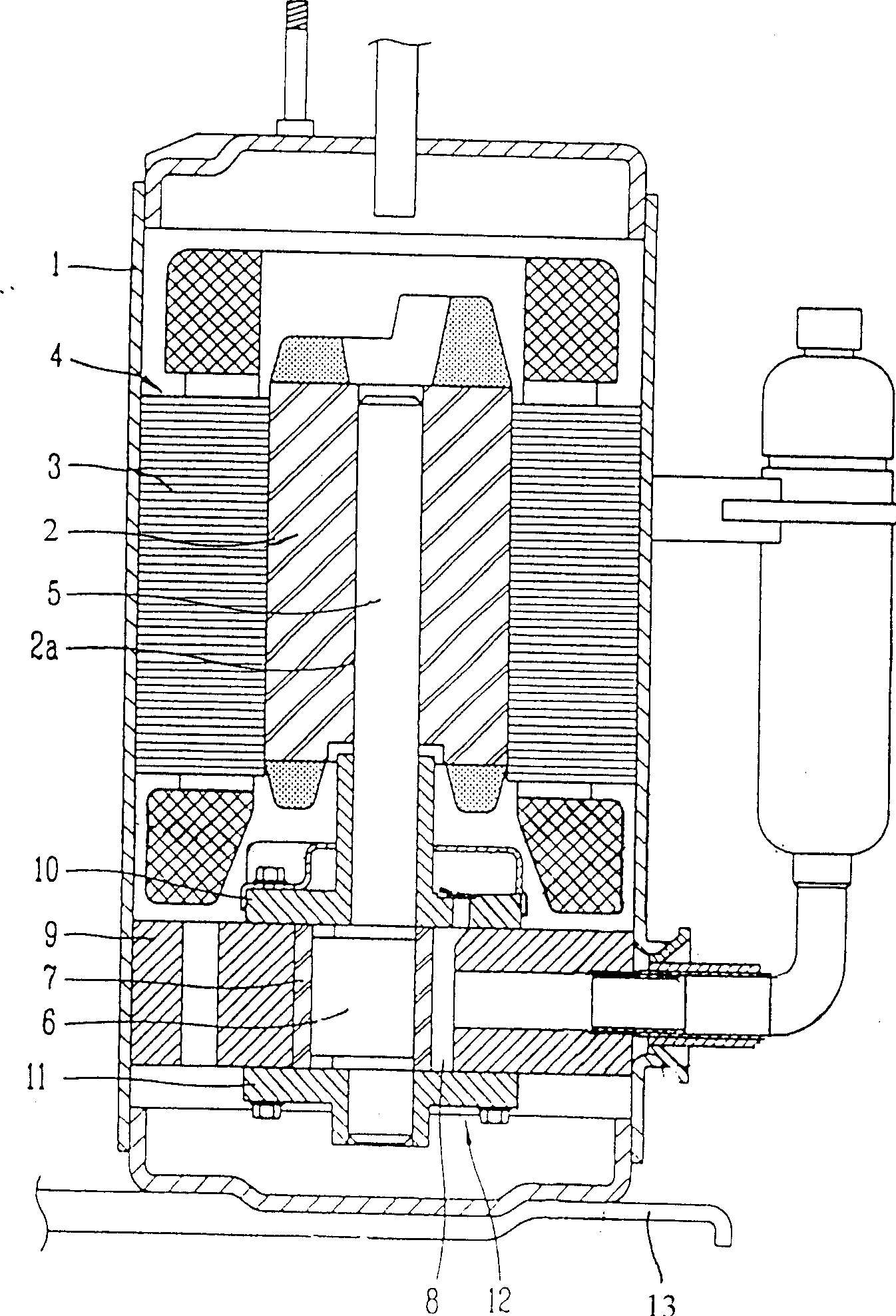

[0017] Hereinafter, the present invention will be described in detail with reference to the drawings and embodiments: the base of the sealed rotary compressor of the present invention, the structure of the sealed rotary compressor is as follows: figure 1 As shown, it includes: a sealed housing 1, a motor 4 composed of a rotor 2 and a stator 3; a rotating shaft 5 is inserted into the shaft hole 2a in the center of the rotor, an eccentric part 6 is provided at the lower end of the rotating shaft, and a piston 7 is provided on the outside of the rotating shaft. In order to form the compression space 8, a compression mechanism 12 composed of a cylinder 9 and upper and lower bearings 10, 11 is installed; the bottom of the sealed casing is connected to the base 13.

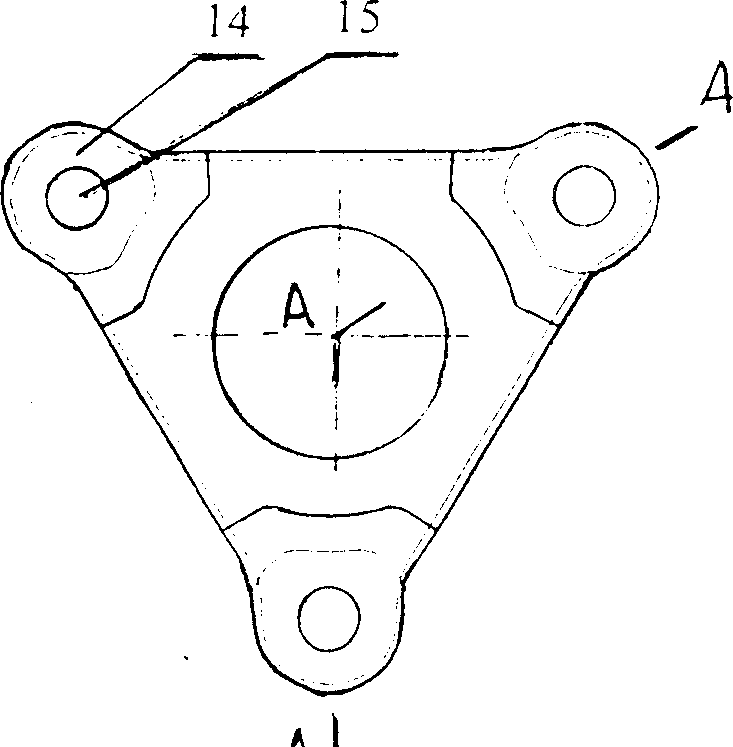

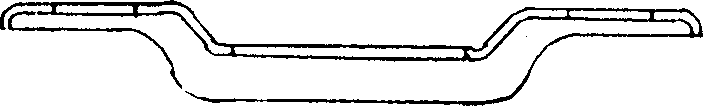

[0018] Such as Figure 4 , Figure 5 As shown, the base is composed of two planes with an open loop in cross section, and the two planes are triangular in shape.

[0019] Corresponding connecting holes 16 are provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com