Platform for measuring average arc force of superaudio-frequency pulse TIG (Tungsten Inert Gas) welding

A technology of argon tungsten arc welding and measuring platform, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low output current switching rate, small cross-sectional elongation, and current zero-crossing dead zone, etc., to achieve guaranteed Effects of Accuracy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

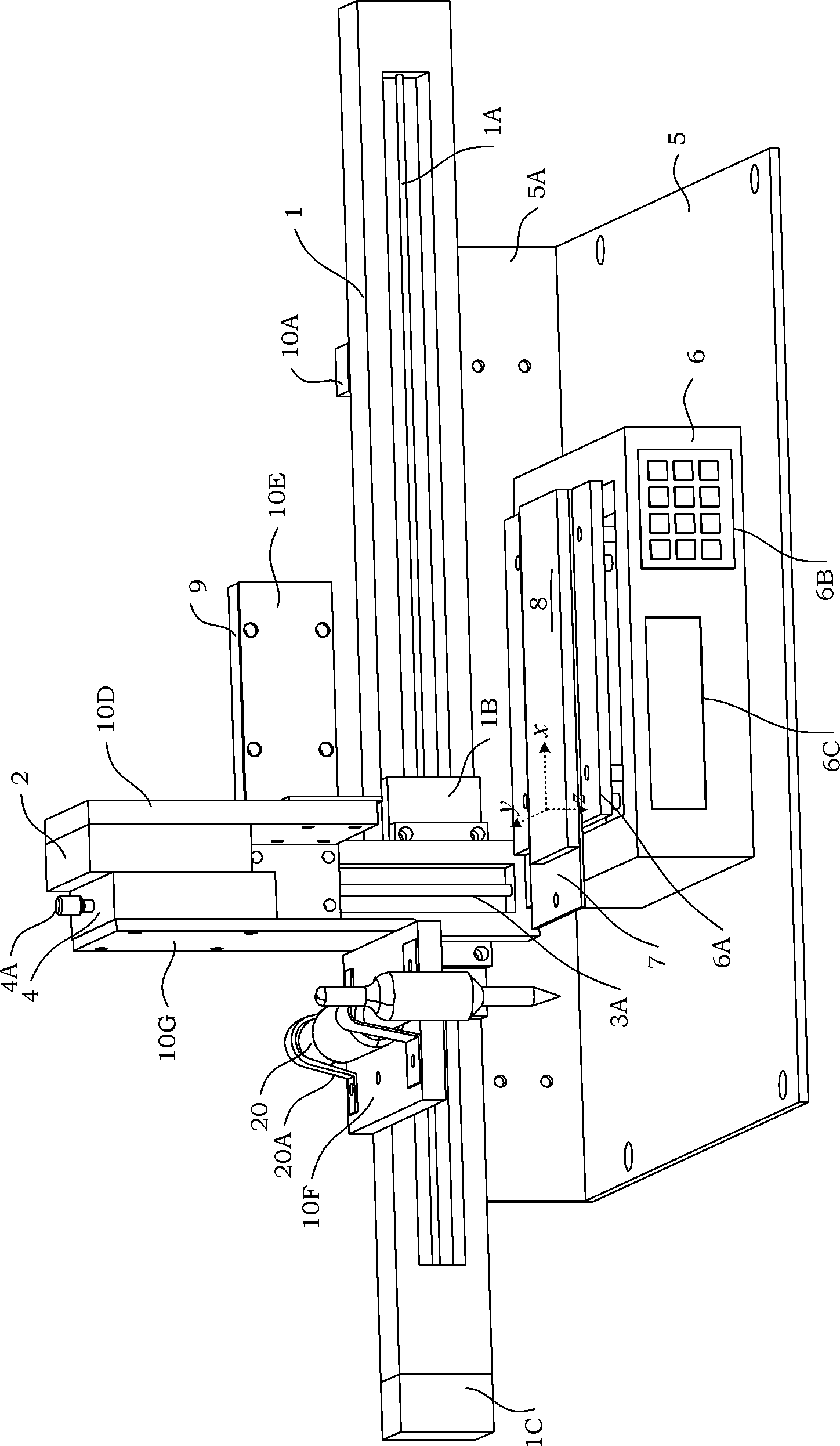

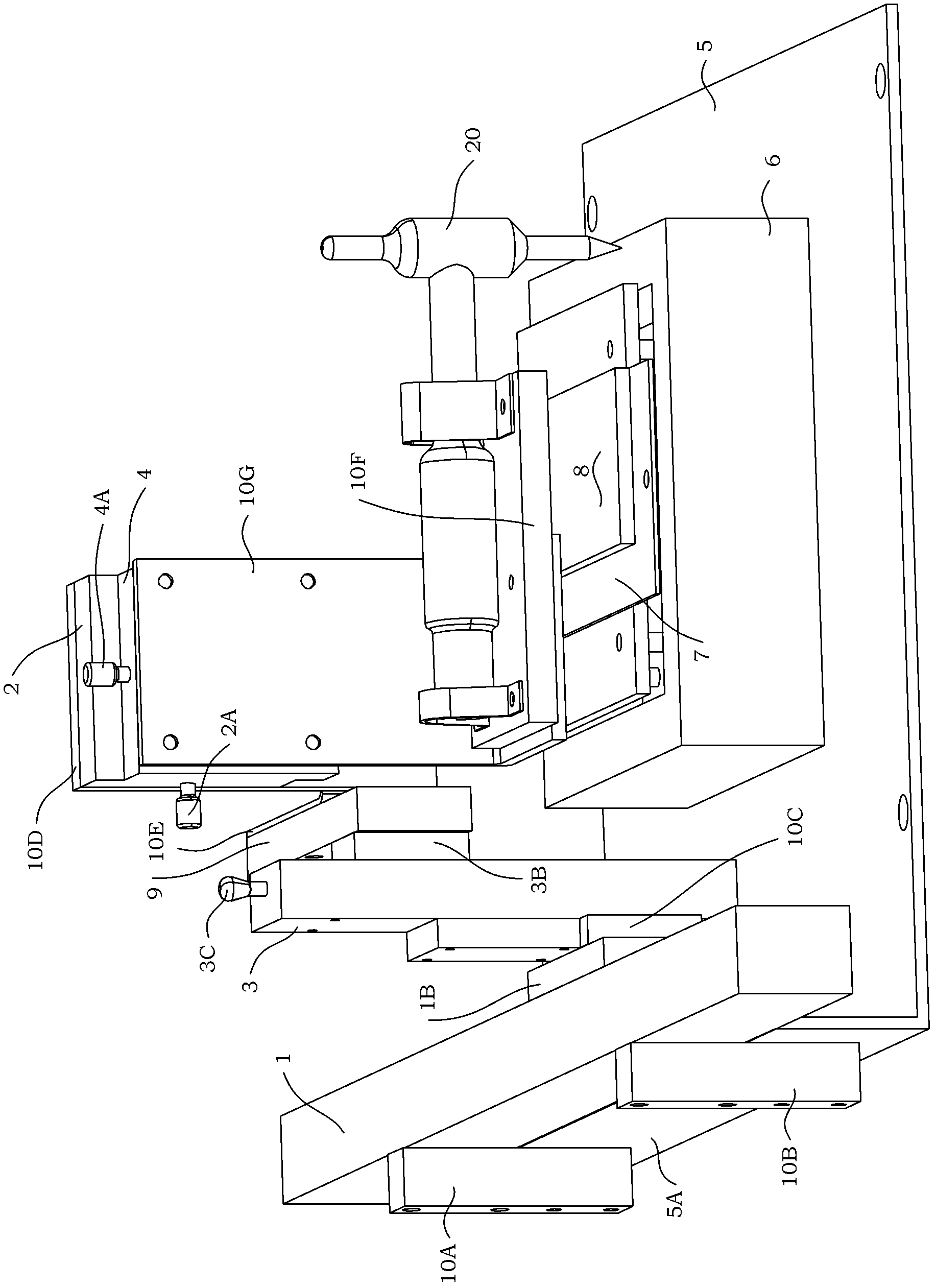

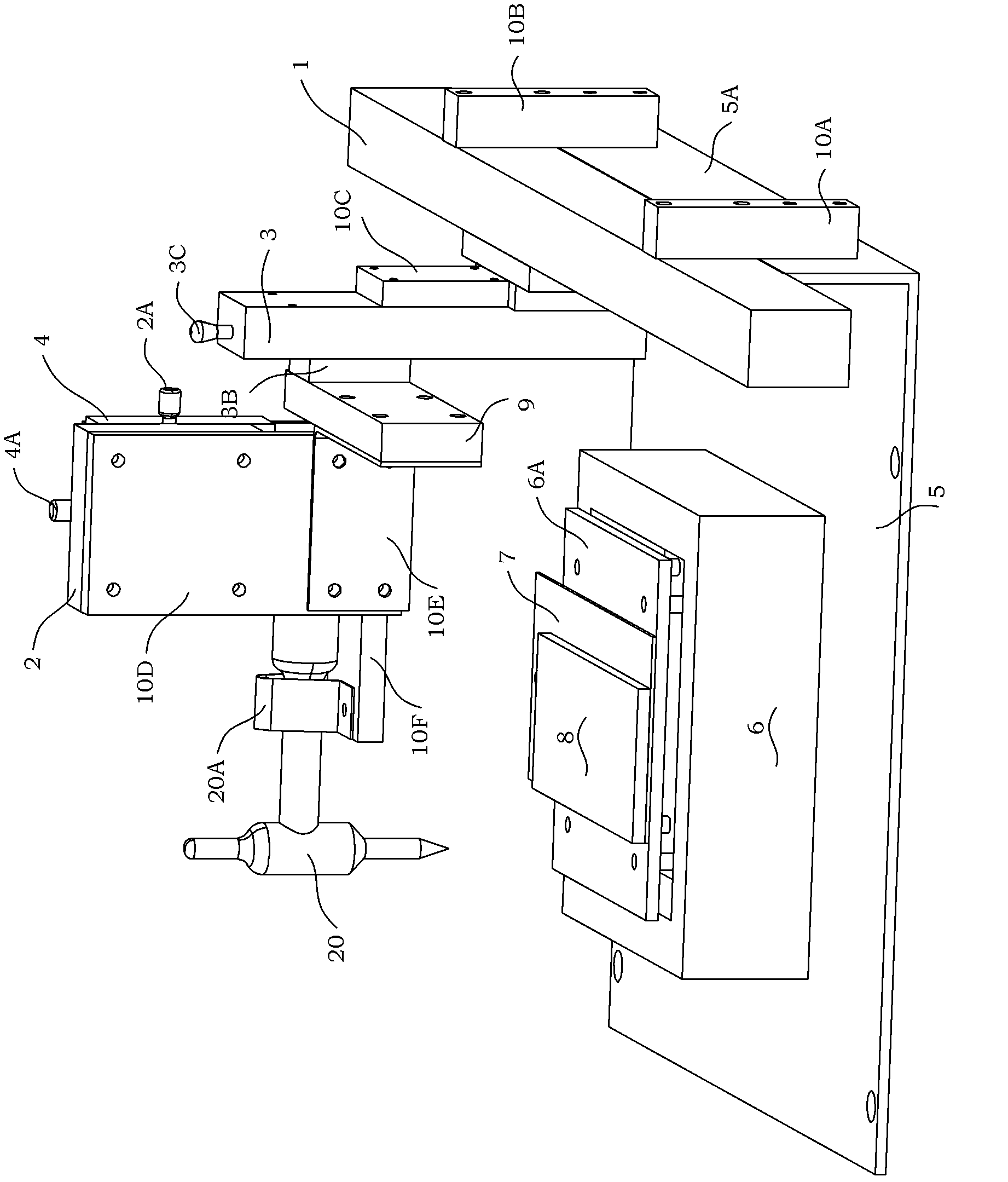

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] see figure 1 , figure 2 , image 3 As shown, a kind of super-audio frequency pulse TIG welding average arc force measurement platform of the present invention, this measurement platform includes welding torch 20, X direction slide table 1, Y direction slide table 2, Z direction rough adjustment slide table 3, Z direction fine adjustment Sliding table 4, processing platform 5, load cell 6, counterweight 9, and a plurality of supporting connecting plates for supporting and connecting.

[0023] The welding torch 20 is mounted on the F-support connector 10F and fixed by two locks 20A.

[0024] In the present invention, in order to ensure the stability of the welding torch 20 in the working state, the weight of the welding torch 20 is adapted to the weight body 9 (the weight body 9 is installed on the E support connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com