Direction-changing conveying device for filter rods

A conveying system and filter rod technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as troubles, low efficiency of conveying and stacking, time-consuming and labor-intensive problems, and achieve reasonable structure, high conveying efficiency and reliable conveying sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

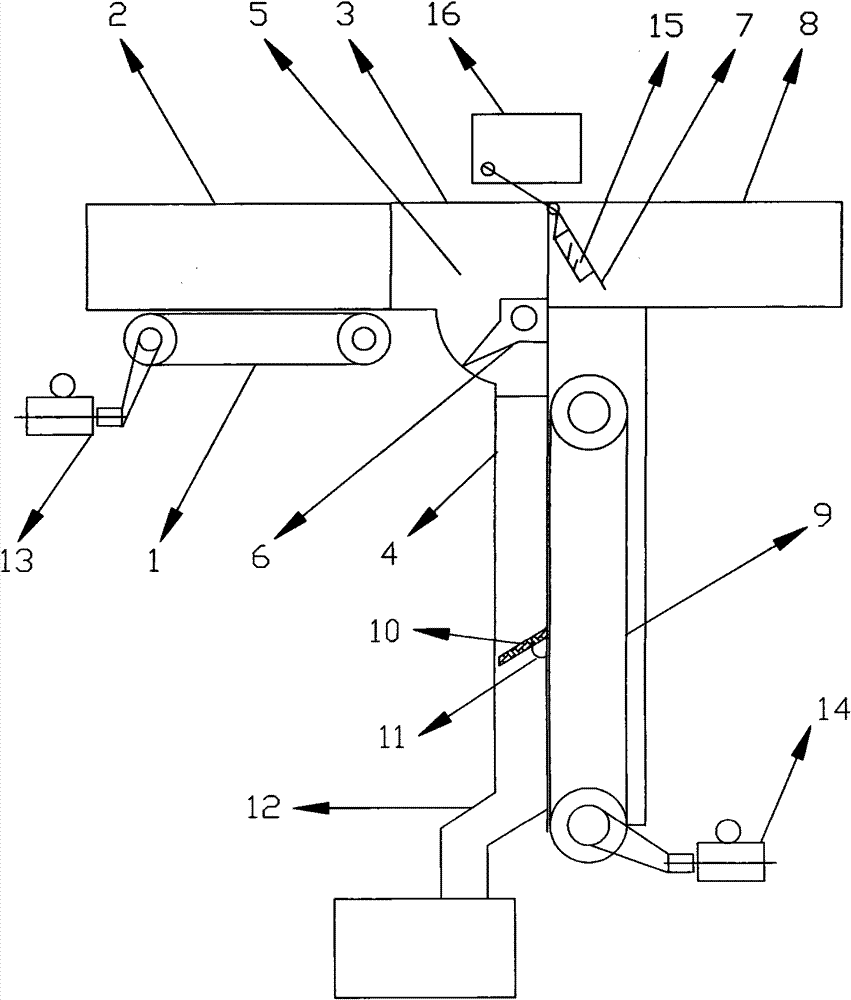

[0018] Referring to the accompanying drawings, the direction changing mechanism 3 is composed of a direction changing cavity 5, a material receiving adjustment block 6, and a flow regulating plate 7; The position is arc-shaped, at this time, the horizontal conveying channel is perpendicular to the direction-changing conveying channel; the material receiving adjustment block 6 changes the direction of the filter rod from the horizontal conveying channel to the changing direction conveying channel 4; the flow regulating plate 7 can move from the vertical position to the emergency The output channel 8 direction is open. The direction-changing conveying channel 4 has a rectangular cross-section, and three sides of the changing direction conveying channel 4 are fixed channel side plates, and one side is a crawler-type reversing conveying mechanism 9, and the reversing conveying mechanism 9 is fixedly connected with a platen 10, and the platen 10 is connected to the The reversing co...

Embodiment 2

[0022] As shown in the drawings, the direction changing mechanism 3 is composed of a direction changing cavity 5, a material receiving adjustment block 6, and a flow regulating plate 7; The matching position is arc-shaped; at this time, the horizontal conveying channel is perpendicular to the direction-changing conveying channel; the material receiving adjustment block 6 changes the direction of the cigarettes from the horizontal conveying channel 2 to the changing direction conveying channel 4; the flow regulating plate 7 can be vertically The position is opened toward the direction of emergency output channel 8. The direction-changing conveying channel 4 has a rectangular cross-section, and three sides of the direction-changing conveying channel 4 are fixed channel side plates, and one side is a chain-type changing direction conveying mechanism 9, and the changing direction conveying mechanism 9 is fixedly connected to the platen 10, and the platen 10 is connected to the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com