Chemical-mechanical polishing solution

A chemical mechanical and polishing liquid technology, which is applied in the fields of polishing compositions containing abrasives, electrical components, semiconductor/solid-state devices, etc., can solve the problems of high polysilicon/silicon dioxide selection ratio and difficult removal of polysilicon, and achieve reduction Effects of metal ion contamination and environmental pollution, productivity improvement, and high planarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

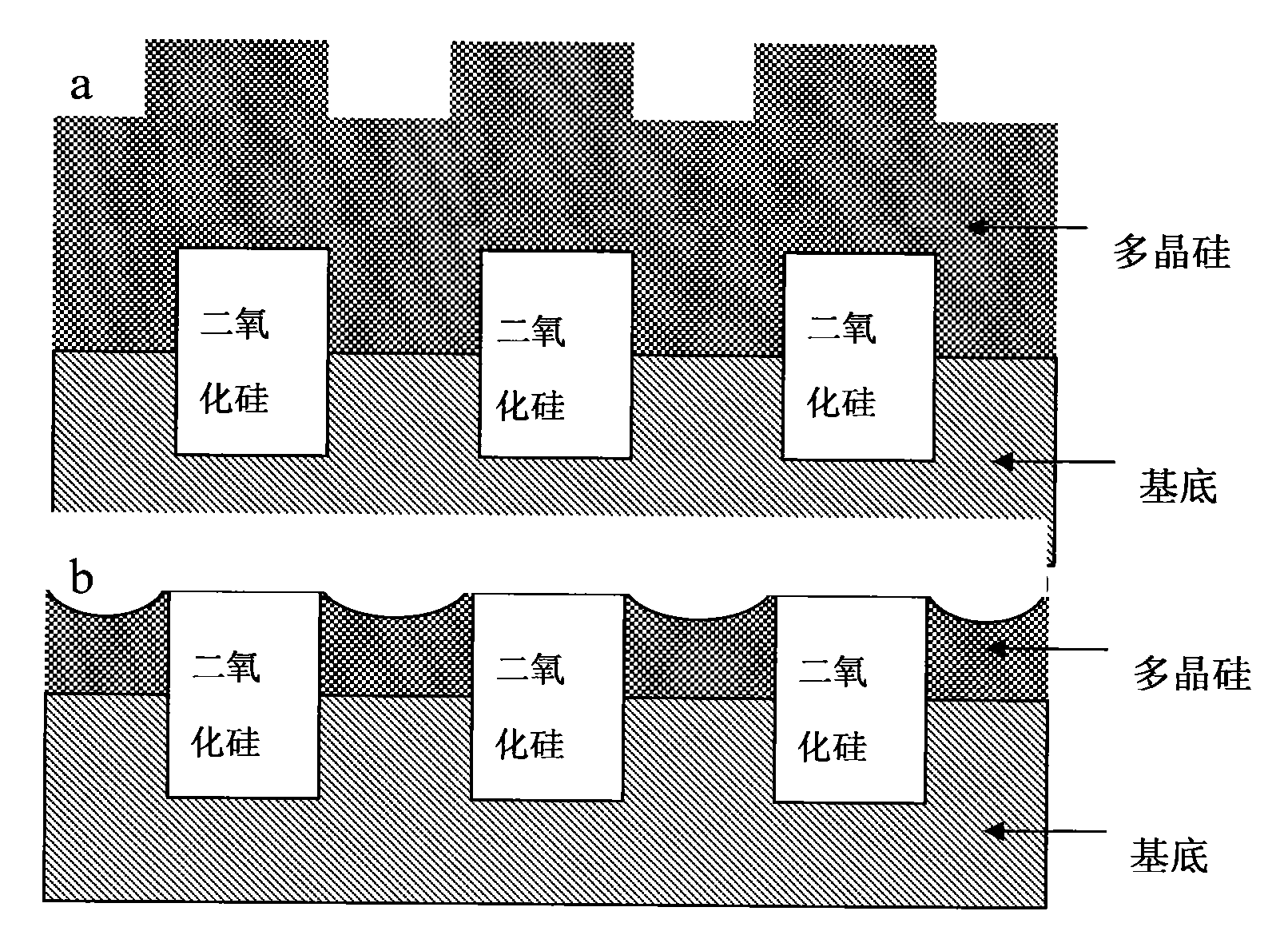

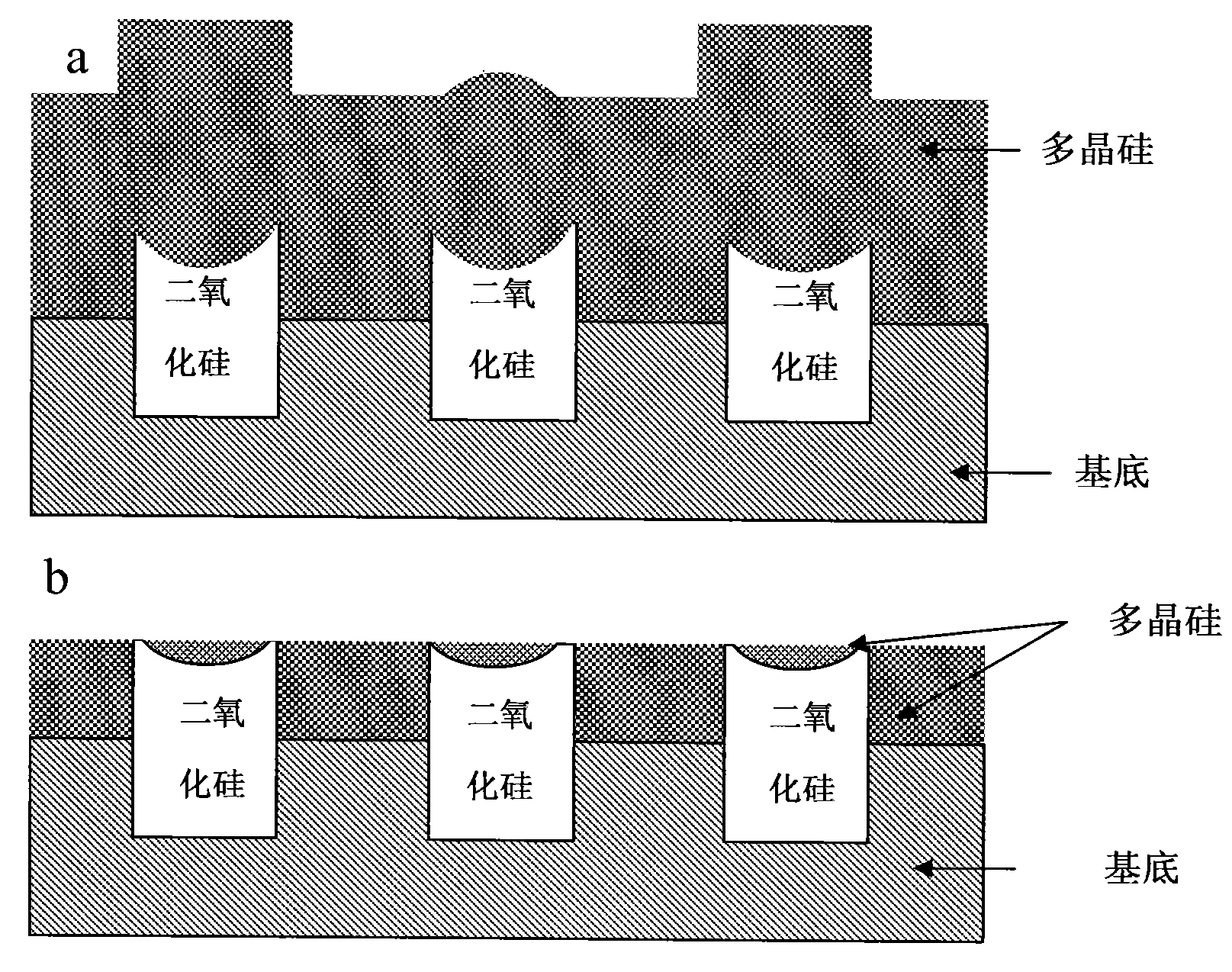

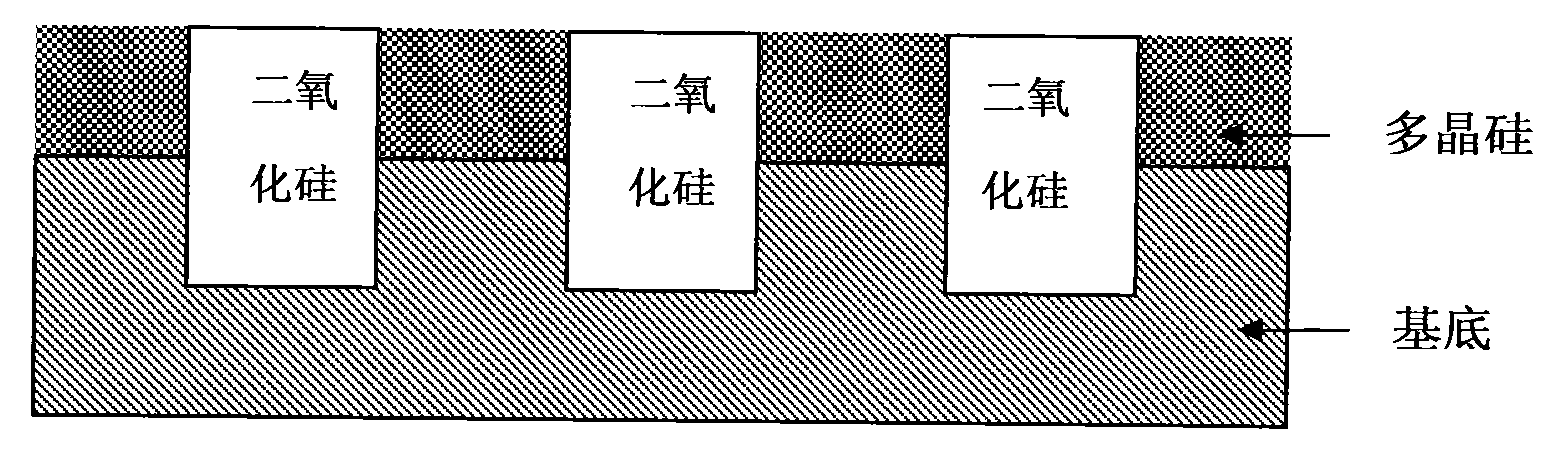

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The chemical mechanical polishing fluid of embodiment 1 polysilicon

[0032] Table 1 shows the formulas of polysilicon chemical mechanical polishing fluids 1 to 21 of the present invention, and the polishing fluids of each embodiment can be obtained by mixing the components and their contents given in the table evenly, with water as the balance.

[0033] Table 1 Chemical Mechanical Polishing Fluids 1-21 for Polysilicon

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com