Chemical and mechanical polishing solution

A chemical-mechanical and polishing liquid technology, used in polishing compositions containing abrasives, electrical components, semiconductor/solid-state device manufacturing, etc. Effects of metal ion contamination and environmental contamination, productivity improvement, and wide process window

Inactive Publication Date: 2011-06-29

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

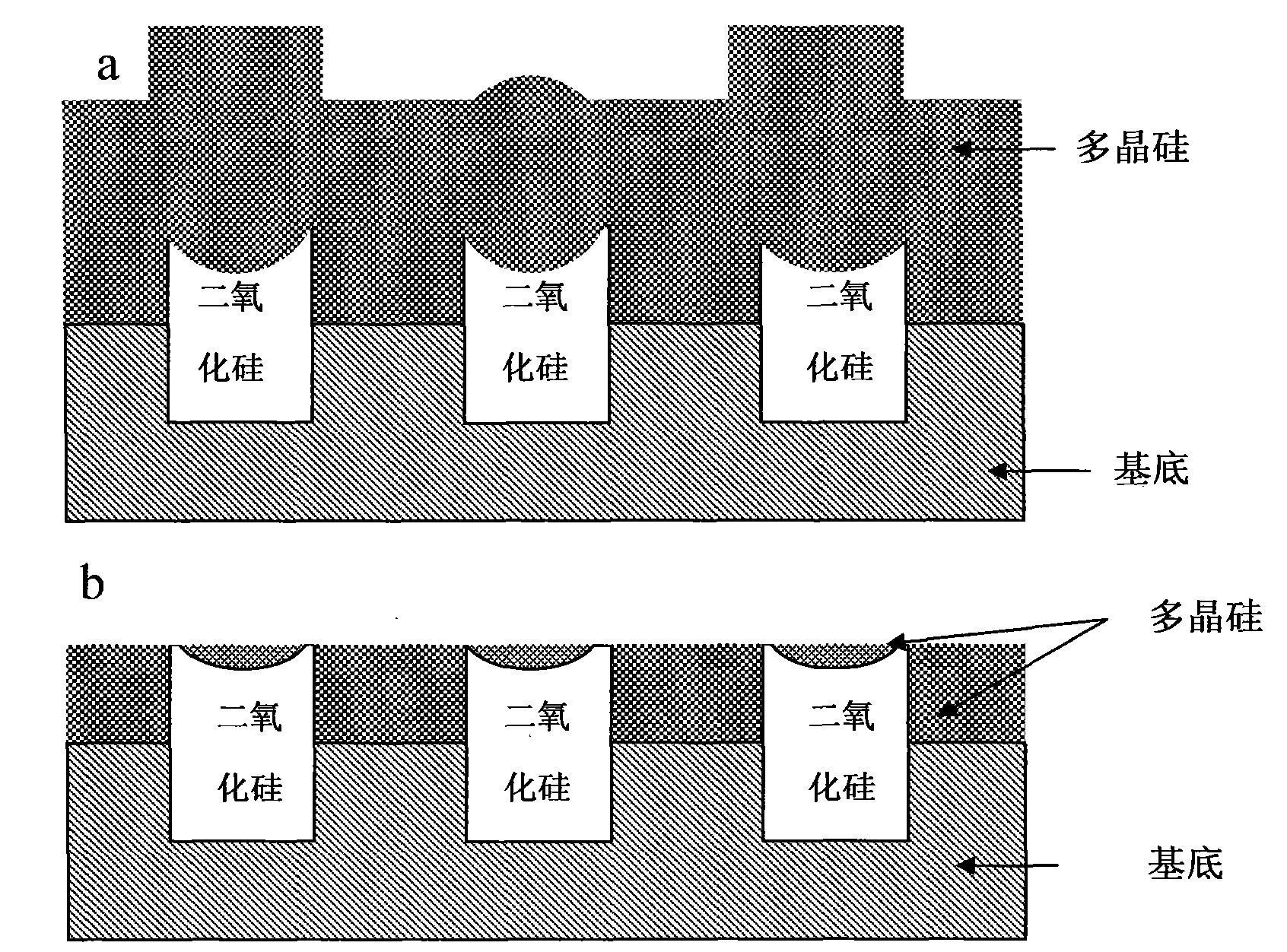

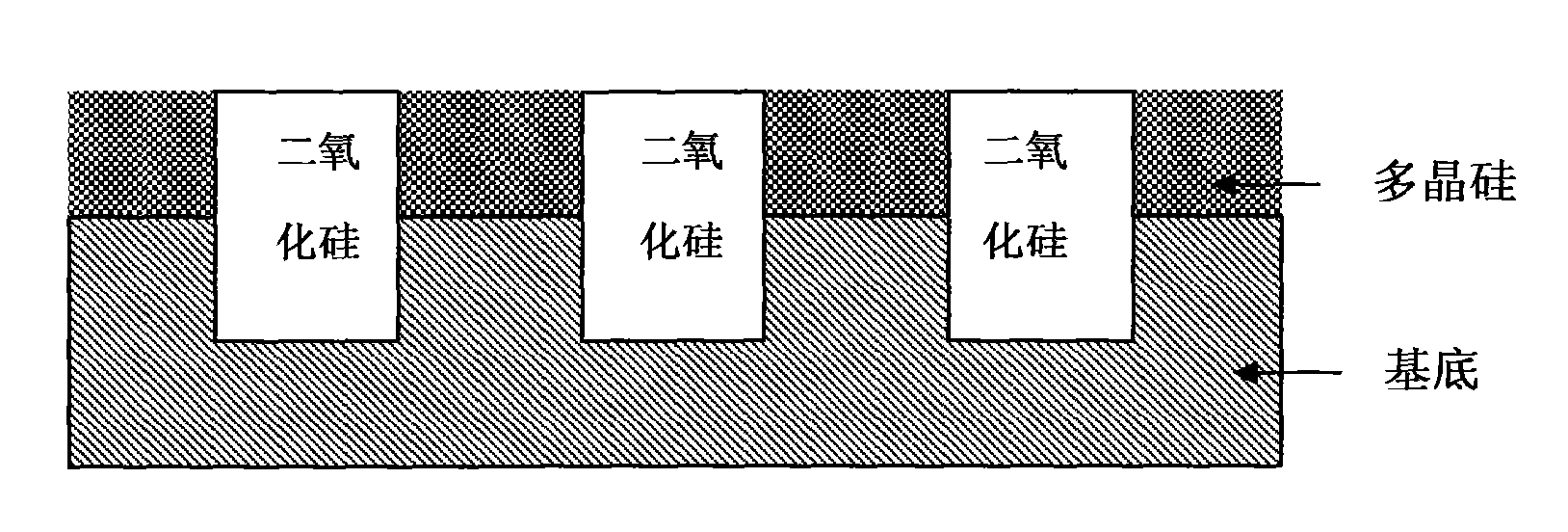

[0005] The purpose of the present invention is to solve the problem that the above-mentioned polysilicon / silicon dioxide selectivity ratio is too high, and the remaining polysilicon in the silicon dioxide butterfly-shaped depression is difficult to remove, and to provide a kind of polysilicon / silicon dioxide with suitable polysilicon for polishing polysilicon CMP

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] The chemical mechanical polishing fluid of embodiment 1 polysilicon

[0031] Table 1 shows the formulas of chemical mechanical polishing fluids 1-22 of the present invention, and the polishing fluids of each embodiment can be obtained by mixing the components given in the table and their contents evenly, with water as the balance.

[0032] Table 1 Chemical Mechanical Polishing Fluids 1-22 for Polysilicon

[0033]

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to polishing solution for chemical and mechanical polishing of silicon. The polishing solution contains water, grinding particles, at least one silicon accelerator and at least one silicon inhibitor. In the polishing solution, by regulating the amount of the silicon accelerator and the amount of the silicon inhibitor, the selection ratio of silicon to silicon dioxide can be regulated, and the planarization efficiency can be improved.

Description

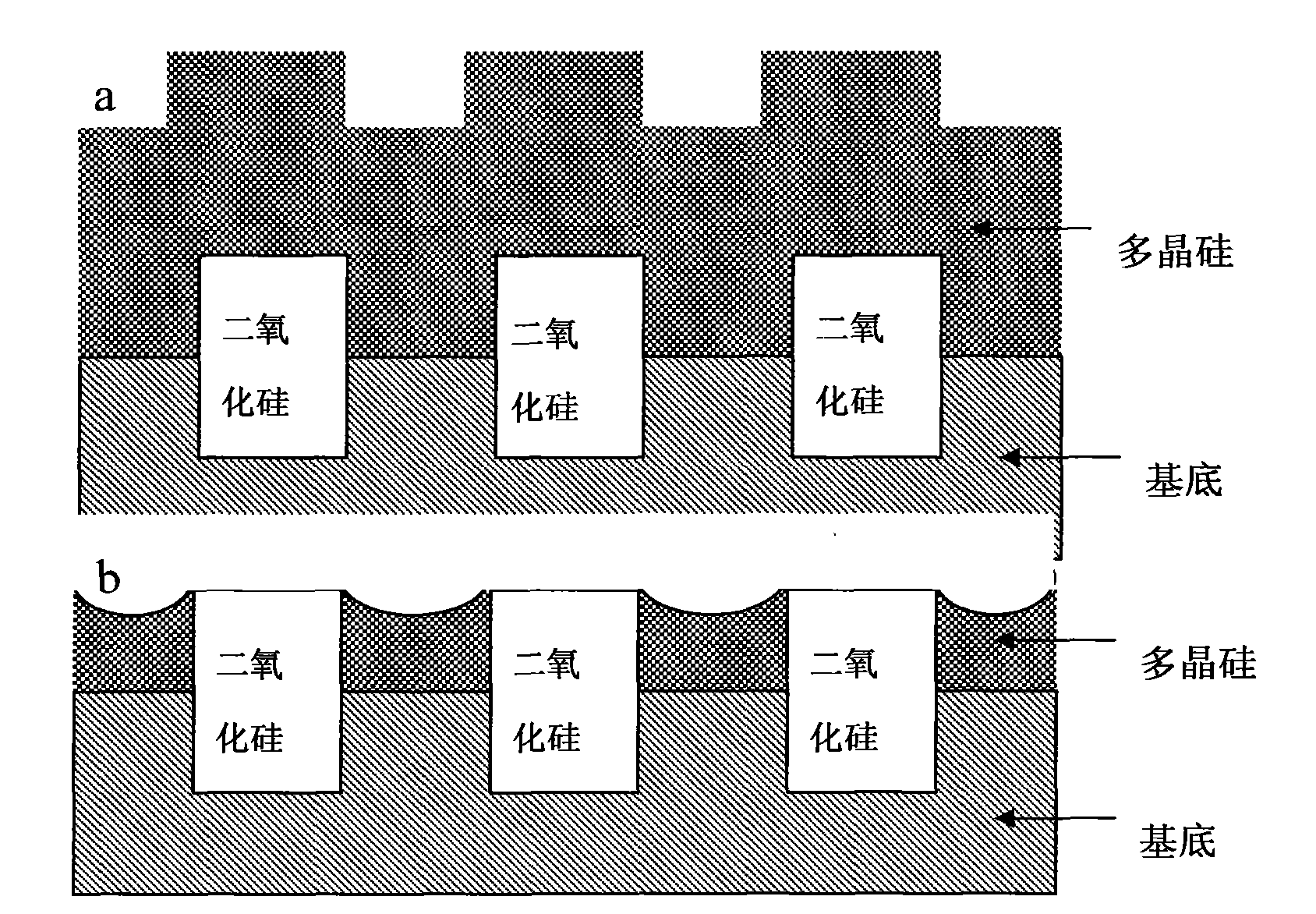

technical field [0001] The invention relates to a chemical mechanical polishing fluid, in particular to a chemical mechanical polishing fluid for polishing polysilicon. Background technique [0002] In the manufacture of integrated circuits, the standard of interconnect technology is increasing, and layers are deposited on top of each other, resulting in the formation of irregular topography on the substrate surface. A planarization method used in the prior art is chemical mechanical polishing (CMP). The CMP process uses a mixture containing abrasives and a polishing pad to polish the surface of a silicon wafer. In a typical chemical mechanical polishing method, the substrate is placed in direct contact with a rotating polishing pad, and a load is used to exert pressure on the backside of the substrate. During polishing, the pad and stage are rotated while maintaining a downward force on the backside of the substrate to apply an abrasive and chemically active solution (comm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09G1/02H01L21/306H01L21/762

Inventor 荆建芬蔡鑫元

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com