A cleaning solution and cleaning method for cleaning the backside of a silicon wafer before metallization

A technology of backside metallization and silicon wafers, which is applied in the direction of chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of excessive metal corrosion and the inability to remove the residue of the front peeling film, so as to improve the quality of products rate, reduce the selectivity ratio, and reduce the effect of positive metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose and technical solution of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0029] The invention provides a cleaning solution for cleaning before metallization on the back side of a silicon wafer, wherein the cleaning solution is etching solution BOE and ethylene glycol (molecular formula is: C 2 h 6 o 2 ), the volume ratio of the ethylene glycol to the etching solution BOE is any ratio between 14 / 1 and 18 / 1.

[0030] The etchant BOE is made of 40% NH 4 The F (ammonium fluoride) solution and the 49.2% HF (hydrogen fluoride) solution were mixed in a volume ratio of 7 / 1.

[0031] In order to make the cleaning effect of the solution more obvious, the concentration of the ethylene glycol EG is above 98%.

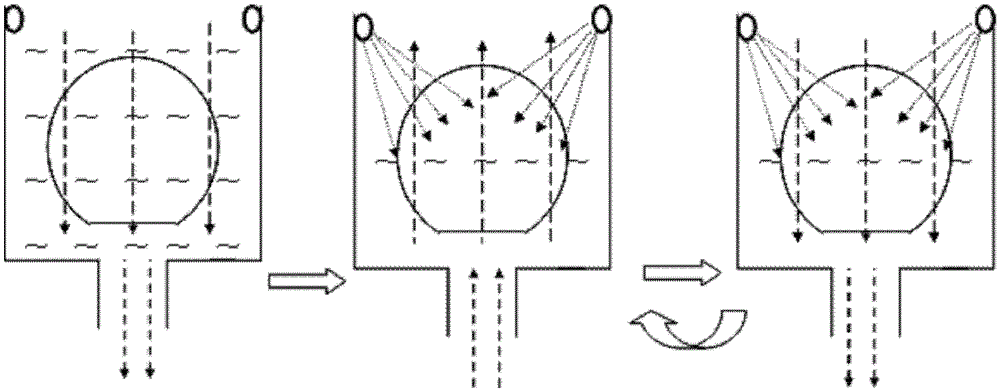

[0032] When using the prepared cleaning solution to clean the silicon wafer, first pour the mixed cleaning solution in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com