Shock absorber

A technology of buffers and pilot chambers, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of excessive rise, decrease, and inability to obtain attenuation characteristics, and achieve stable attenuation force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

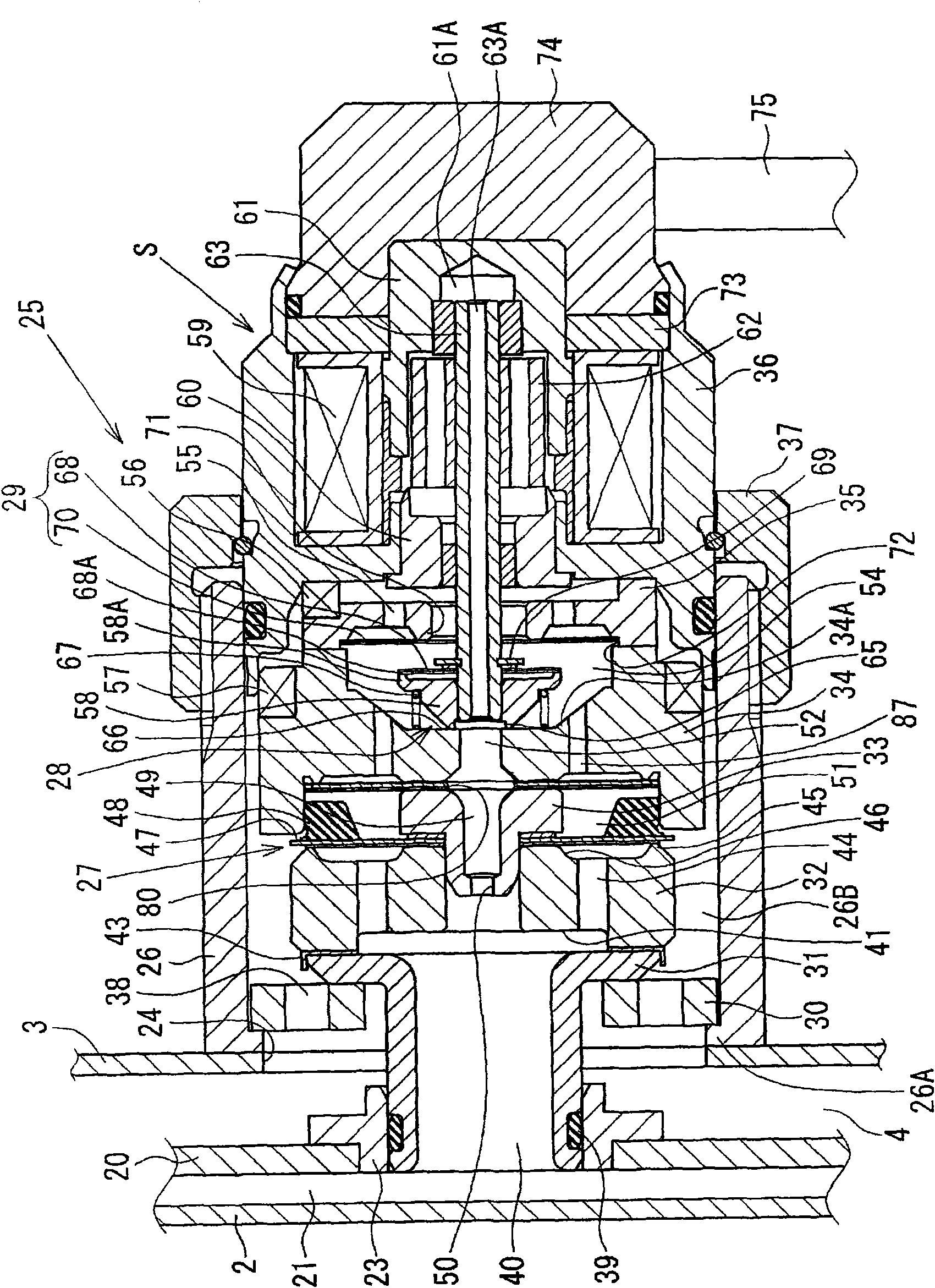

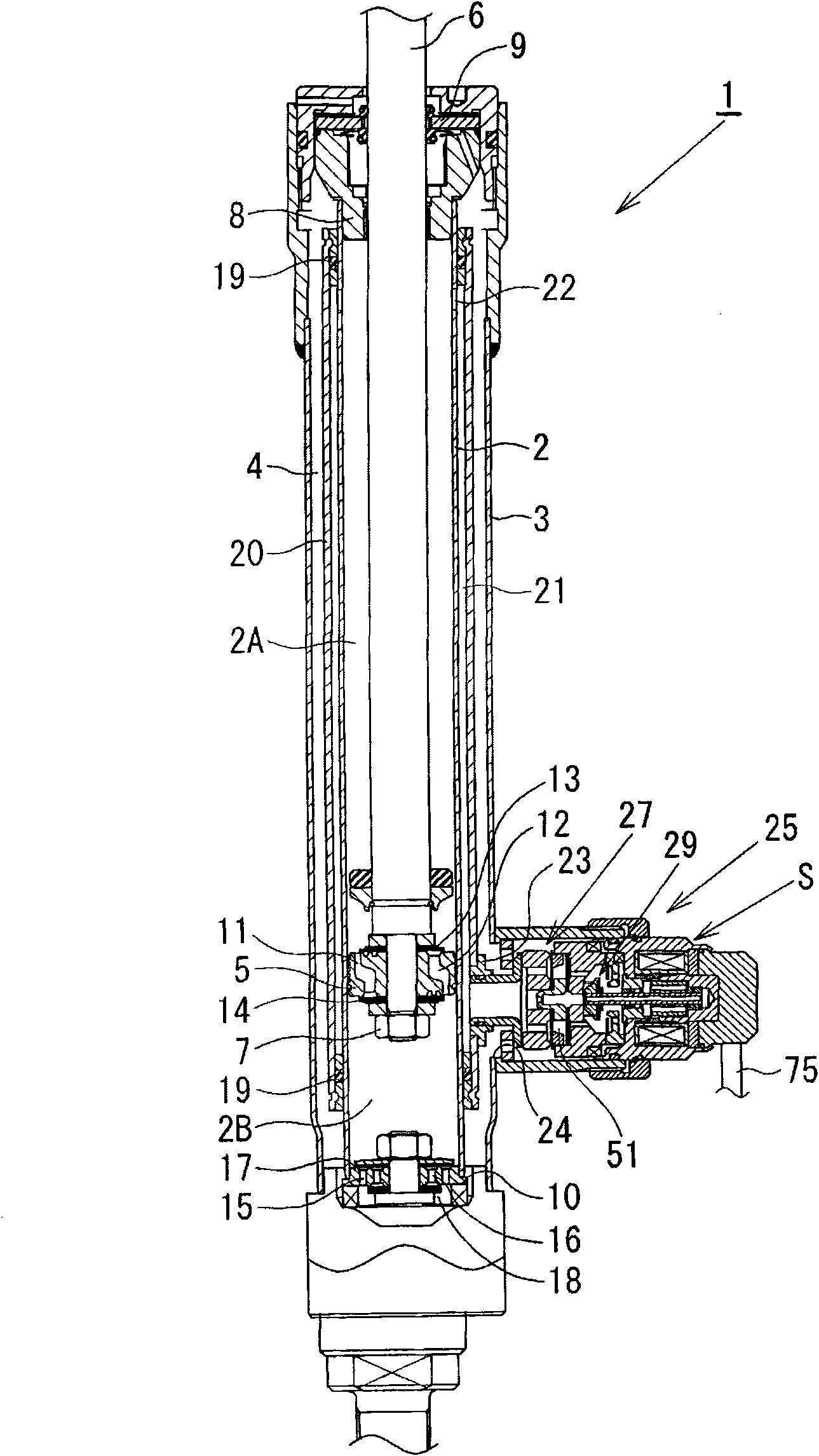

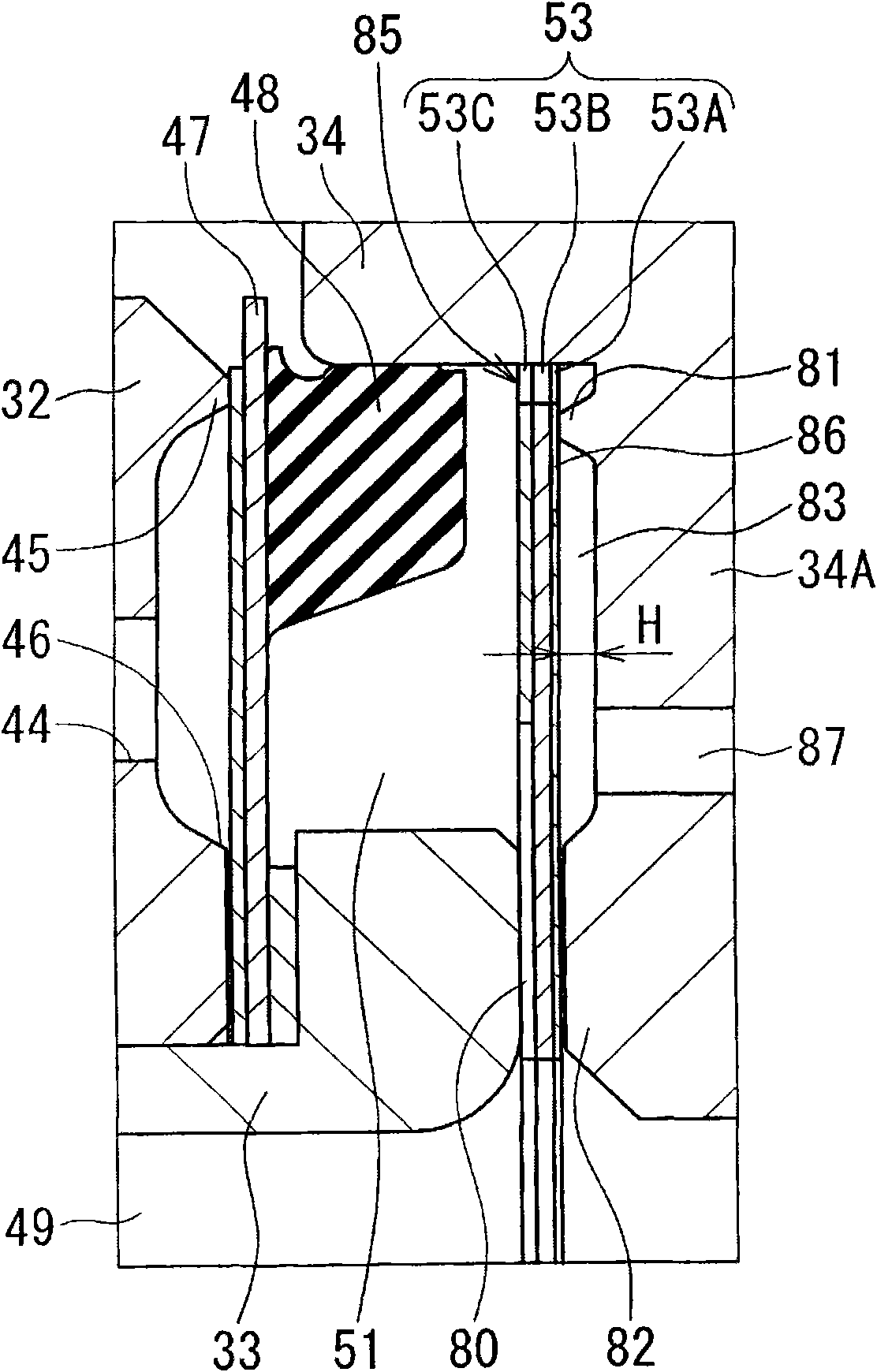

[0022] Hereinafter, one embodiment of the present invention will be described in detail with reference to the drawings. like figure 2 As shown, the damping force adjustable hydraulic shock absorber 1 as the shock absorber according to the present embodiment has a multi-tube structure in which the outer cylinder 3 is provided outside the cylinder 2 , and a gap is formed between the cylinder 2 and the outer cylinder 3 . storage room4. A piston 5 is slidably embedded in the cylinder 2, and the piston 5 divides the interior of the cylinder 2 into two chambers: a cylinder upper chamber 2A and a cylinder lower chamber 2B. One end of the piston rod 6 is connected to the piston 5 through a nut 7, and the other end of the piston rod 6 passes through the upper chamber 2A of the cylinder body, and penetrates through the rod guide 8 and the oil seal 9 installed on the upper ends of the cylinder body 2 and the outer cylinder 3 And extend to the outside of cylinder body 2. On the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com