An electromagnetic damper

An electromagnetic damper and damping force technology, applied in the directions of magnetic springs, springs/shock absorbers, springs, etc., can solve the problems of large changes in the damping force environment, low friction life of copper sheets, and large volume, etc., to achieve stable damping force, Improve product life and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Provide the preferred scheme of implementing the present invention below, and illustrate in conjunction with accompanying drawing.

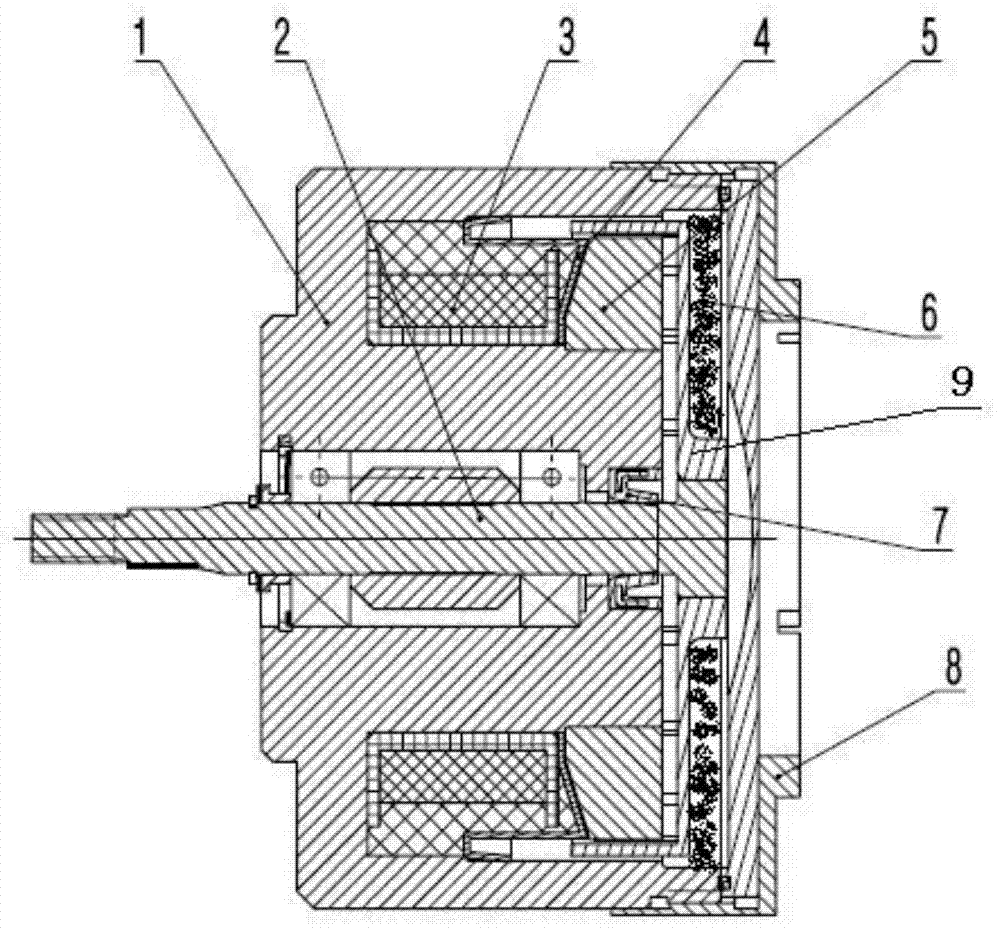

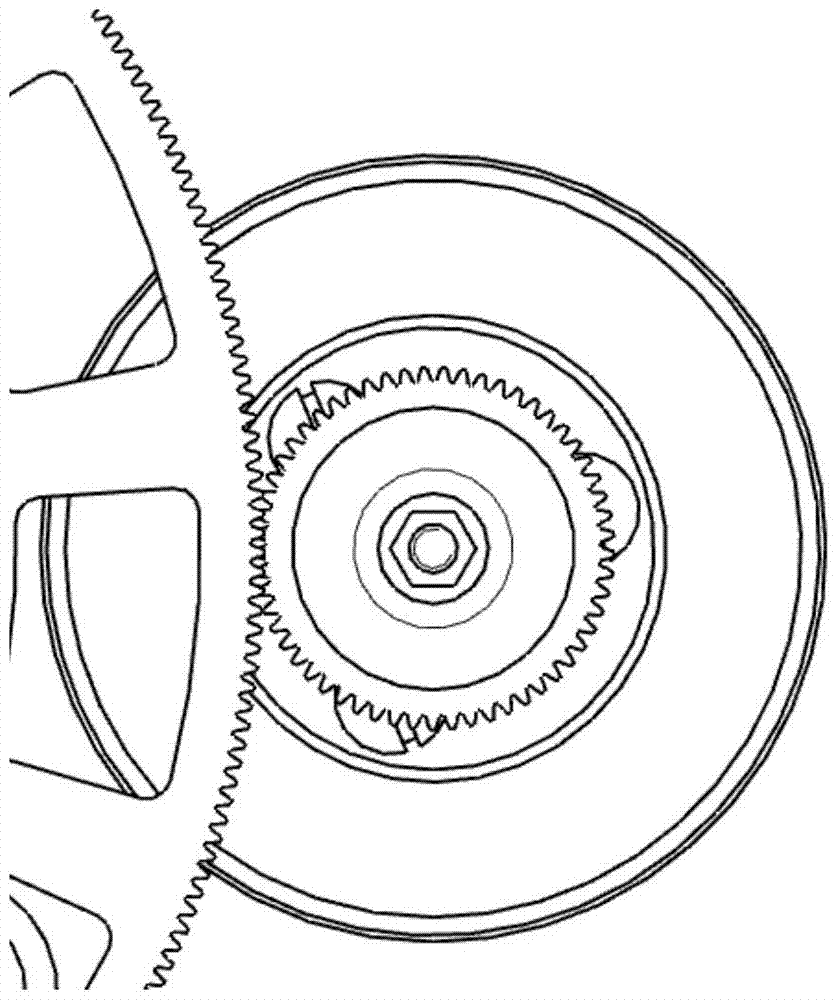

[0018] An electromagnetic damper, used to provide operation damping force in the fly-by-wire mode, which includes a housing 1, a rotor 2, a coil assembly 3, a magnetic isolation ring 4, a pole shoe 5, a rear cover 8 and an umbrella body 9, wherein

[0019] The housing 1 is fixedly installed inside the accelerator platform, has an annular groove on one end surface, and has a hole for installing the rotor 2 in the middle; one end of the rotor 2 is connected to the control handle of the fly-by-wire throttle of the aircraft through a gear and linkage mechanism , the other end is fixedly connected to the umbrella body 9, and the rod is supported in the hole through a bearing; the umbrella body 9 has an annular wall extending and inserted into the annular groove, and there is a gap between the annular wall and the housing 1; The back cover 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com