Direct liquid level boundary indicator

A measuring instrument and liquid level technology, which is applied in the field of measuring instruments, can solve the problems of detection components such as pressure deformation, large measurement error, and measurement error, and achieve the effects of controlling oil-water separation, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

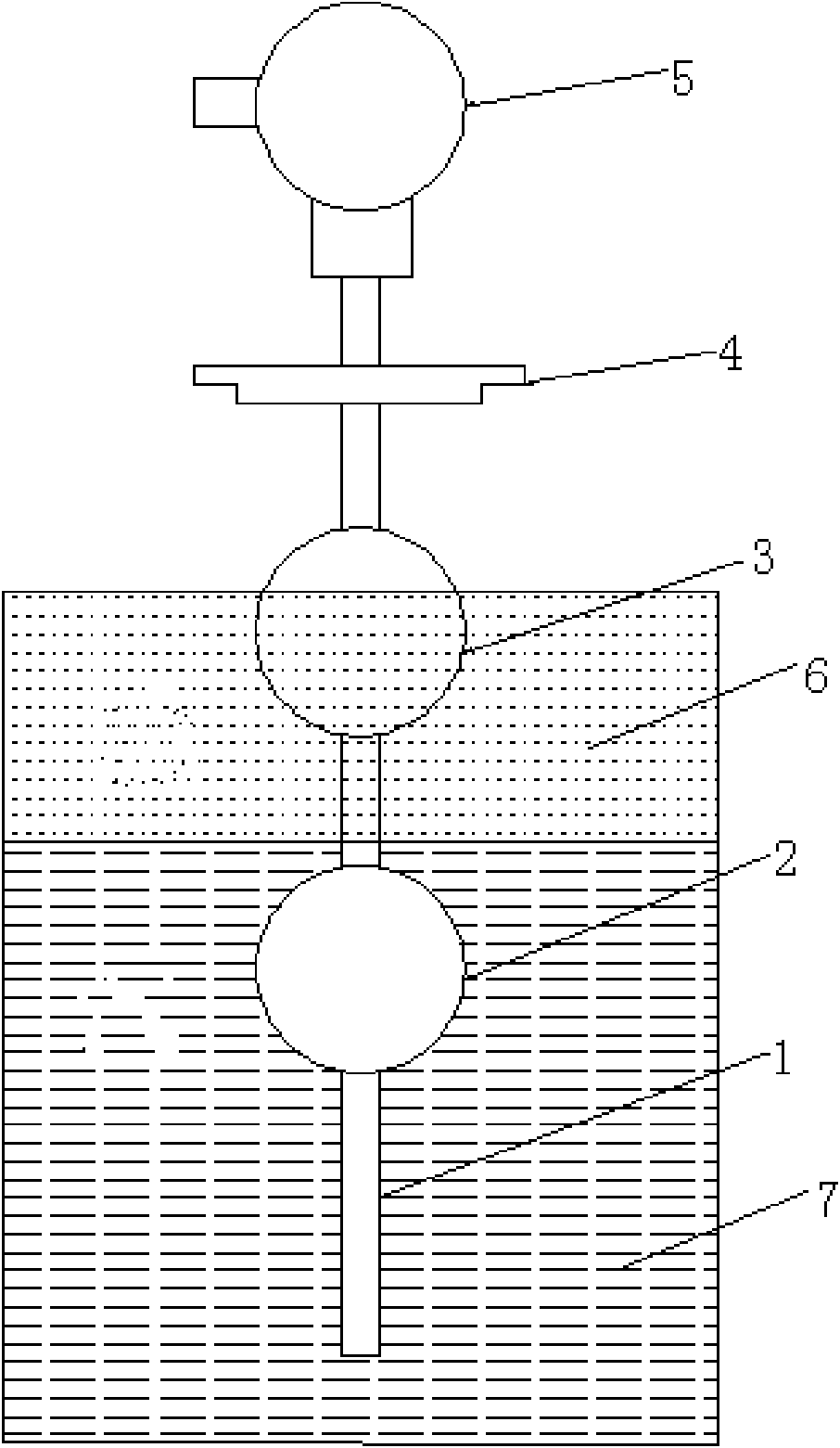

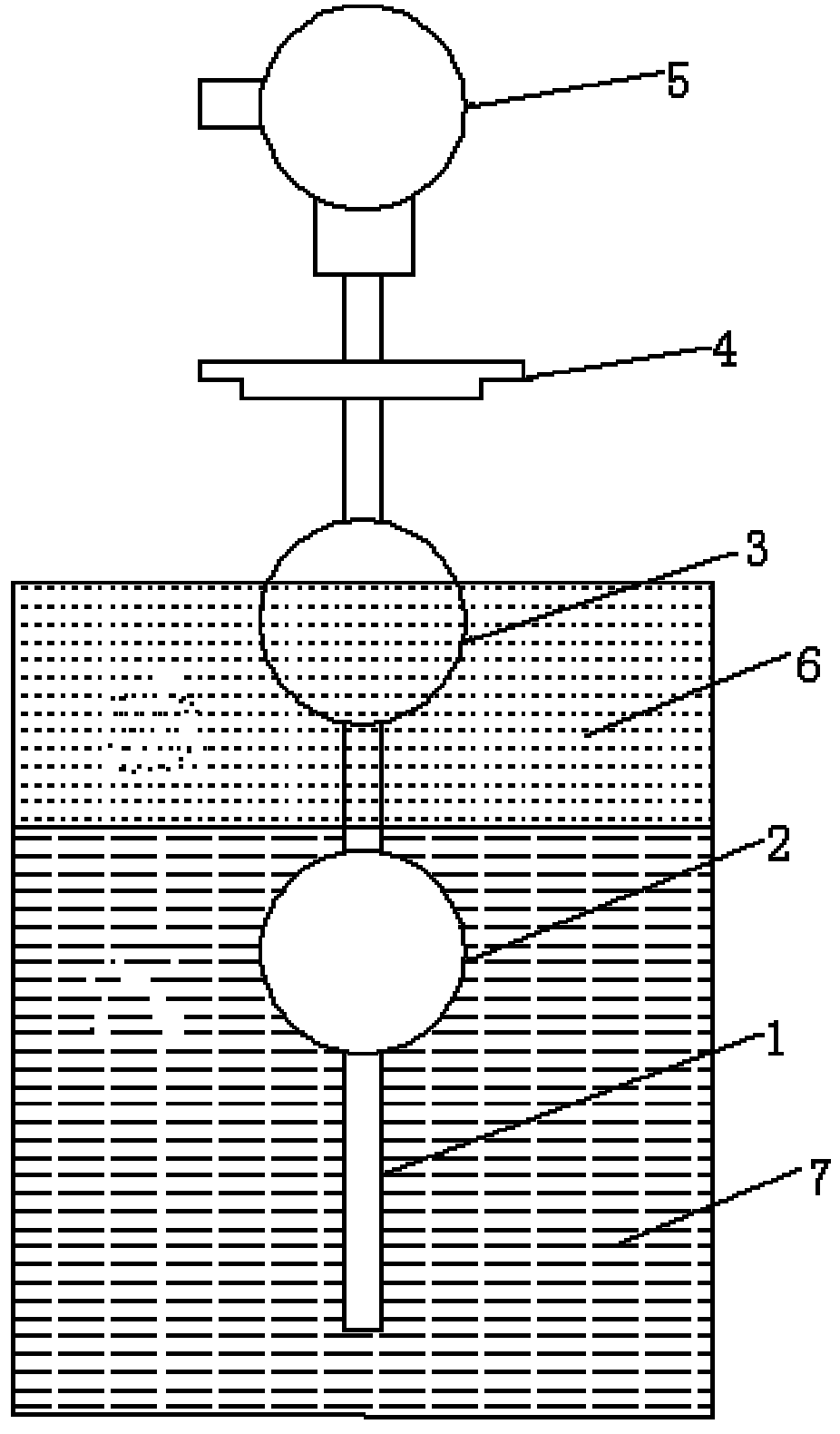

[0011] refer to figure 1 , The sensor shell (1) is sequentially connected to the interface float (2), the liquid surface float (3), the mounting flange (4), and the transmitter shell (5) to form an integral body. When in use, the sensor housing (1) is connected with a sensor, and the present invention is placed in the mixed liquid of oil (6) and water (7), so that it can be used to measure the interface of oil (6) and water (7).

[0012] 1. Adjust the weight of the interface floating ball (2) so that it can sink into the water (7) liquid, and can float well between the water (7) liquid, so that it can truly reflect the height of the interface. The sensor directly measures the position of the floating ball on the interface, and through the transmission unit, the position signal is converted into a 4-20mADC signal and transmitted to the monitoring and control system.

[0013] 2. Adjust the weight of the liquid surface float (3) so that its upper part can float out of the oil (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com