Wear prediction method for fine blanking dies based on finite-element technique and artificial neural network

A technology of artificial neural network and prediction method, which is applied in the field of fine blanking die wear prediction based on finite element technology and artificial neural network, and can solve problems such as inaccuracy and mold repair guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

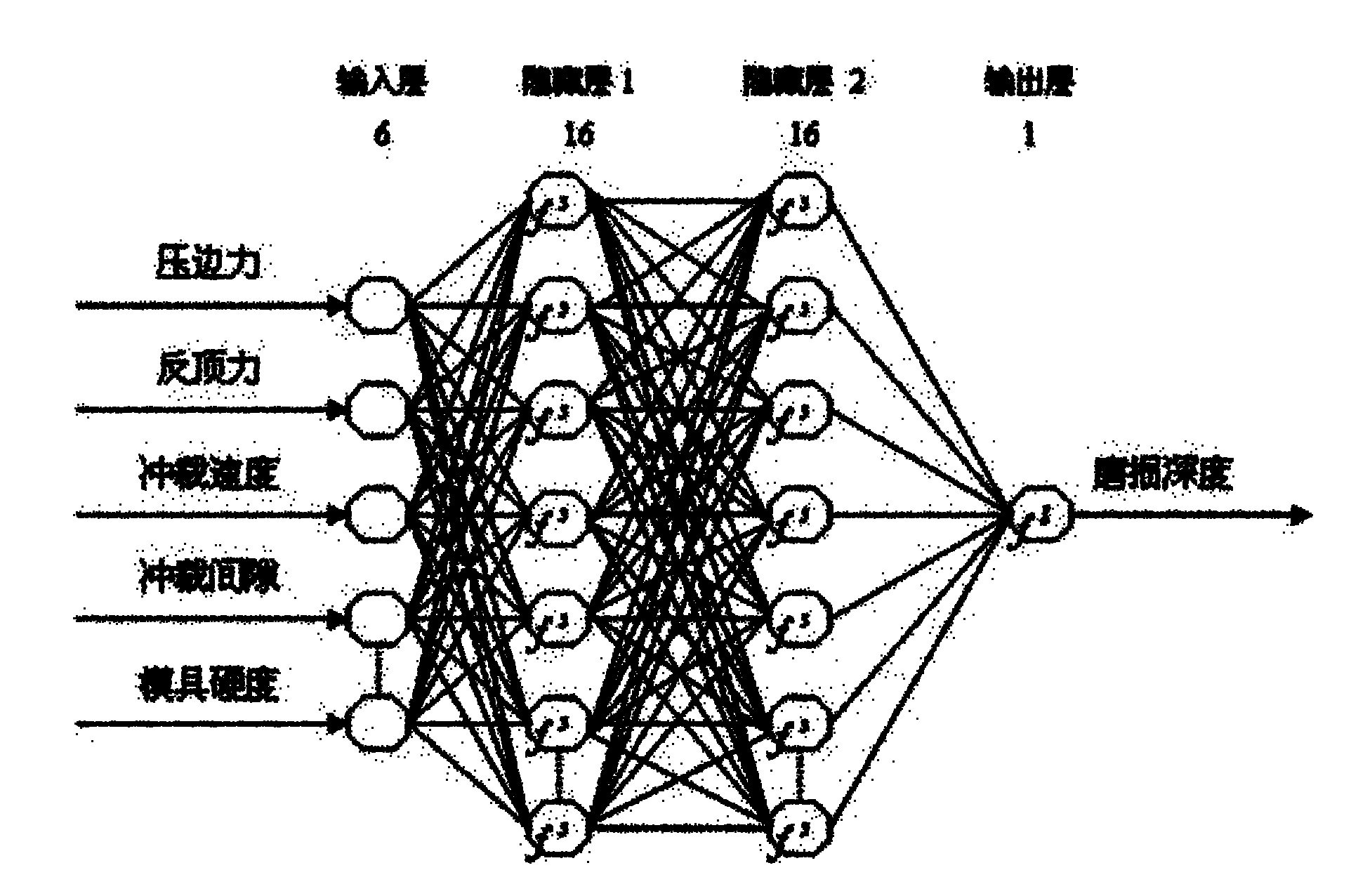

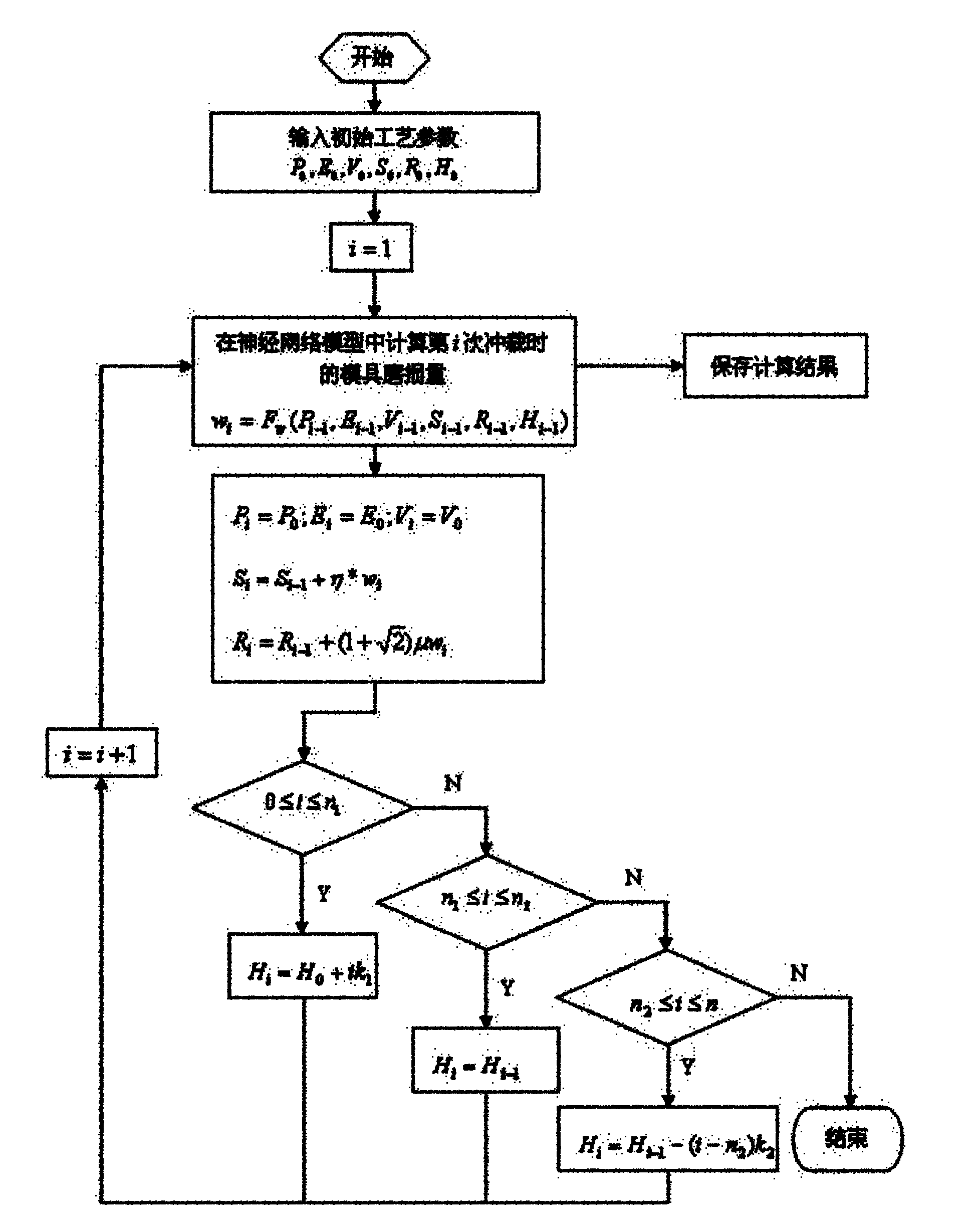

[0058] The method for predicting the wear of fine punching die based on the finite element technology and artificial neural network provided by the present invention takes the finite element analysis technology and the artificial neural network model as research methods, and establishes the wear prediction model of the fine punching die on the Matlab computing platform, which can quickly and accurately Predict the instant wear of the die and the total die wear of any number of blankings to guide production.

[0059] The precision die wear prediction method based on finite element technology and artificial neural network includes the following implementation steps:

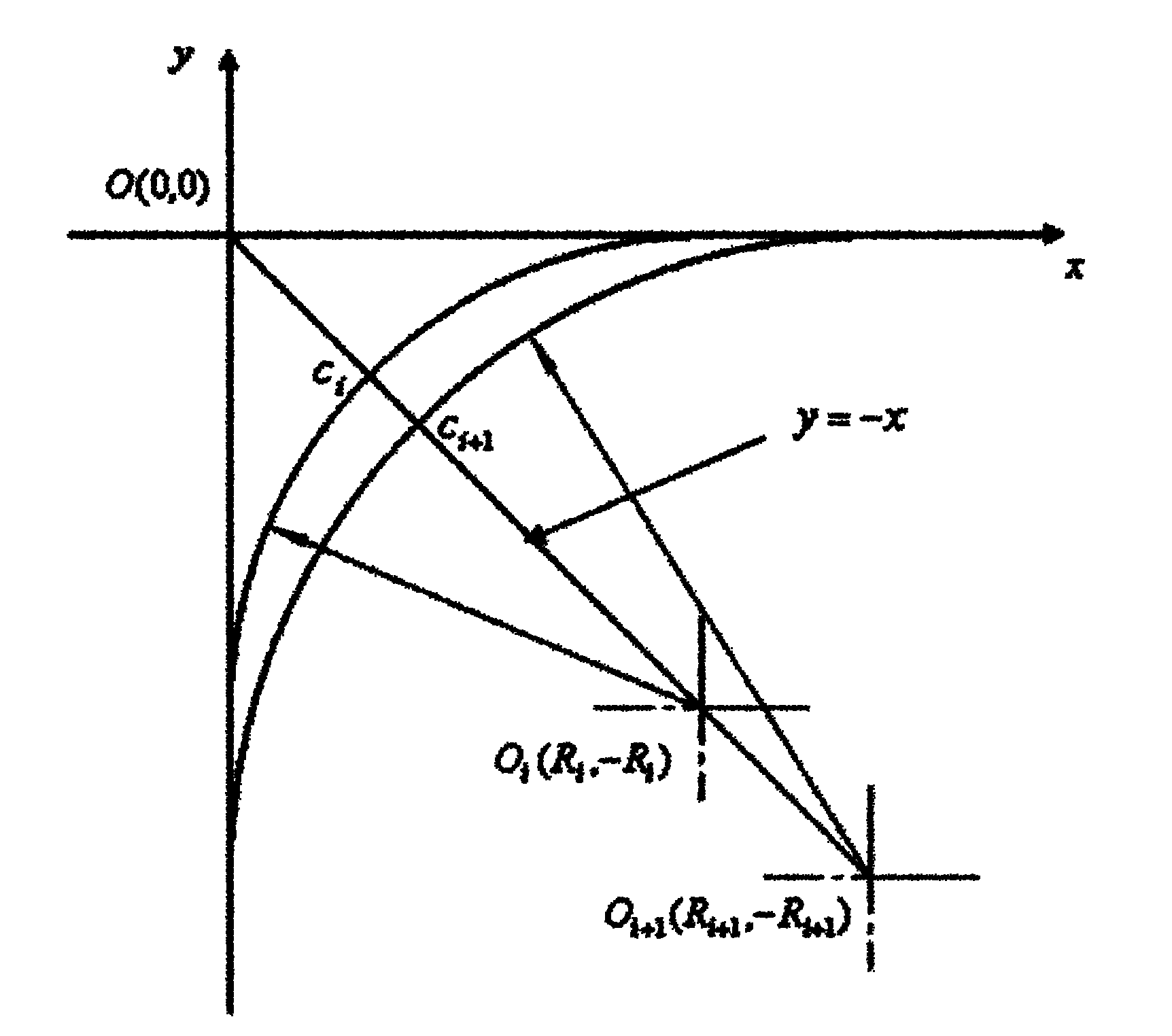

[0060] (1) Finite element analysis model: A finite element analysis model of fine die wear is established in Deform-3D. The key steps for establishing the finite element analysis model are as follows:

[0061] 1) Fracture criterion

[0062] During the finite element analysis, the Normalized Cockcroft and Latham f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com