Vacuum arc extinguish chamber capacitive treating method and device

A vacuum interrupter and burn-in technology, which is applied to high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of expensive and large systems, and achieve the effects of low cost, reduced re-ignition rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

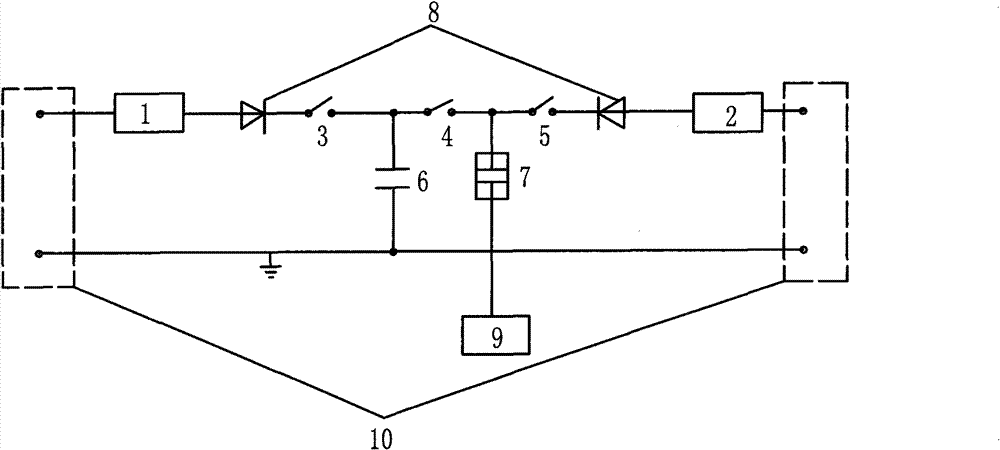

[0015] A capacitive aging method for a vacuum interrupter, which is characterized in that the aging of the vacuum interrupter in the low-current arcing state is carried out through the transient current generated after the capacitor is discharged, and the vacuum extinguisher in the closed state is aged. The arc chamber simulates actual inrush currents. The small current arcing state of the vacuum interrupter is that the auxiliary power supply of 50V~80V is rectified by the rectifier diode, and then the vacuum interrupter in the closed state is turned on, and then the contact of the vacuum interrupter is opened by 1mm~ through the operating mechanism. 10mm distance to achieve. The capacitor is charged after being rectified by the main power supply of 150V to 250V through a rectifier diode.

[0016] A kind of vacuum interrupter capacitive aging device that realizes the above method, such as figure 1 As shown, it is characterized in that it includes a capacitor 6 connected in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com