Protection device having functions of automatic control, energy moving and degradation self-separation for vacuum arc extinguish chamber

A vacuum interrupter and protection device technology, which is applied to high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve problems such as flashover along the surface, high residual voltage, and unstable protection, so as to reduce re-ignition overvoltage, The effect of increasing the flow capacity and protecting electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

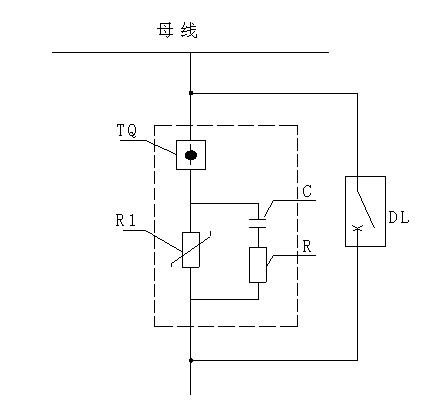

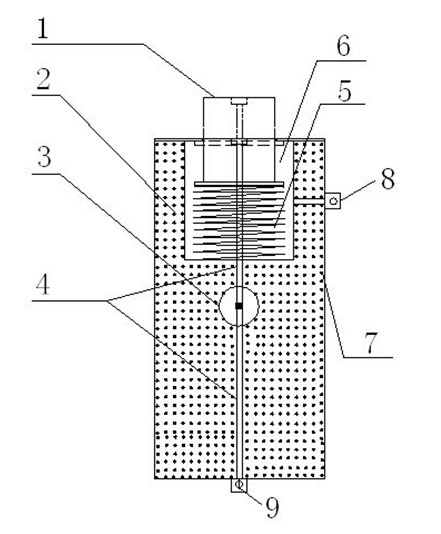

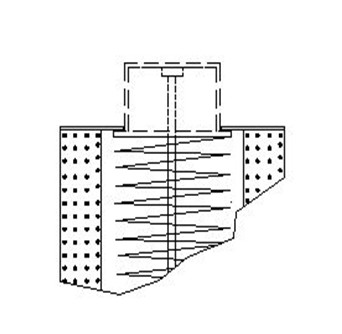

[0021] see Figure 1-3 , the present invention includes a degraded automatic disconnector TQ and an energy transfer element R1, both of which are connected in series; both ends of the energy transfer element R1 are connected in parallel with an R-C loop, and the resistor R and the capacitor C in the R-C loop are connected in series.

[0022] One end of the degraded automatic disconnector TQ is connected to the upper contact of the vacuum circuit breaker DL, the other end is connected in series with the energy transfer element R1, and the other end of the energy transfer element R1 is connected to the lower contact of the circuit breaker DL. The energy transfer element R1 is a nonlinear resistor with a 2mS square wave flow capacity of 400~800A. In this example, the value is 800A, which has a large flow capacity and a good nonlinear coefficient. In the R-C circuit, the resistor R is a linear resistor, which is 90~110Ω. In this example, the value is 100Ω. The function is to incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com