Packer fixing ring and oil/water self-expandable packer with same

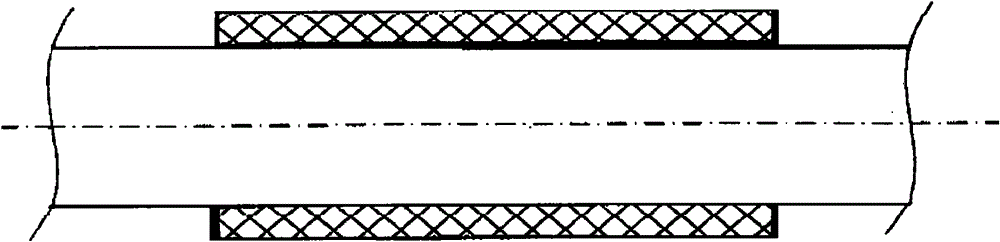

A packer and fixing ring technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc. The effect of a large expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are for reference and illustration only, and are not intended to limit the present invention.

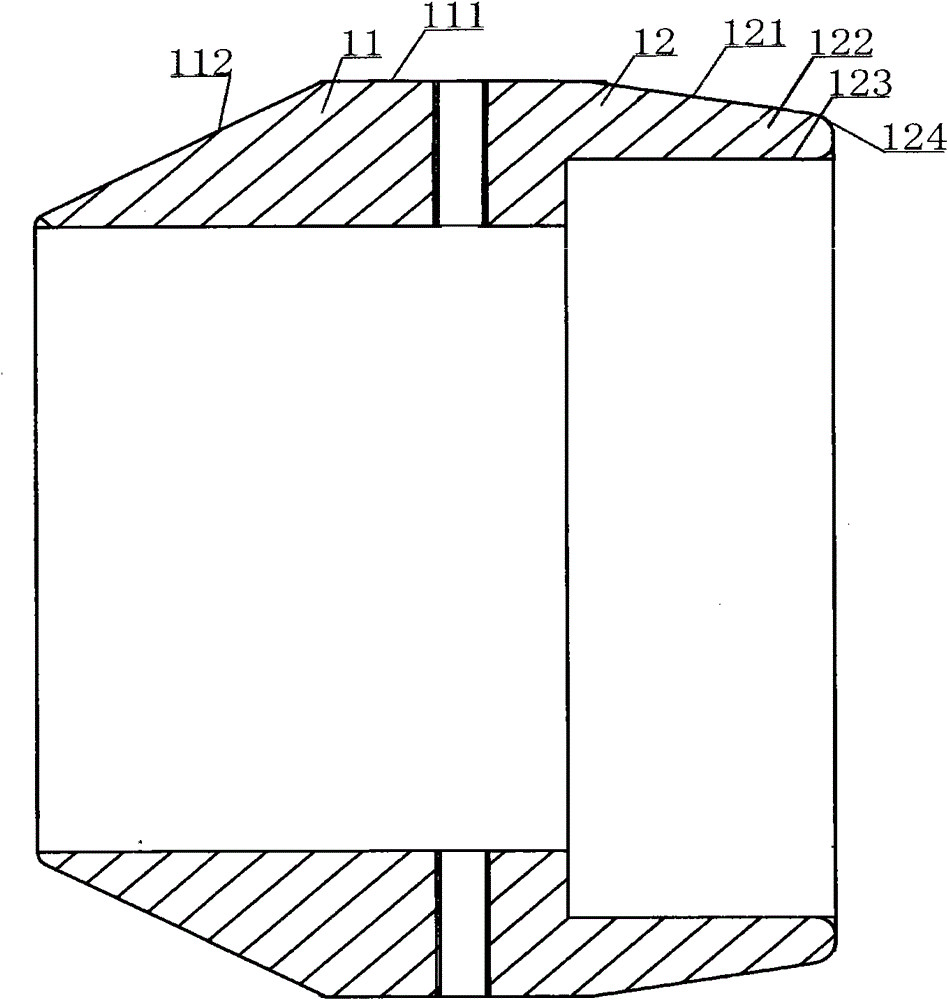

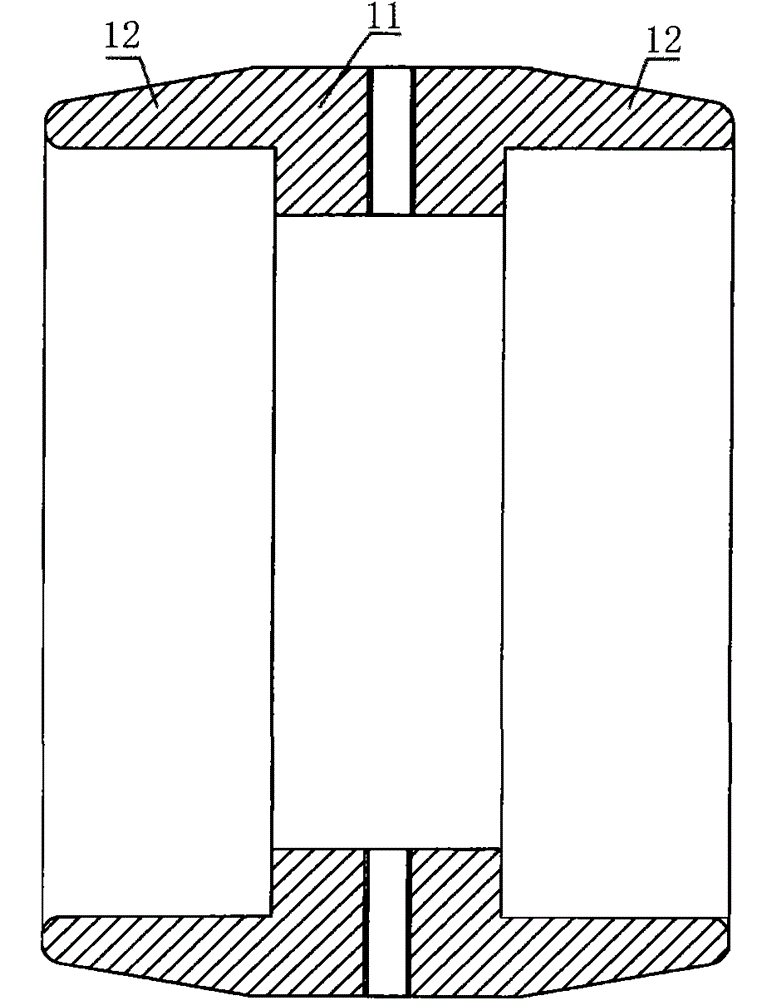

[0045] see figure 2 , is a structural schematic diagram of the first example of the packer fixing ring 1 of the present invention. The packer fixing ring is used to fix the self-expanding packer when encountering oil and water, which is sleeved on the base pipe, and the packer is used to self-expand and seal the space to be sealed when encountering oil and water; wherein the seal The spacer fixing ring 1 includes: a main body 11, which is used to be sleeved on the base pipe; one end of the main body 11 is provided with a fixing part 12; the fixing part 12 is used to be sleeved on the end of the packer to secure the end.

[0046] see again figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com