Control system and method for implementing double horizontal pressures in air passage, breathing machine and anaesthetic machine

A horizontal pressure and control system technology, applied in the direction of respirators, iron lungs, etc., can solve the problems of high cost, complex structure, unfavorable promotion, etc., and achieve the effect of simple design and low cost

Active Publication Date: 2011-07-06

BEIJING AEONMED

View PDF3 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the control process is complicated, the structure is compli

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

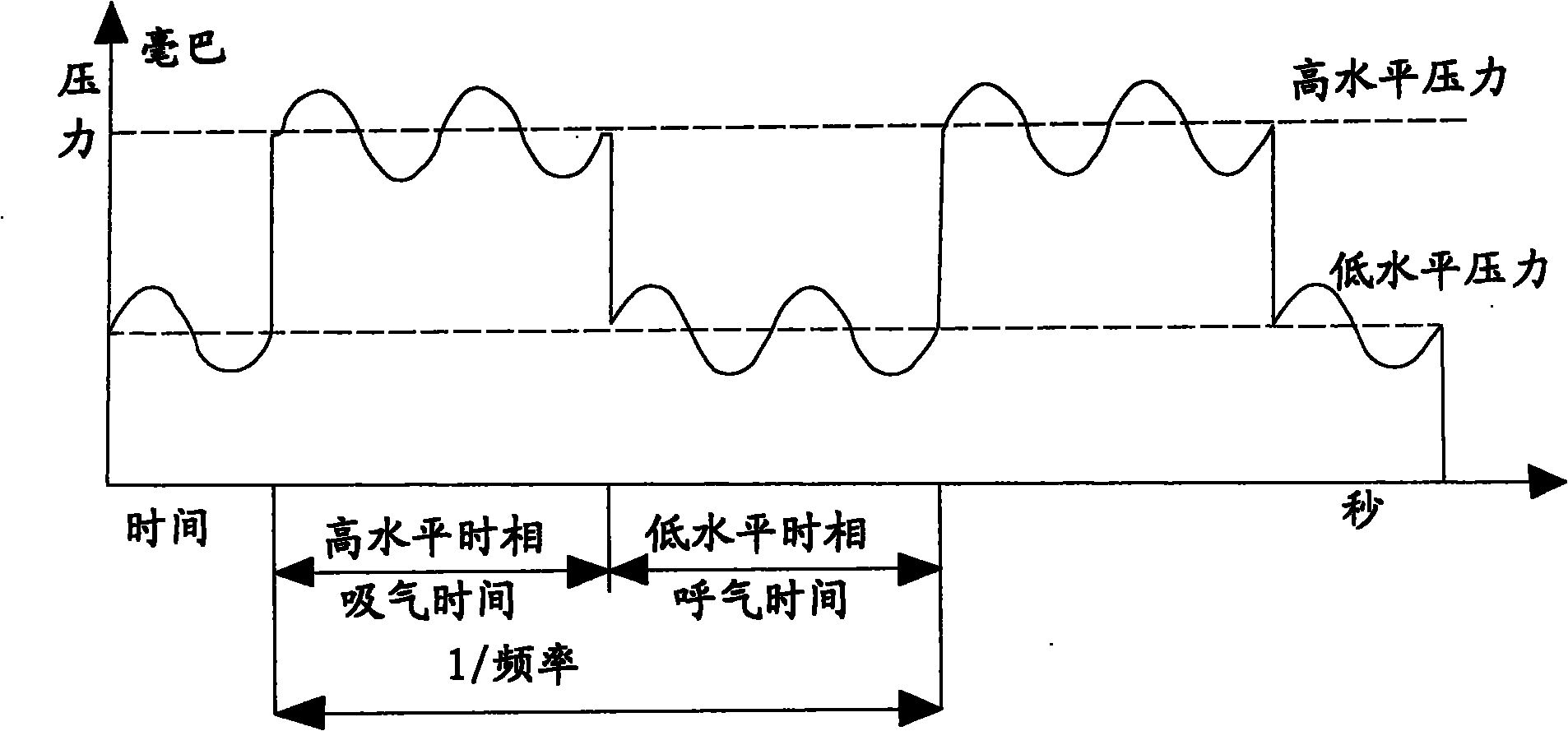

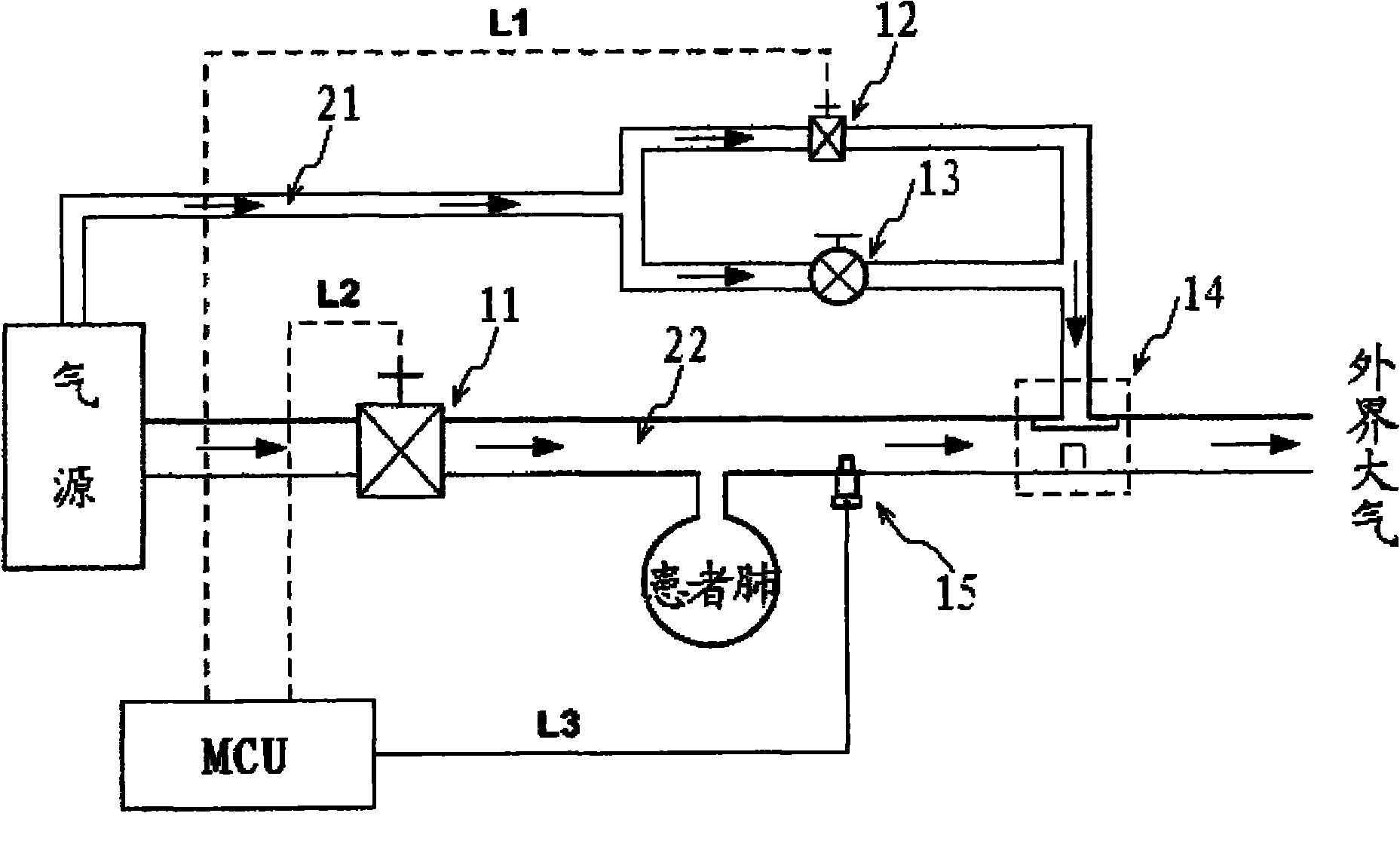

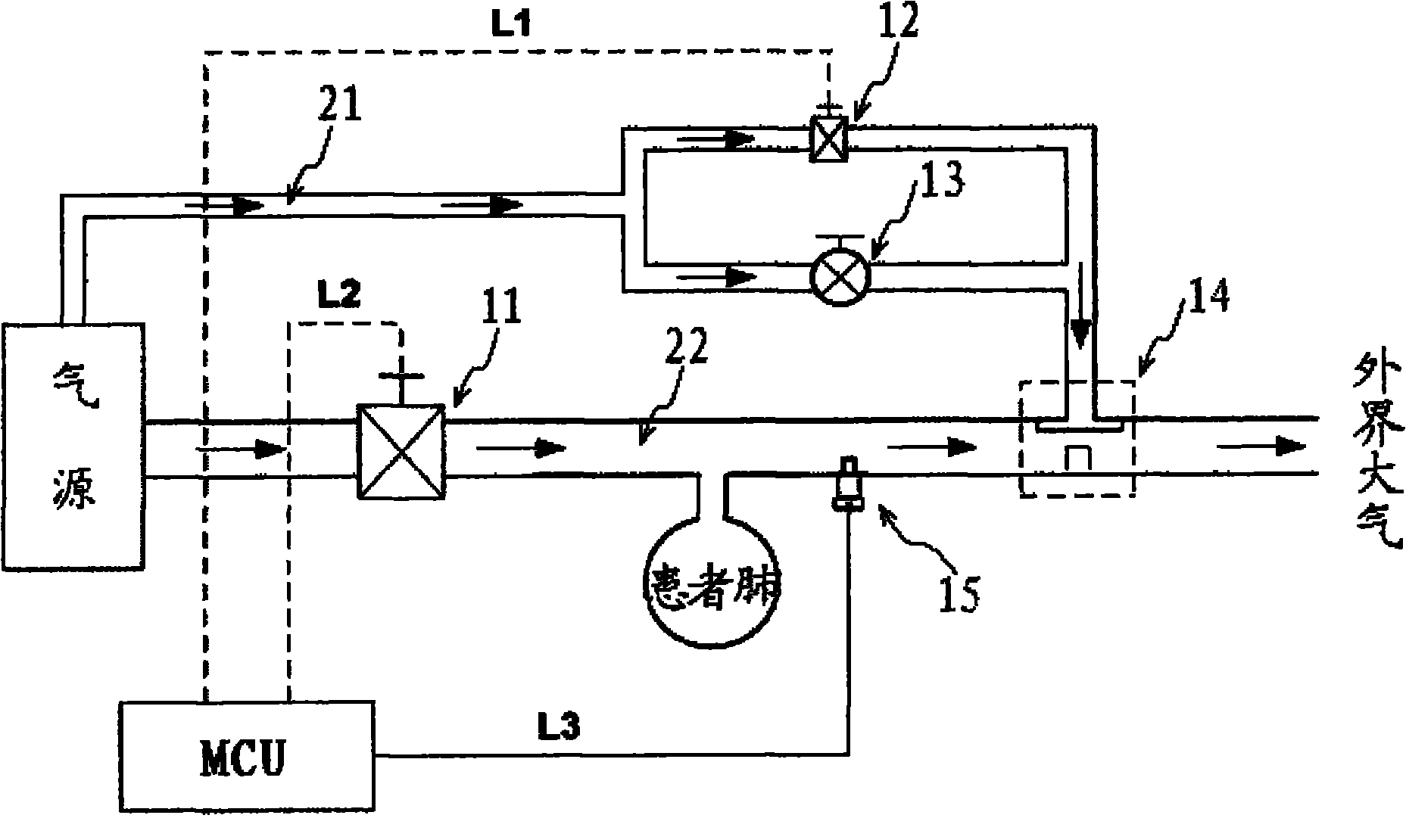

The invention discloses a control method and control system for implementing double horizontal pressures in an air passage. The control method comprises the following steps of: enabling the air inlet end of the air passage to be in a cut-off state or conducting state; enabling the air outlet end of the air passage to be in a cut-off state or conducting state with the external atmosphere by means of an expiratory valve; communicating a control air channel at the control end of the expiratory valve with an air supply source, and keeping the control air channel in a throttling state or full-conducting state, wherein the low-level pressure of the air passage can be set by regulating the throttling quantity of the control air channel in the throttling state; and controlling the state of the air inlet end of the air passage and the state of the control air channel of the expiratory valve in accordance with breath settings and the detected pressure of the air passage. The invention also discloses an anaesthetic machine and breathing machine with the control system. By using the method and system, the invention can completely achieve the functions which can be realized by adopting a proportional valve, an electronic PEEP (Positive End Expiratory Pressure) valve and closed-loop control, and has the advantages of simple design and low cost.

Description

technical field [0001] The present invention relates to a mechanical ventilation method with the goal of controlling pressure, especially a control system and method for realizing bilevel pressure in the airway. equipment. Background technique [0002] The bilevel positive airway pressure ventilation used in common medical equipment is generally realized by proportional valve plus electronic PEEP valve plus closed-loop control. [0003] The dual-level pressure control in the airway is realized by controlling the proportional valve and the electronic PEEP valve through a single chip microcomputer (MCU, Single Chip Microcomputer). [0004] When the MCU finds that the control object is out of tolerance through the relevant pressure sensor, it will adjust the control object in real time through the closed-loop control to achieve the predetermined control target. However, the control process is complicated, the structure is complicated, and the cost is high, which is not conduc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61M16/01A61M16/00A61H31/02

Inventor 刘建军

Owner BEIJING AEONMED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com