Floating bed and manufacture method thereof

A floating bed, press molding technology, applied in the direction of flat products, other household appliances, sports accessories, etc., can solve the problems of complex process, unenvironmental protection, low yield, etc., to achieve the effect of ensuring environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, floating bed and preparation method thereof

[0030] 1. Floating bed

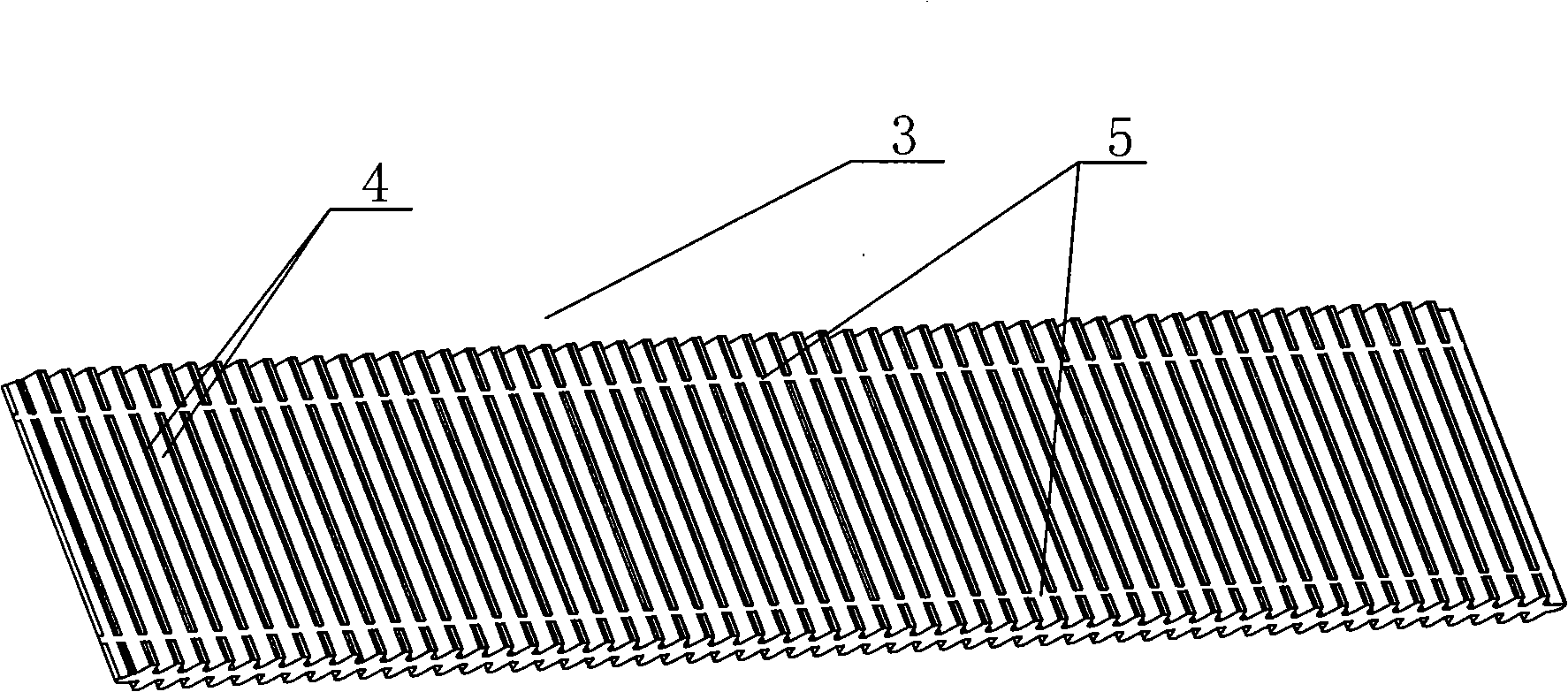

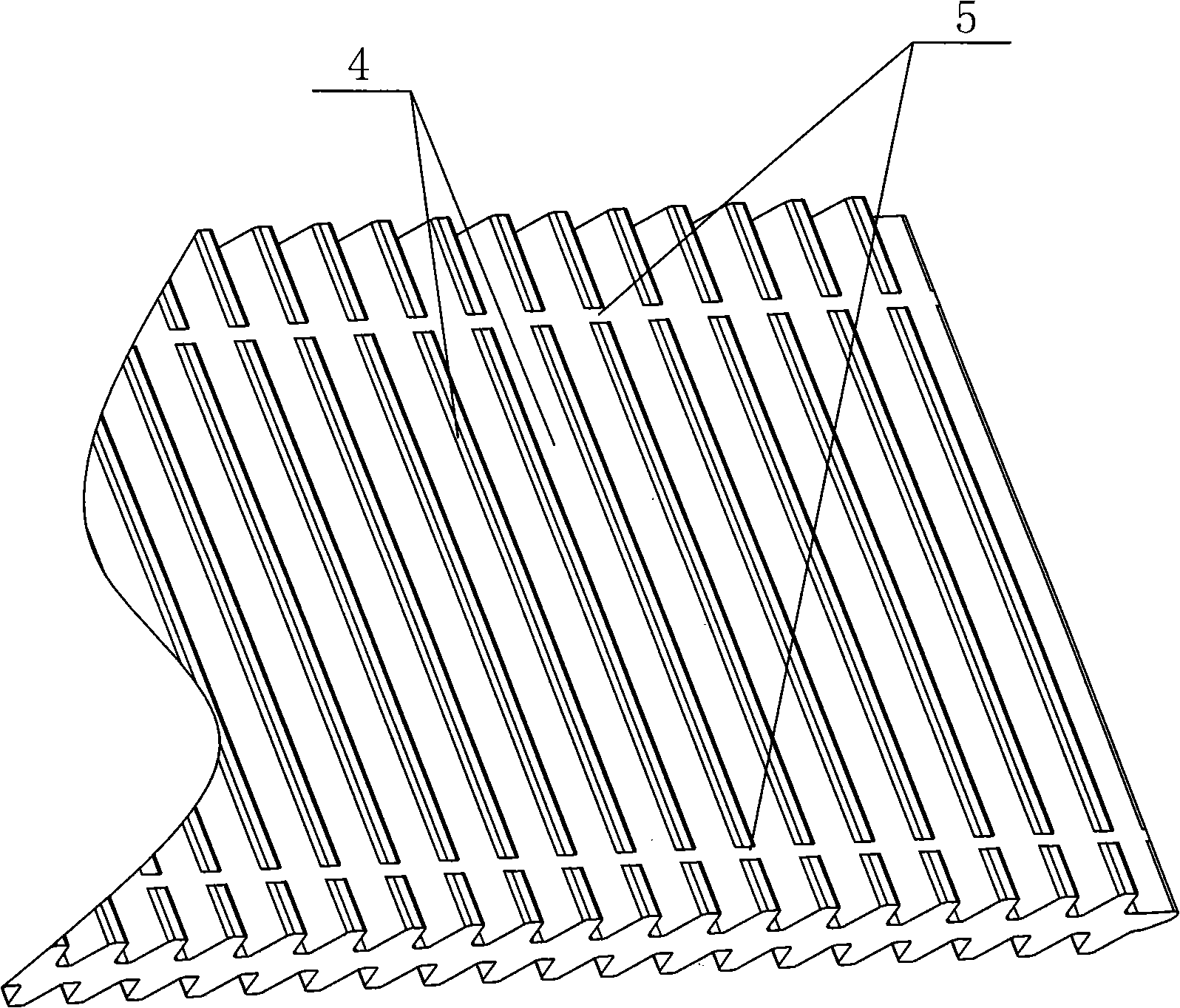

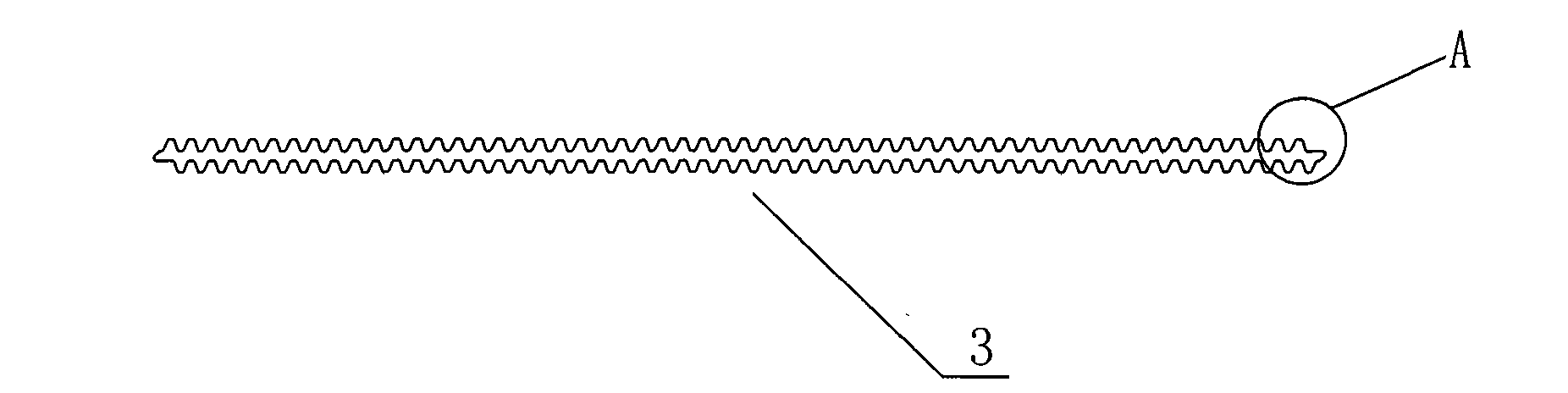

[0031] Such as Figure 1-4 As shown, a floating bed includes a floating bed body 3. The floating bed body 3 is a solid structure and is made of foam material or rubber foam material. The grooves 1 and the protruding teeth 2 are matched with each other and evenly distributed alternately; on both sides of the surface of the floating bed body 3, there are also longitudinal grooves 5 running through the grooves 1 and the protruding teeth 2; the floating bed body 3 is a whole. The above-mentioned floating bed is made of PE foam material.

[0032] 2. Preparation of floating bed

[0033] The preparation method of above-mentioned floating bed comprises the following steps:

[0034] (1) PE foam material is cut into the block of sheet material, and the size of PE foam material cut in the present embodiment is preferably 200 * 71 * 4cm, can also print pattern on PE foam material optionally;

...

Embodiment 2

[0039] Embodiment 2, floating bed and preparation method thereof

[0040] The difference between this embodiment and the floating bed of Embodiment 1 is that the floating bed is made of EVA foam material.

[0041] The method for preparing the present embodiment floating bed is:

[0042] (1) EVA foam is cut into pieces of sheets;

[0043] (2) Put the cut EVA foam sheet into an oven at 190 degrees and bake for 5 minutes;

[0044] (3) Adjust the thickness of the required pressing material according to the requirements of buoyancy, put the baked material into the mold and press it into shape, and the pressing time is 4 minutes;

[0045] (4) Take out the pressed product and trim the side strips to complete the preparation of the product.

Embodiment 3

[0046] Embodiment 3, floating bed and preparation method thereof

[0047] The difference between this embodiment and embodiment 1 is that the preparation method adopted is:

[0048] (1) Cut the PE foam material into sheets;

[0049] (2) Put the cut PE foam sheet into an oven at 230 degrees and bake for 7 minutes;

[0050] (3) Adjust the thickness of the required pressing material according to the requirements of the buoyancy, put the baked material into the mold and press it into shape, and the pressing time is 5 minutes;

[0051] (4) Take out the pressed product and trim the side strips to complete the preparation of the product.

[0052] The foregoing merely illustrate some non-limiting embodiments of the invention, and the specific parameters therein are not the only options for implementing the invention. According to the conventional experience in this field, the baking temperature can be selected from 150 to 230 degrees, the baking time can be controlled from 2 to 7 m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap