Oil separator in compressor

An oil separator and compressor technology, applied in the field of compressors, can solve the problems of complex system, waste of cost, unsatisfactory effect of oil separation and oil separation, etc., and achieve the effect of simplifying system design and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

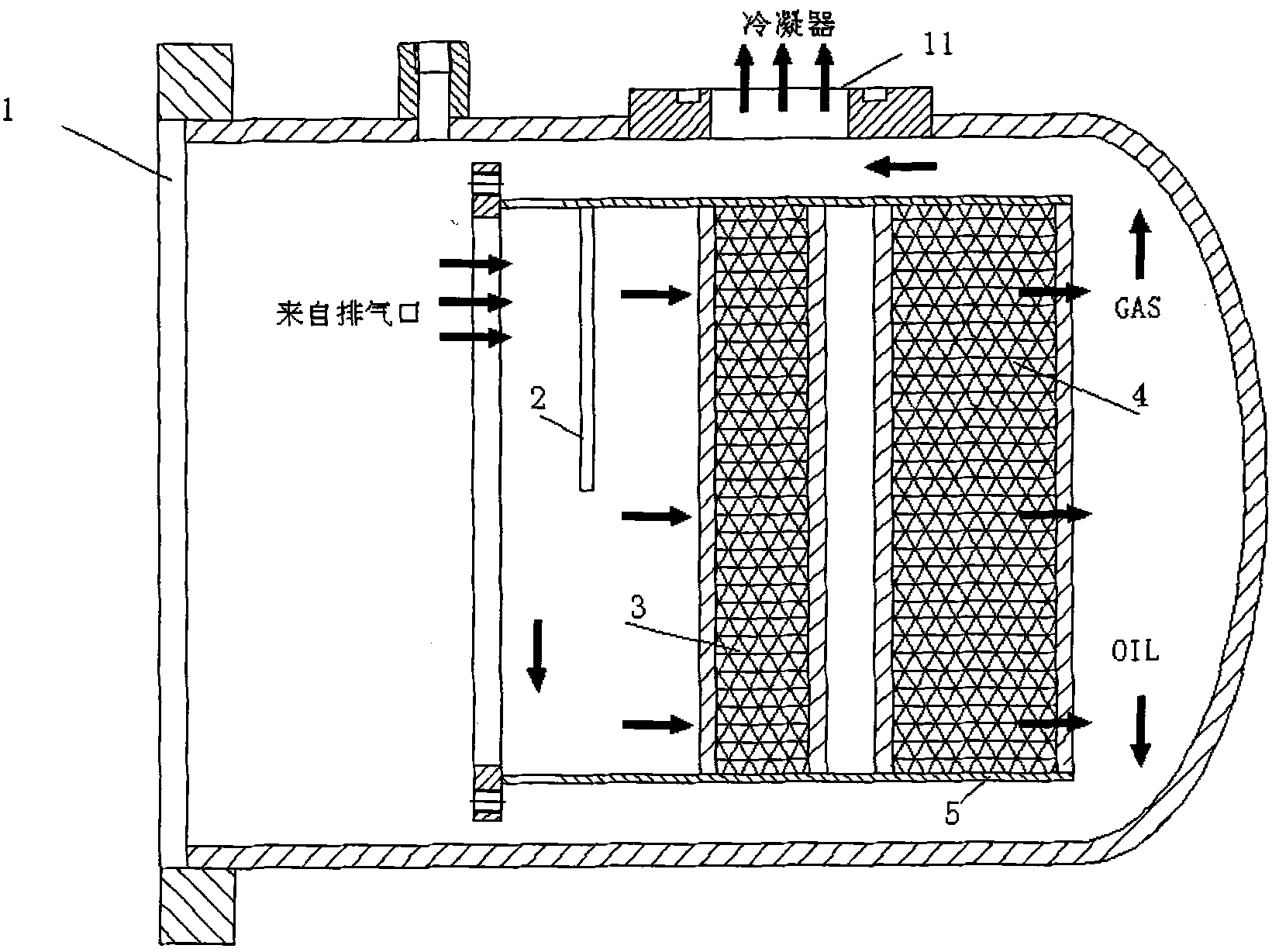

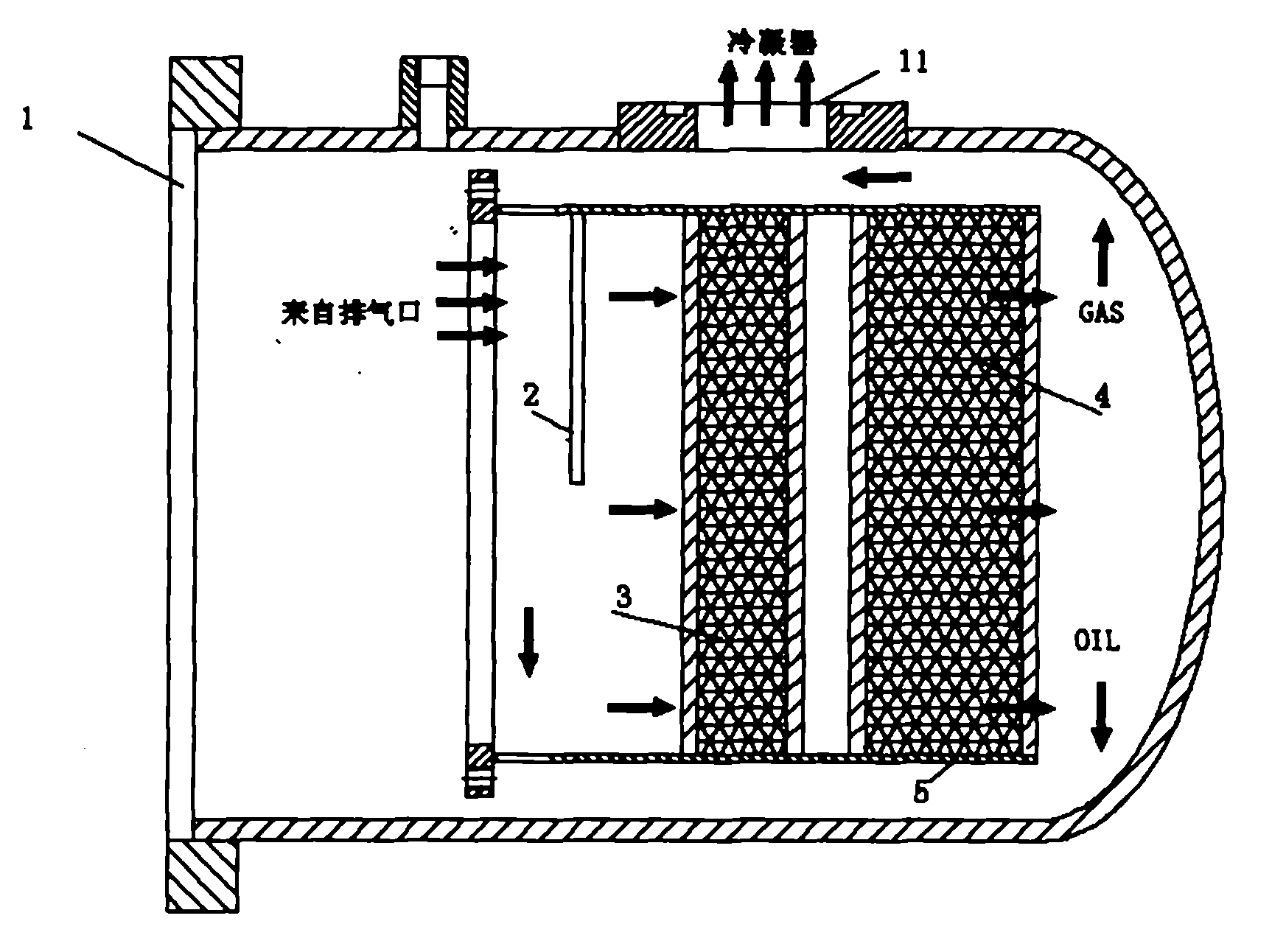

[0009] Depend on figure 1 Visible: the present invention comprises: oil separation shell 1; One side of described oil separation shell 1 has the hole 11 that joins with condenser; An oil drum 5 is fixedly placed in described oil separation shell 1; A baffle plate 2 is arranged at the front end of the barrel 5; one end of the baffle plate 2 is connected with the inner wall of the oil barrel 5, and the other end of the baffle plate 2 has a distance from the corresponding inner wall of the oil barrel 5; It is the first filter screen 3 connected to the inner wall of the oil barrel 5; the distance from the first filter screen 3 also includes the second filter screen 4 connected to the inner wall of the oil drum 5.

[0010] The oil separation casing in the present invention is at the outermost side of the whole structure, the oil barrel is inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com