Energy-saving unpowered lower opening type tyre vulcanizing segmented mold

A tire vulcanization and flexible mold technology, applied in tires, household appliances, other household appliances, etc., can solve problems such as waste of power energy, personal injury, safety hazards, etc., to save equipment costs, solve safety hazards, and save power and energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

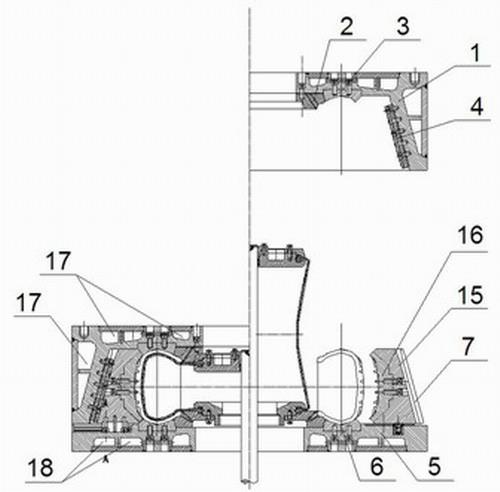

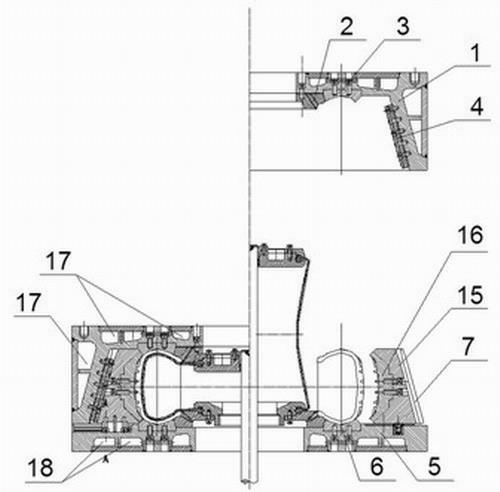

[0017] An energy-saving unpowered bottom-opening tire vulcanization active mold, including a vulcanization upper die, a vulcanization lower die and an active joint module, characterized in that: the vulcanization upper die includes an upper tapered mold case 1, and the upper tapered die case The upper steel ring 2 and the upper tire side plate 3 are fixedly installed on the upper surface of the inner side, and a guide block 4 is installed on the inner conical surface of the upper tapered die sleeve. The lower tire side plate 6 on the bottom plate of the movable mold, the movable module is connected to the bottom plate of the lower movable mold and realizes radial movement through the radial sliding device arranged on the bottom plate of the lower movable mold, and the outer surface of the movable module is also provided with The inclined guide groove 7 matched with the guide block.

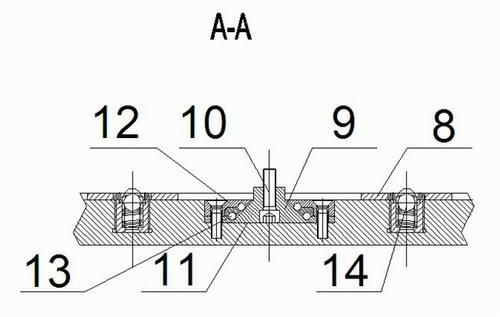

[0018] The radial sliding device includes a plane guide friction plate 8 fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com